Case Backhoe fuel problems can be a major issue for owners and operators. Fortunately, these issues can be quickly identified and resolved with the help of experienced mechanics and the right tools. In this article, we provide tips and advice on how to diagnose, troubleshoot, and repair fuel problems with your Case Backhoe safely and efficiently.

🚀Recommended article: Case Jx 80 Problems

Diagnosing and Repairing Fuel Problems With Your Case Backhoe

From fuel system contamination to fuel filters clogging up, fuel problems can be a major source of frustration for those who own and operate a Case Backhoe. In this article, we provide important tips and advice on identifying, troubleshooting, and repairing Case Backhoe fuel problems safely and efficiently. We discuss the importance of regular maintenance and inspection, the potential causes of fuel system problems, and the necessary steps for diagnosis and repair. We also review the safety precautions that need to be taken when working with fuel systems and the potential costs associated with repairs. Finally, we provide a troubleshooting table to help you quickly identify and resolve fuel-related issues.

Inspect Fuel Lines

When troubleshooting fuel-related issues in your Case Backhoe, it is important to first inspect the fuel lines for any obstructions, cracks, or other damage. Be sure to look for any debris, dirt, or residue clogging the fuel line and causing a blockage. If you find any blockages, cleaning them out is essential, ensuring that the fuel lines are free from contaminants.

Check Fuel Filters

The next step when addressing fuel-related issues with your Case Backhoe is to check the fuel filters. If the fuel filter is clogged, it can cause the engine to run rough or not start at all. Make sure to replace the fuel filter periodically, as clogged or dirty filters can cause major problems with the engine.

🎯Suggested article: Case Mx100 Problems

Test Fuel Pressure

Testing the fuel pressure is an important step in diagnosing fuel-related problems with your Case Backhoe. Low fuel pressure can cause the engine to sputter or not run. It is essential to check the fuel pressure regularly to ensure it is within the manufacturer's specifications.

Check for Leaks

When troubleshooting fuel-related issues with your Case Backhoe, it is important to check for any leaks in the fuel system. Even a small leak can cause major problems with the engine, and it is essential to address any leaks as soon as possible. Inspect all fuel lines and hoses for any signs of wear or damage.

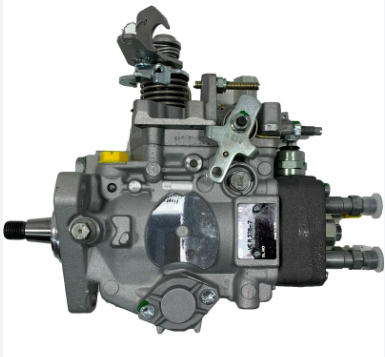

Check the Fuel Pump

The fuel pump is an important component of your Case Backhoe, and it is essential to ensure it works properly. If the fuel pump is faulty or not working correctly, it can cause major issues with the engine. Inspect the fuel pump regularly and replace it if it is not functioning properly.

Key Takeaways for Diagnosing and Repairing Fuel Problems With Your Case Backhoe

- Regularly inspect fuel lines for any obstructions, cracks, or other damage.

- Replace fuel filters periodically to avoid clogging and other issues.

- Test fuel pressure regularly to ensure it is within manufacturer specifications.

- Check for leaks in the fuel system and inspect all fuel lines and hoses.

- Inspect the fuel pump regularly and replace it if it is not functioning properly.

Conclusion: The Benefits of Regular Fuel System Maintenance for Your Case Backhoe

Taking the time to regularly inspect and maintain the fuel system of your Case Backhoe can help save you time and money in the long run. Following the steps outlined above, you can quickly and efficiently identify and address any fuel-related issues promptly and efficiently.

💥See also: Case Ih 485 Problems

Additionally, regular fuel system maintenance can help ensure that your backhoe runs smoothly and efficiently, preventing costly repairs down the line. Taking the time to inspect and maintain the fuel system on your Case Backhoe is an essential part of keeping your machine running at its best.