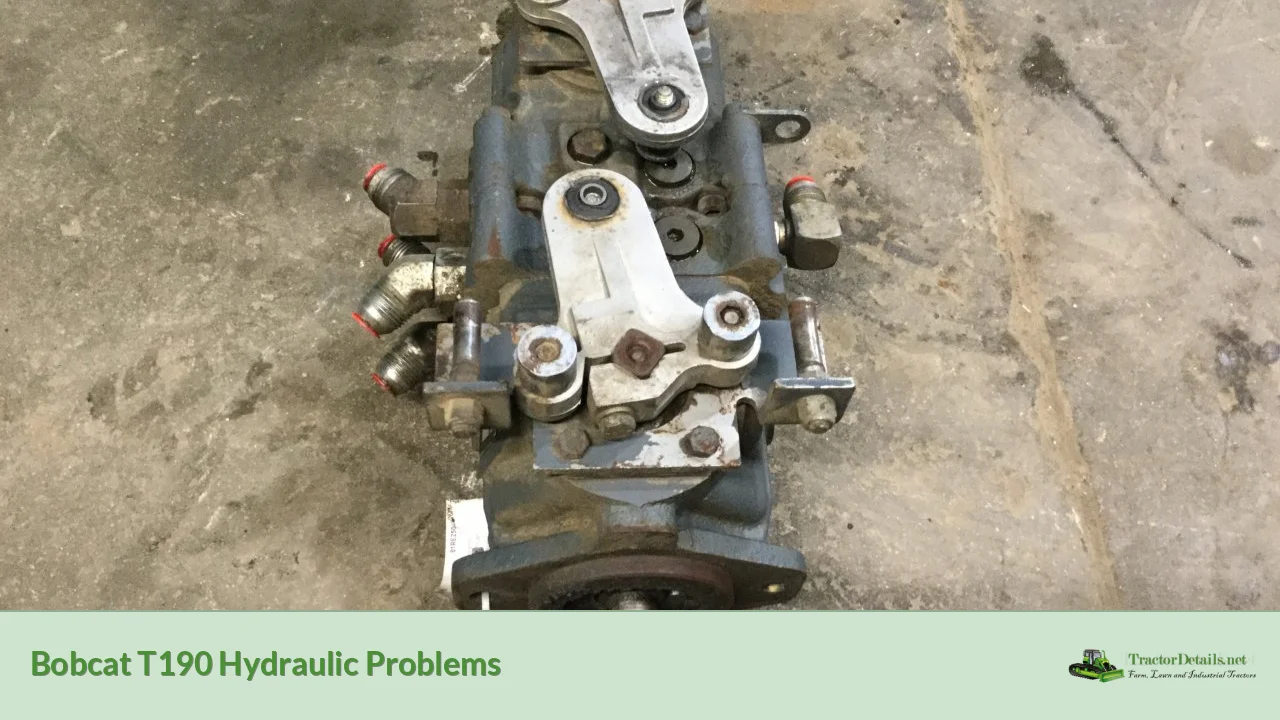

Bobcat T190 hydraulic problems can lead to reduced performance and functionality of this robust compact track loader. As one of the most popular models in the Bobcat lineup, the T190 is known for its versatility in various applications, including landscaping, construction, and agricultural tasks. However, hydraulic issues can emerge over time due to wear and tear or lack of maintenance. It’s crucial for operators to understand these problems to effectively troubleshoot and solve them.

Key Takeaways

- Hydraulic issues generally arise from leaks, air in the system, or faulty components.

- Common symptoms include inconsistent lifting power, slow or jerky movements, and unresponsive attachments.

- Routine maintenance can significantly decrease the likelihood of hydraulic problems.

- Understanding diagnostic codes can help pinpoint issues swiftly.

| Common Symptoms | Possible Causes |

|---|---|

| Inconsistent lifting power | Hydraulic fluid leaks |

| Slow or jerky movements | Air in the hydraulic system |

| Unresponsive attachments | Faulty hydraulic pump |

| Overheating of the hydraulic system | Clogged filters |

| Unusual noises during operation | Low hydraulic fluid levels |

Problem Description

The hydraulic system in the Bobcat T190 is vital for its operation, allowing the loader to lift, tilt, and maneuver various attachments. When hydraulic issues arise, they can lead to significant operational difficulties, affecting productivity and safety. Operators may notice a decrease in lifting capabilities or erratic movements, which can halt work and cause frustration.

Key Points:

- Hydraulic systems are complex and can fail for various reasons.

- Timely identification of symptoms can save time and costs.

- Regular maintenance is key to preventing hydraulic issues.

Common Symptoms

Hydraulic issues can manifest in several ways. Recognizing these signs early can help avoid further damage and costly repairs.

- Inconsistent lifting power: If the loader struggles to lift loads that it previously could, this is a clear indicator of a hydraulic problem.

- Slow or jerky movements: When the loader’s movements are not smooth and instead feel sluggish or abrupt, it often signals internal leakage or air in the system.

- Unresponsive attachments: If attachments fail to work properly (e.g., a bucket doesn’t tilt as expected), it could be an issue with the hydraulic control valves.

- Overheating: Continuous use of the loader without addressing hydraulic problems can lead to overheating, which may cause complete system failure.

- Unusual noises: If operators hear grinding, whining, or popping noises while operating the hydraulic system, it can indicate serious issues with the components.

