Bobcat Joystick Problems can significantly impact the efficiency and safety of operating these powerful machines. As one of the leading brands in compact equipment, Bobcat's joystick controls are essential for maneuvering their skid-steer loaders, excavators, and other machinery. While these controls are typically reliable, users may encounter various issues affecting responsiveness or functionality over time. Recognizing and rectifying these problems quickly can prevent more severe malfunctions and costly repairs down the road.

Key Takeaways

- Joystick issues can arise from hardware failure, electrical malfunctions, or software glitches.

- Common symptoms include unresponsive controls, erratic movements, or error codes.

- Proper diagnosis requires methodical troubleshooting steps, often beginning with visual inspections.

- Users can perform basic repairs, but in complex cases, professional assistance is recommended.

| Symptoms | Possible Causes |

|---|---|

| Unresponsive joystick | Faulty joystick sensor |

| Erratic or jerky movements | Electrical connection issues |

| Intermittent operation | Software glitches |

| Error codes displayed | Faulty control module |

| Excessive wear on controls | Physical damage or wear |

Problem Description

Bobcat machinery is designed to facilitate a broad range of construction and landscaping tasks through intuitive joystick controls. The joystick manages various functions including steering, lifting, and tilting. However, problems with the joystick can lead to operational challenges, potentially endangering both the operator and the machinery itself. Commonly encountered problems may manifest as reduced control precision or unexpected machine behavior.

Common Symptoms

Identifying the symptoms of joystick problems early can save time and money:

- Unresponsive Controls: The joystick may not register input when moved.

- Erratic Movements: The machine may respond in unexpected ways, such as moving forward or backward without input.

- Intermittent Operation: The joystick may work sporadically, leading to frustrating and unpredictable machine behavior.

- Error Codes: The control panel may display specific error codes that can indicate the nature of the issue.

- Physical Wear: Signs of wear on the joystick or surrounding components may indicate a need for maintenance.

Possible Causes

Understanding what could be causing these symptoms is crucial for effective troubleshooting:

- Faulty Joystick Sensor: The internal sensor that detects movement may have failed.

- Electrical Connection Issues: Corroded or loose wiring could disrupt the electrical signals.

- Software Glitches: Firmware or software issues in the control system can lead to functionality problems.

- Faulty Control Module: A malfunctioning control module may misinterpret joystick inputs.

- Physical Damage: Dropping the joystick or exposure to harsh conditions may cause functional damage.

Diagnosis Steps

Correctly diagnosing joystick issues is essential. Follow these step-by-step guidelines:

