The Bobcat A300 is a versatile and powerful machine known for its ability to handle difficult tasks in a wide range of environments. However, like any piece of machinery, it can encounter various problems over time. Understanding common issues associated with the Bobcat A300 is crucial for maintaining its performance and ensuring its longevity. This article will delve into the frequent problems, symptoms, causes, diagnosis steps, troubleshooting, and repair procedures relevant to the Bobcat A300, along with tips on prevention and when it's necessary to seek professional help.

Key Takeaways

- The Bobcat A300 is prone to several mechanical and electrical issues, including hydraulic failures, engine troubles, and electrical malfunctions.

- Common symptoms that indicate a problem may arise include unusual noises, failure to start, and erratic performance.

- Regular maintenance and proper operation can help prevent many of these issues.

- Understanding common error codes can aid in diagnosing problems quickly.

- DIY repairs can be cost-effective but knowing when to seek professional assistance is crucial.

| Symptoms | Possible Causes |

|---|---|

| Failure to start | Weak battery, defective starter motor, fuel issues |

| Hydraulic issues | Low fluid, leaks, faulty pump |

| Unusual engine noises | Worn components, misfiring |

| Overheating | Low coolant, clogged radiator |

| Erratic hydraulic performance | Air in the system, dirty filters |

Problem Description

The Bobcat A300, equipped with a powerful 81 horsepower engine, is designed for heavy-duty tasks and is built to withstand tough working conditions. However, users may encounter a variety of problems, which can range from minor inconveniences to major malfunctions. Issues can stem from electrical systems, hydraulic components, engines, and general wear and tear. Understanding these problems is vital for ensuring safety and efficiency in work operations.

Common problems associated with the Bobcat A300 include:

- Hydraulic system failures

- Engine performance issues

- Starting difficulties

- Electrical malfunctions

- Transmission problems

Each of these issues can lead to significant downtime and increased operational costs if not addressed promptly.

Common Symptoms

Identifying the symptoms of problems early on can save time and money. Here are some common indicators:

- Failure to Start: If the A300 struggles to start or doesn’t start at all, it could be a battery, starter, or fuel issue.

- Unusual Noises: Grinding or clunking sounds can indicate wear in components that may need replacement.

- Hydraulic Performance Issues: Slow or unresponsive hydraulics can signal low fluid levels or pump failure.

- Engine Overheating: An overheating engine can lead to severe damage if not resolved immediately.

- Warning Lights: Error codes and indicators on the dashboard should be monitored, as they can provide insights into underlying issues.

Possible Causes

Understanding the root causes of these symptoms is essential for effective troubleshooting. Here are some potential causes:

-

Starting Problems:

- Weak or dead battery.

- Faulty starter motor.

- Fuel delivery issues (clogged filter or pump failure).

-

Hydraulic Issues:

- Low hydraulic fluid levels or leaks in the system.

- Clogged hydraulic filters.

- Faulty hydraulic pump or hoses.

-

Engine Performance:

- Worn spark plugs or faulty injectors.

- Fuel system issues (contaminated or low fuel).

- Air intake restrictions.

-

Electrical Malfunctions:

- Faulty wiring or connections.

- Defective sensors.

Identifying these causes will facilitate a more directed diagnosis and solution approach.

Diagnosis Steps

Diagnosing issues with the Bobcat A300 requires a systematic approach. Here are steps to follow:

-

Perform Visual Inspections:

- Check for obvious signs of leaks or wear.

- Inspect the battery terminals for corrosion.

-

Check Error Codes:

- Use an OBD-II scanner to read engine error codes.

- Address any faults indicated by the codes.