Possible Causes

Hydraulic problems in the Bobcat T190 can stem from multiple sources. Understanding these can guide operators towards effective solutions.

- Hydraulic fluid leaks: Fittings, hoses, and seals can wear out or get damaged, leading to fluid loss and reduced pressure in the system.

- Air in the hydraulic system: If there is air trapped within the hydraulic lines, it can disrupt the flow of hydraulic fluid, causing operational issues.

- Faulty hydraulic pump: A malfunctioning pump may not generate sufficient pressure, impacting the loader's performance.

- Clogged filters: Filters that are dirty or clogged can restrict fluid flow, leading to performance degradation.

- Low hydraulic fluid levels: Insufficient fluid quantity can cause aeration and overheating, severely affecting functionality.

Diagnosis Steps

To diagnose hydraulic problems in the Bobcat T190, follow these systematic steps:

-

Visual Inspection:

- Check for visible hydraulic fluid leaks around hoses, fittings, and seals.

- Examine hydraulic fluid levels in the reservoir.

-

Check for Air in the System:

- Bleed the hydraulic system to remove any trapped air.

- Operate the loader with attachments to see if performance improves.

-

Inspect Hydraulic Filters:

- Remove and inspect hydraulic filters for clogs.

- Replace filters if they appear dirty or restricted.

-

Test the Hydraulic Pump:

- Use a pressure gauge to check pump output.

- If pressure is below specifications, the pump may need repairs or replacement.

-

Examine Hydraulic Control Valves:

- Inspect control valves for leaks and functionality.

- Ensure that they are engaging and disengaging properly.

Troubleshooting and Repair Procedures

Once the diagnosis is complete, appropriate troubleshooting and repairs can be enacted.

DIY Solutions:

- Leak Repairs:

- Tighten any loose fittings and replace damaged hoses or seals.

- Fluid Changes:

- Drain old hydraulic fluid, clean the reservoir, and refill with manufacturer-recommended fluid.

- Filter Replacement:

- Follow manufacturer guidelines to replace filters. Ensure new filters meet OEM standards.

- Bleeding the System:

- Operate all attachments to thoroughly bleed the system following fluid replacement.

Professional Repair Options:

- Hydraulic Pump Replacement:

- If the pump is faulty, consider hiring a professional to replace it as it often involves complicated disassembly.

- Valves Repair/Replacement:

- Defective valves may require expert repair. Seek certified Bobcat technicians or authorized dealers.

- System Flush:

- For severe contamination issues, having a professional flush the entire hydraulic system can restore performance.

Recommended Tools for DIY Repair:

- Wrench set

- Screwdrivers

- Hydraulic fluid

- Replacement filters

- Pressure gauge

- Hoses and seals

Estimated Repair Costs

Repair costs for hydraulic problems in the Bobcat T190 can vary widely depending on the complexity of the issue and labor rates in your area. Here is a rough estimate of potential costs:

- Hydraulic Fluid Change: $100-$300

- Filter Replacement: $50-$200 (including labor)

- Hydraulic Pump Replacement: $500-$2,000 (including parts and labor)

- Valve Repair/Replacement: $300-$1,500

Keep in mind that costs can escalate if multiple components require attention or if extensive refurbishing is necessary.

Prevention Tips

To minimize the occurrence of hydraulic problems in your Bobcat T190, consider the following preventive measures:

-

Regular Maintenance:

- Schedule routine inspections and maintenance every 200 hours of operation or as recommended by the manufacturer.

-

Frequent Fluid Checks:

- Monitor fluid levels between uses to ensure they remain adequate. Use only the OEM-recommended hydraulic fluid.

-

Promptly Address Leaks:

- Inspect and repair leaks immediately to avoid pressure loss. Use a hydraulic oil dye to identify hard-to-spot leaks.

-

Clean Environment:

- Keep the machine and surrounding areas free of dirt and debris to prevent contaminants from entering the hydraulic system.

-

Educate Operators:

- Train operators on proper usage and the importance of reporting symptoms early on.

When to Seek Professional Help

While many hydraulic issues can be addressed through DIY methods, some situations warrant professional intervention. Seek expert help in the following scenarios:

- Persistent Problems: If hydraulic issues persist despite basic troubleshooting and repairs.

- Complex Systems: When a malfunction involves intricate components like the hydraulic pump or control valves.

- Safety Concerns: If you are unsure about the correct procedures or are working under a high-risk environment.

- Diagnostic Codes: If the machine displays diagnostic codes you’re unfamiliar with, consulting a professional can provide clarity and direction.

Conclusion

Hydraulic problems in the Bobcat T190 can severely impact performance, but they can often be traced back to common issues such as fluid leaks, air in the system, and component failures. Understanding the symptoms, causes, and effective troubleshooting steps can help operators address these issues promptly.

Regular maintenance and attention to detail can significantly reduce the risk of hydraulic problems, ensuring optimal efficiency of your Bobcat T190. For complex matters or ongoing issues, professional assistance is advisable to avoid further complications and maintain the longevity of your equipment.

In summary, operators should familiarize themselves with their machinery, report irregularities promptly, and implement preventive measures to achieve optimal performance while minimizing downtime due to hydraulic complications.Of course! Could you please provide more context or specify what topic or subject you would like me to continue with?