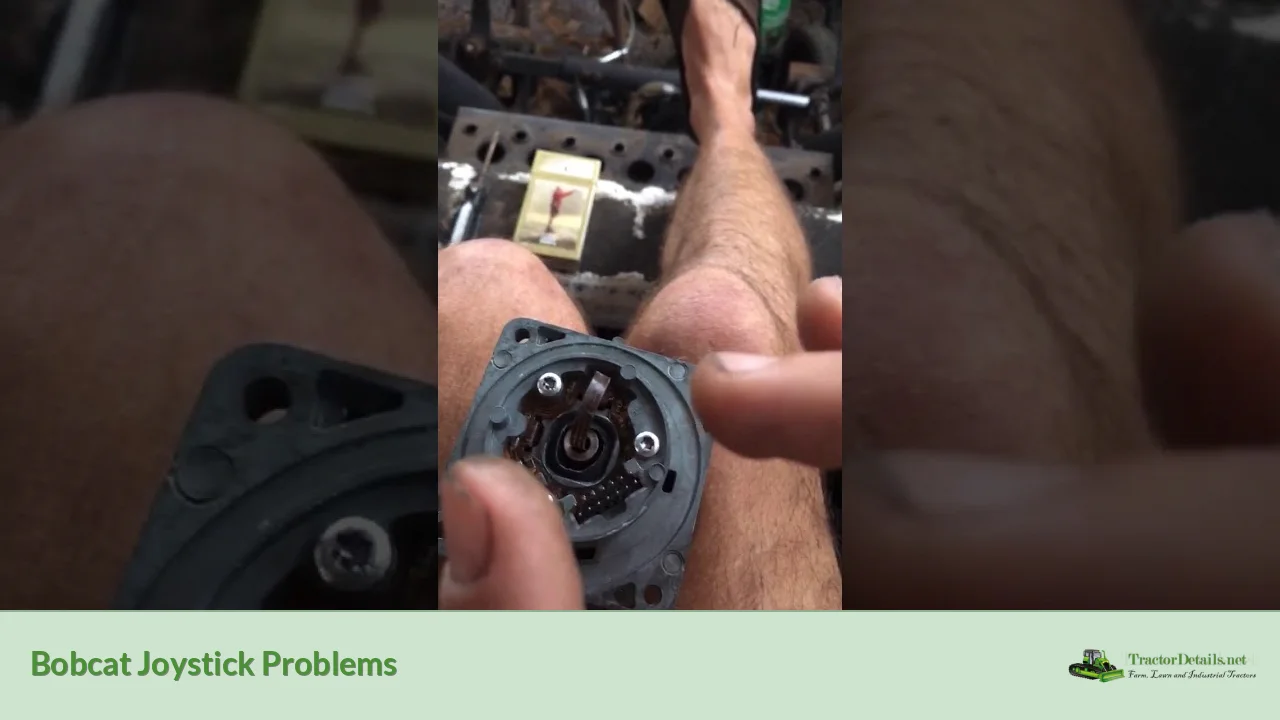

- Visual Inspection: Check the joystick and surrounding components for visible signs of damage or wear.

- Check Connections: Inspect the wiring and connections to ensure everything is secure and free from corrosion.

- Error Code Retrieval: Use the machine’s diagnostic tools to pull any saved error codes, which can direct you to specific issues.

- Test Joystick Functionality: If feasible, manually test the joystick's movements to see if there are areas of resistance or irregular feedback.

- Review Software Settings: If available, check the manufacturer's software updates or parameters to ensure the joystick is configured correctly.

Troubleshooting and Repair Procedures

Once you've identified the issue, follow these troubleshooting steps:

- Clean Connections: Use electrical contact cleaner on terminals and connectors.

- Replace Worn Parts: If you find that components are worn out, consider replacing them with OEM parts.

- Check the Control Module: If DIY efforts fail, you may need to replace the control module. Ensure you follow the manufacturer's specifications during this process.

- Calibrate Joystick: If the joystick is functioning but not accurately, proceed to calibrate it using the machine's onboard controls.

- Reinstall Software: In cases of software errors, reinstalling or updating the control software may be necessary.

Estimated Repair Costs

Repair costs can vary widely based on the issue:

- Simple Fixes (Cleaning connections, replacing minor components): $50 - $200

- Joystick Replacement: $200 - $600 depending on the make and model.

- Control Module Replacement: $400 - $1,200, especially for complex machines.

- Professional Service: Costs can rise to $100 - $150 per hour depending on technician expertise and location.

Prevention Tips

To minimize the risk of future joystick problems, consider the following preventive measures:

- Regular Maintenance: Schedule routine inspections and maintenance of your machinery.

- Clean Connections: Periodically check and clean electrical connections to prevent corrosion.

- Training: Ensure operators are well-trained and informed about the appropriate use of joystick controls.

- Environmental Protection: Guard the joystick against harsh environmental conditions, especially if the machine is frequently outside.

- Timely Updates: Always install software updates provided by Bobcat to enhance performance and resolve potential issues.

When to Seek Professional Help

While many joystick issues can be resolved through troubleshooting, certain circumstances warrant professional assistance:

- Persistent Error Codes: If error codes continue to appear despite attempts to rectify them, consult a technician.

- Complex Malfunctions: If the joystick shows signs of critical failure, such as complete unresponsiveness, a professional assessment is vital.

- Electrical Problems: For issues related to wiring or the control module, expertise is necessary to avoid further damage to the system.

- Calibrating and Programming: If you're unsure about recalibrating or updating software, it's best to leave it to the professionals.

Conclusion

Bobcat joystick problems are an unfortunate but manageable aspect of owning and operating heavy machinery. By being vigilant about identifying symptoms early, understanding possible causes, and employing proper troubleshooting techniques, machine owners can avoid significant downtime. Investing in regular maintenance, recognizing the signs of failure, and knowing when to seek professional help are key strategies for ensuring optimal performance. Take the time to familiarize yourself with your Bobcat's joystick system, and you’ll be better prepared to address any problems that arise efficiently and effectively.It seems like your message got cut off. Could you please provide more details or clarify what you would like me to continue with?