-

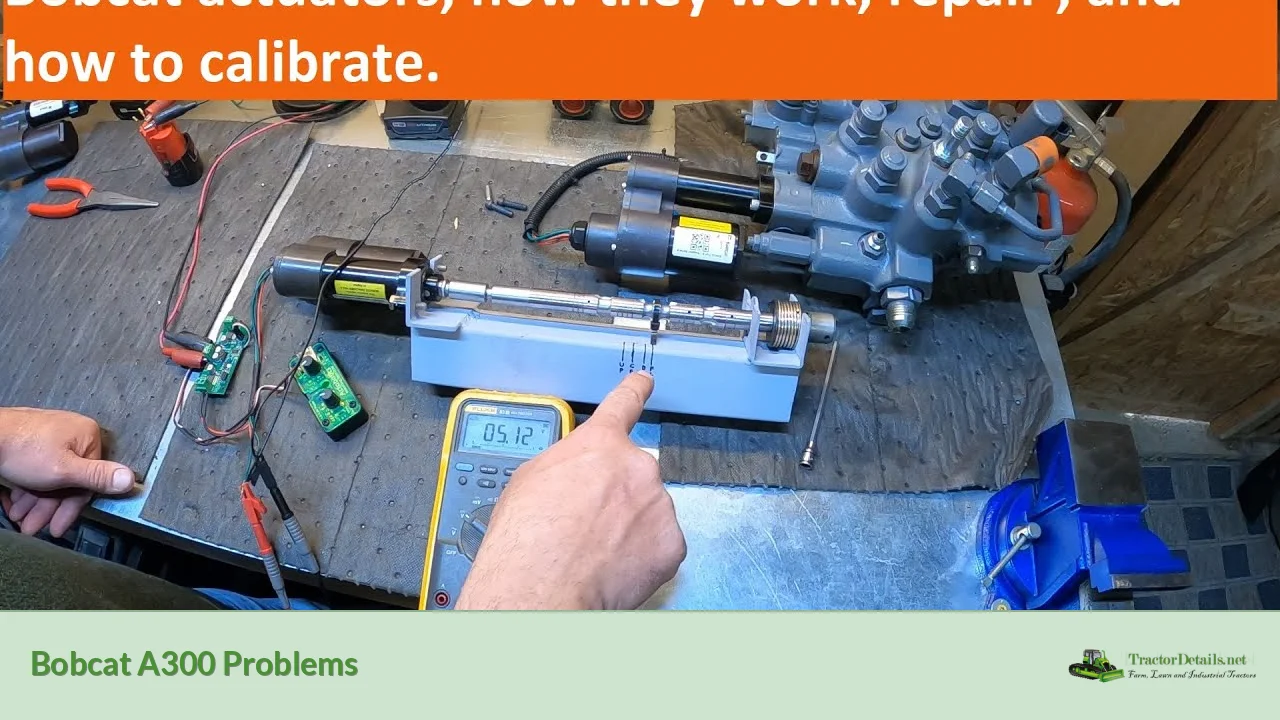

Test Battery Voltage:

- Measure the battery voltage using a multimeter.

- Ensure it provides adequate voltage (around 12.6V).

-

Evaluate Fluid Levels:

- Inspect hydraulic fluid and coolant levels.

- Fill as needed, and check for any leaks.

-

Inspect Fuel System:

- Check fuel filter for clogs.

- Inspect fuel lines for any damages.

-

Listen for Strange Noises:

- Start the engine and listen for any abnormal sounds, which can indicate mechanical issues.

Troubleshooting and Repair Procedures

Once the diagnosis is complete, the subsequent troubleshooting and repair steps can be broken down into several areas:

Starting Issues

- Dead Battery: Charge or replace the battery as necessary.

- Starter Motor Failure: Replace the starter if it shows signs of failure.

- Fuel Delivery Problems: Replace the fuel filter and inspect the fuel lines for leaks or blockages.

Hydraulic Problems

- Low Fluid: Refill hydraulic fluid as per manufacturer specifications.

- Pump Replacement: If the pump is faulty, it will require professional replacement.

- Leak Repairs: Fix any leaks found in hoses or connections.

Engine Performance

- Tune-Up: Replace spark plugs and filters to maintain performance.

- Fuel System Cleaning: Use fuel additives to clean injectors and lines.

Electrical Issues

- Wiring Inspection: Repair any frayed or broken wires within the electrical system.

- Sensor Replacement: Replace faulty sensors that lead to incorrect readings.

Estimated Repair Costs

Repairs can vary significantly in cost, depending on parts and labor. Here’s a rough breakdown:

- Battery Replacement: $150 - $300

- Starter Motor: $200 - $500

- Hydraulic Pump: $800 - $1,500

- Tune-Up (plugs/filters): $200 - $400

- Electrical Issues: $150 - $600, depending on the extent of repairs needed.

DIY repairs can significantly reduce these costs, but it’s important to be realistic about your skills and the tools required.

Prevention Tips

Preventative maintenance can help minimize problems in the future. Here are some effective tips:

- Regular Inspections: Perform visual checks of fluid levels, belts, and hoses at least monthly.

- Routine Maintenance: Follow the manufacturer’s maintenance schedule for oil changes, filter replacements, and inspections.

- Proper Usage: Ensure operators are trained in the proper use of the machine to prevent misuse and excessive wear.

- Store Properly: Keep the Bobcat A300 in a dry, preferably sheltered area to minimize weather-related damage.

When to Seek Professional Help

While many repairs can be tackled DIY, some issues may require professional expertise:

- Complex Hydraulic Repairs: If hydraulic issues persist or are extensive, getting a professional involved can save time and ensure proper repairs.

- Engine Rebuilds: Significant engine failures warrant professional diagnosis and repairs.

- Electrical Diagnostics: If you are uncomfortable working with electrical systems, it’s best to consult with a certified technician.

Conclusion

The Bobcat A300 is a robust machine, but like any heavy equipment, it is not without its challenges. By understanding the common problems—ranging from starting issues to hydraulic failures—and recognizing the symptoms that indicate trouble, operators can effectively maintain their machines. Regular maintenance and timely repairs can prevent minor issues from escalating into costly breakdowns.

Always prioritize safety and efficiency by staying informed and proactive about potential problems, and don’t hesitate to seek professional assistance when required. Taking these steps will ensure that your Bobcat A300 remains reliable and performs effectively even in the toughest conditions.Of course! Could you please provide more context or let me know what you would like to continue discussing?