Case backhoe loaders are renowned for their durability and power, making them an essential tool in construction, landscaping, and agriculture. However, like any heavy machinery, they can present challenges, especially when warning lights illuminate on the dashboard. Understanding the significance of these warning lights is crucial for the safe and efficient operation of your equipment. Ignoring or misinterpreting these signals can lead to decreased performance, costly repairs, and potential safety hazards.

Key Takeaways

- Warning lights serve as indicators of the machine’s health. They can highlight issues ranging from minor to critical.

- Different lights indicate different problems. It’s essential to understand what each light represents to take appropriate action.

- Regular maintenance can prevent many issues. Familiarity with your machine’s symptoms and troubleshooting processes can save time and money.

Problem Description

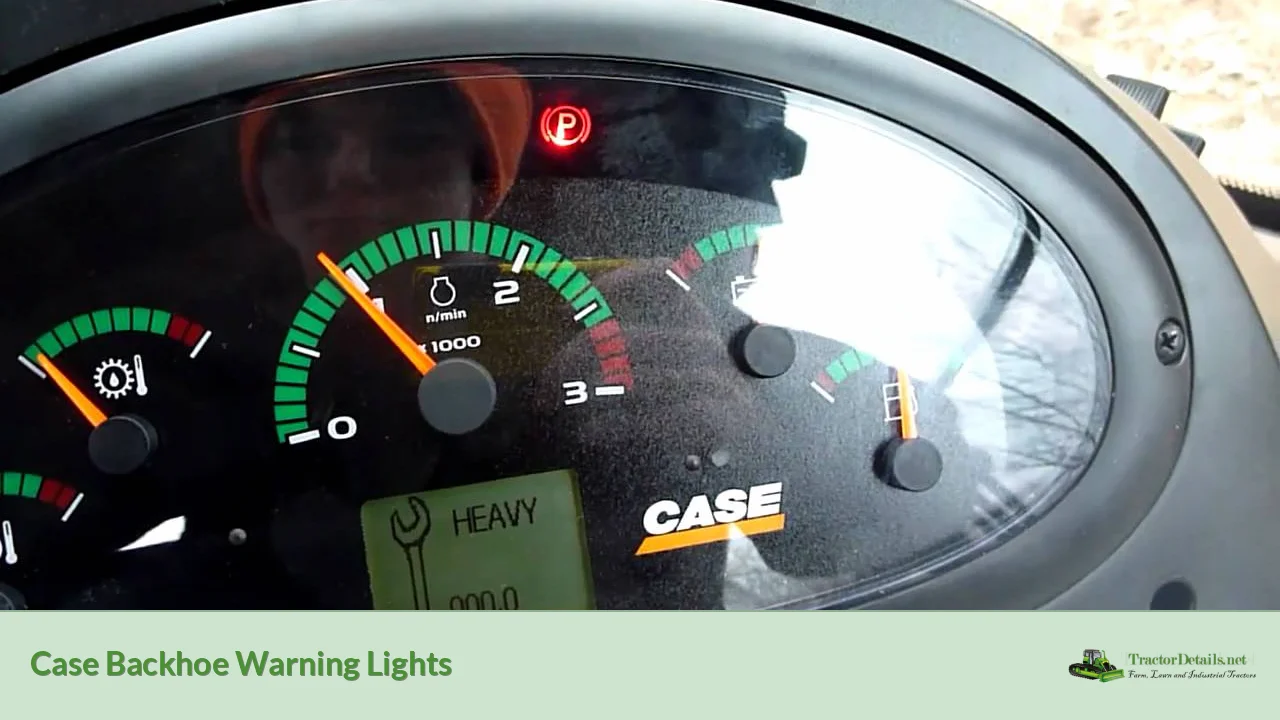

A Case backhoe may display several warning lights, depending on the model. Common models include the Case 580 and Case 590, which feature advanced monitoring systems. Warning lights can signify various problems, including low fluid levels, overheating, battery issues, or hydraulic system failures. Each light could represent both a minor inconvenience or a major failure that requires immediate attention.

Understanding the meaning behind these warning indicators is vital for operators. Failure to address these warnings promptly can result in machine damage, decreased productivity, or even accidents on the job site.

Common Symptoms

Most operational issues in a Case backhoe are accompanied by specific symptoms. Below is a comparison of some common symptoms and their potential causes:

| Symptoms | Possible Causes |

|---|---|

| Warning light illuminates | Low fluid levels, electrical issues, sensor malfunction |

| Engine overheating | Low coolant levels, clogged radiator, faulty thermostat |

| Battery light on | Weak battery, alternator failure, loose connections |

| Hydraulic performance drop | Low hydraulic fluid, damaged hoses, pump failure |

Some of the most prevalent symptoms operators may experience include:

- Illuminated warning lights showing on the dashboard.

