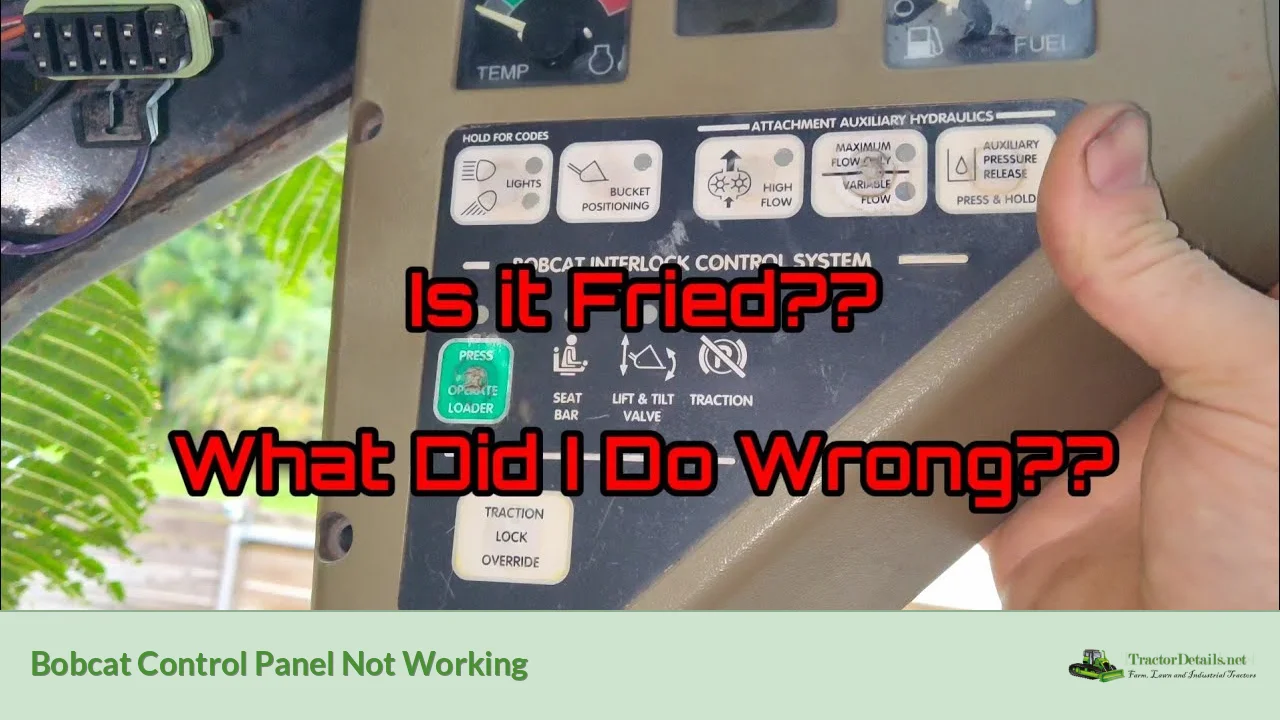

Bobcat control panels are essential components of Bobcat equipment, providing users with the ability to monitor and control various functions effectively. When a Bobcat control panel is not working, it can lead to significant operational downtime, affecting productivity and efficiency. This article aims to help Bobcat owners understand the common issues related to control panel failures, diagnose problems efficiently, and outline troubleshooting steps along with potential repair procedures.

Key Takeaways

- A malfunctioning Bobcat control panel can lead to equipment inefficiency and operational downtime.

- Common symptoms include unresponsive buttons, error codes, and intermittent functionality.

- Possible causes can range from electrical issues, fuse failures, or software problems.

- DIY troubleshooting and repair might be possible for some issues, but others may require professional assistance.

- Regular maintenance can help prevent control panel issues.

Problem Description

A malfunctioning control panel in Bobcat machinery, such as the Bobcat E Series excavators or the S Series skid-steer loaders, can arise from various factors. Understanding the symptoms and potential causes is crucial for identifying the root of the problem effectively. Control panels serve as the interface for operators to manage hydraulic functions, monitor engine status, and adjust various settings. When this crucial component fails, the entire operation can come to a halt.

Common Symptoms

Below are some of the common symptoms that indicate a control panel issue:

| Symptoms | Possible Causes |

|---|---|

| Unresponsive buttons | Faulty wiring or connections |

| Display screen blank | Power supply issue or blown fuse |

| Error codes displayed | Software error or sensor malfunction |

| Inconsistent performance | Corroded connectors or moisture ingress |

| Backlight not functioning | Failed LED or poor electrical ground |

Observing these symptoms can help narrow down the potential causes and lead to quicker resolutions.

Possible Causes

The causes for a non-working Bobcat control panel can stem from either electrical or mechanical issues. Here are the most common reasons:

-

Electrical Issues:

- Loose or corroded connections can interrupt power flow to the panel.