- Poor engine performance or unexpected stall.

- Unusual noises from the engine or hydraulic systems.

- Fluid leaks beneath the machine.

- Overheating or excessive engine temperature.

Possible Causes

Understanding the potential causes of warning lights can help operators address issues before they escalate. Typical causes include:

- Low fluid levels: This could involve engine oil, hydraulic fluid, coolant, or transmission fluid, leading to decreased performance or lack of lubrication.

- Electrical issues: Faulty wiring or sensors can trigger warning lights without an actual underlying problem. Malfunctioning alternators or batteries can also result in false signals.

- Hydraulic system problems: Clogged filters, low hydraulic fluid, or damaged components can trigger hydraulic warnings.

- Temperature anomalies: A malfunctioning thermostat or cooling system issues can cause the engine to overheat, activating the warning lights.

Diagnosis Steps

To effectively troubleshoot and fix warning light issues, consider following these steps:

-

Consult the operator's manual: Familiarize yourself with the specific warning light meanings and symptoms corresponding to your model.

-

Check for error codes: Utilize a diagnostic tool compatible with your model (e.g., Case electronic service tool) to retrieve any stored error codes. Common codes for Case backhoes include:

- SPN 130: Engine coolant temperature

- SPN 171: Engine oil pressure

- SPN 79: Hydraulic pressure

-

Inspect fluid levels: Start with checking oil, coolant, and hydraulic fluid levels. Refill any low levels as needed.

-

Examine electrical connections: Look for loose, damaged, or corroded wires leading to warning sensors.

-

Evaluate the hydraulic system: Check filters, hoses, and the hydraulic pump for any visible signs of damage or wear.

-

Test for overheating: Ensure the radiator is not clogged and that the cooling system is functioning correctly.

Troubleshooting and Repair Procedures

Once you have diagnosed the issue, follow these steps to troubleshoot and repair the problem effectively:

-

Fluid Levels and Quality:

- Inspect and top up engine oil, coolant, and hydraulic fluid.

- Replace fluids if they appear dirty or contaminated.

-

Electrical Repairs:

- Repair or replace any damaged wires.

- Test the battery and alternator with a multimeter to ensure they meet manufacturer specifications (usually 12 to 14 volts).

-

Hydraulic System Maintenance:

- Replace clogged hydraulic filters.

- Address any leaks from hoses and fittings.

- Consult the service manual for pump replacement procedures if needed.

-

Cooling System Service:

- Flush and refill the cooling system if necessary.

- Replace the thermostat if overheating persists after addressing coolant levels.

-

Regular Maintenance Checks:

- Perform regular scheduled maintenance to ensure all systems are functioning correctly to prevent future warning light issues.

Estimated Repair Costs

Repair costs for warning light issues in Case backhoes can vary significantly based on the problem identified. Below are typical cost ranges:

- Fluid changes: $100-$300

- Battery replacement: $150-$250

- Electrical repairs: $80-$150 per hour of labor, depending on the complexity.

- Hydraulic repairs: $200-$1,500 for pump or hose replacements.

- Cooling system repairs: $300-$1,000, depending on the extent of the damage or component replacement.

Prevention Tips

Preventative maintenance is key to keeping your Case backhoe in optimal condition. Here are some tips:

- Adhere to a regular maintenance schedule: Follow the manufacturer's guidelines for servicing the backhoe.

- Conduct daily inspections: Check fluid levels, look for leaks, and test all systems before operation.

- Keep the machine clean: Regular cleaning helps prevent dirt and debris from causing mechanical failures.

- Train operators properly: Ensure that anyone who operates the backhoe is knowledgeable about the machine’s controls and warning systems.

When to Seek Professional Help

While DIY troubleshooting can resolve many issues, some situations merit professional assistance. Consider contacting a professional mechanic or service technician if:

- The warning light remains lit after addressing potential causes.

- You are uncomfortable performing electrical or hydraulic repairs.

- Specific tools or diagnostic equipment are necessary and you lack access to them.

- Significant symptoms are present, such as unusual sounds or drastic performance drops.

Conclusion

Understanding and responding to the warning lights on your Case backhoe is vital for maintaining performance and avoiding costly damage. By comprehensively diagnosing any warning indicators, troubleshooting efficiently, and performing regular maintenance, operators can ensure their machines remain reliable and effective.

In summary, keep the following points in mind:

- Always pay attention to warning lights; they signal the health of your machine.

- Regular maintenance can hasten troubleshooting and prevent minor issues from becoming major repairs.

- Ensure all operators are trained in recognizing and addressing potential problems to enhance safety and efficiency across job sites.

Investing time in understanding and maintaining your Case backhoe not only prolongs the life of the machinery but also boosts productivity on every job.Of course! What would you like to continue with? If you have a topic in mind, a question, or something specific you'd like to discuss, feel free to share!