- Blown fuses can cause the panel to lose all functionality.

- Battery or alternator problems affecting power supply.

-

Software Problems:

- Faulty firmware can lead to the control panel not responding properly.

- Corrupted settings due to previous errors.

-

Mechanical Problems:

- Moisture ingress into the control panel might cause shorts or malfunctions.

- Physical damage due to wear and tear or accidents.

Diagnosis Steps

To accurately diagnose the problem with your Bobcat control panel, follow these systematic steps:

-

Check Power Supply:

- Verify that the equipment is receiving power. Inspect the battery and connections.

- Look for blown fuses in the electrical panel.

-

Inspect Wiring and Connections:

- Examine all wiring leading to the control panel for signs of wear or corrosion.

- Ensure all connectors are seated properly and free from dirt and moisture.

-

Look at Error Codes:

- Refer to the user manual for any error codes displayed on the panel.

- Common error codes may include “U01,” which typically indicates communication issues between the panel and the machine's ECU.

-

Test Components:

- Use a multimeter to check the voltage at the panel connectors.

- Inspect the control panel circuit board for any visible damage.

-

Software Reset:

- Perform a soft reset of the control panel if applicable. This can sometimes clear software glitches.

Troubleshooting and Repair Procedures

Once you have diagnosed the common issues related to your Bobcat control panel, you can proceed with the following troubleshooting and repair steps:

DIY Solutions

-

Replacing Fuses:

- Locate the fuse box and replace any blown fuses.

- Use fuses that meet manufacturer specifications to ensure safety.

-

Cleaning Connections:

- Disconnect the battery before cleaning connectors and sockets.

- Use a wire brush or electrical cleaner to remove corrosion.

-

Check Wiring:

- If cable insulation is damaged, replace the wiring.

- Ensure all ground connections are secure and free from rust.

-

Software Update:

- Download software updates from the Bobcat website.

- Follow the manufacturer’s instructions for resetting the control panel.

Professional Repair Options

If the above steps do not resolve the issue, it may be necessary to seek professional help. Here are the options available:

-

Certified Bobcat Technicians:

- They can perform a comprehensive diagnostic and maintenance check.

- Technicians have access to specialized tools and software for deeper analysis.

-

Local Equipment Repair Shops:

- Many local shops offer repair services for Bobcat machinery.

- Ensure the technicians are familiar with Bobcat systems to avoid further issues.

Estimated Repair Costs

The costs associated with repairing a Bobcat control panel can vary widely based on the nature and extent of the problem. Here’s a rough breakdown of potential costs:

-

DIY Repairs:

- Fuses: $5 to $20

- Wiring and connectors: $20 to $100

- Software updates: Free to $50 (depending on model)

-

Professional Repairs:

- Diagnostic fees: $75 to $150 per hour

- Control panel replacement: $500 to $1500, depending on the model

- Additional repair costs: $100 to $500 based on issues diagnosed

Note: Always get a detailed estimate from a professional before approving any repairs to ensure transparency and avoid unexpected costs.

Prevention Tips

Preventive measures can help reduce the likelihood of control panel issues. Here are some tips to consider:

-

Regular Maintenance:

- Schedule routine inspections to identify wear and tear early.

- Clean and lubricate connections to prevent corrosion.

-

Use Proper Storage:

- Store Bobcat equipment indoors or use protective covers to shield from moisture and debris.

-

Monitor Operating Conditions:

- Avoid using equipment in extreme weather conditions that can impact electronics.

- Pay attention to any unusual performance indicators and address them promptly.

When to Seek Professional Help

While some repairs can be tackled as DIY projects, certain situations warrant professional assistance:

-

Complex Electrical Issues:

- If you identify multiple electrical problems or nuances that are beyond your expertise.

-

Software Malfunctions:

- When the control panel fails to respond to resets or updates cannot be performed due to errors.

-

Persistent Error Codes:

- If error codes reappear consistently despite attempted fixes, further diagnostics are necessary.

Conclusion

In summary, a non-functional Bobcat control panel can disrupt operations and affect overall productivity. Identifying symptoms, understanding potential causes, and following detailed diagnostic and troubleshooting steps can help mitigate issues effectively. For those comfortable with DIY repairs, basic issues like blown fuses and wiring problems can often be rectified without professional intervention. However, it is essential to recognize when expert help is needed to ensure the longevity and reliability of your equipment.

Maintain your Bobcat machinery with regular checks, follow proper usage guidelines, and stay informed about potential issues to prevent control panel failures in the future. By taking these proactive steps, Bobcat owners can enhance their operational efficiency and minimize downtime significantly.It seems like you would like me to continue with something, but I need a bit more context to assist you properly. Could you please provide more details or specify what you would like to continue with? Whether it's a story, a conversation, or a different topic, I’m here to help!