Caterpillar equipment is renowned for its durability and versatility in heavy construction and various industrial applications. However, owners often face difficulties when troubleshooting issues related to their equipment, especially concerning year identification by serial numbers. Knowing how to decode a Caterpillar serial number can significantly aid in identifying necessary parts, technical manuals, and service history, thus enhancing the efficiency of any maintenance or repair task.

Key Takeaways

- Caterpillar serial numbers serve as vital tools for identifying the manufacture year and model of heavy machinery.

- Understanding common symptoms of issues tied to specific serial numbers can help streamline repairs.

- Accurate diagnosis can save time and money by preventing misdirected efforts in troubleshooting.

- Regular maintenance and timely repairs are essential for sustaining equipment performance.

| Symptoms | Possible Causes |

|---|---|

| Lack of power | Clogged fuel filter, low fuel pressure |

| Unusual sounds from engine | Worn bearings, loose components |

| Warning lights on the dashboard | Electrical faults, sensor issues |

| Difficulty starting | Battery issues, starter malfunction |

| Overheating | Coolant leaks, faulty thermostat |

Problem Description

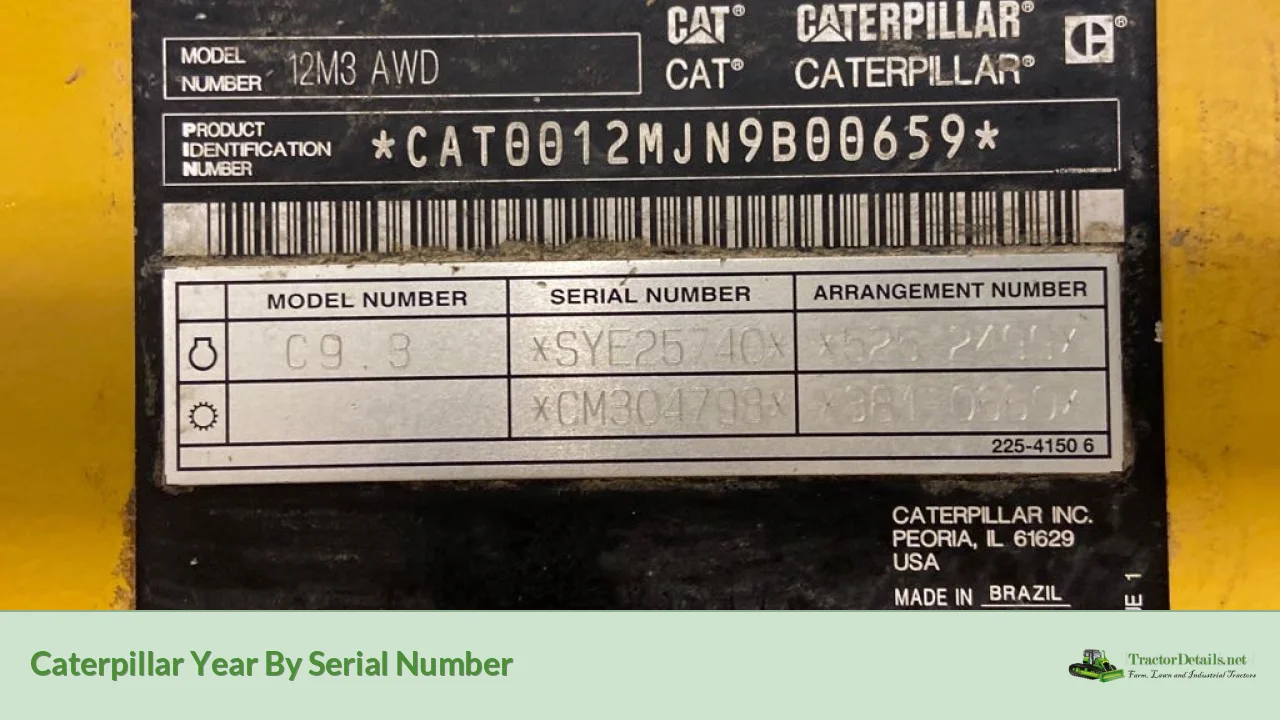

Caterpillar machinery may exhibit various issues that necessitate checking the serial number. Each serial number contains vital information concerning the machine's specific model, manufacture year, and production plant. This information is crucial for obtaining the correct replacement parts and understanding the model's nuances during troubleshooting.

For example, Caterpillar serial numbers are typically alphanumeric, consisting of 6-10 characters, which can vary between different types of equipment, including excavators, bulldozers, and generators. Discrepancies in serial numbers can lead to incorrect parts orders, misdiagnosis of problems, or improper repair procedures. Therefore, understanding the structure and significance of Caterpillar year by serial number is essential for all operators and technicians.

Common Symptoms

Certain symptoms often indicate underlying problems with machinery that can be traced back to specific serial numbers. Identifying these symptoms early can prevent more extensive damage and costly repairs.

- Lack of Power: The machinery fails to perform at expected levels.

- Unusual Sounds: Grinding, whining, or knocking noises indicate mechanical failure.

- Warning Lights: Alerts on the dashboard signal specific issues, such as low oil pressure or overheating.

- Difficulty Starting: This may indicate a battery issue or electrical failure.

- Overheating: High engine temperature could result from coolant failure, leading to serious engine damage.

Possible Causes

Understanding what could cause these symptoms is crucial for diagnosing issues effectively.

- Lack of Power:

- Clogged fuel filter

- Low fuel pressure

- Malfunctioning turbocharger

- Unusual Sounds:

- Worn bearings could indicate extensive engine wear.

- Loose components can lead to mechanical failures.

- Warning Lights:

- Electrical faults may originate from faulty wiring.

- Sensor issues often trigger warning signals.

- Difficulty Starting:

- Faulty batteries can fail to deliver adequate current.

- Starter motor malfunctions prevent engine cranking.

- Overheating:

- Coolant leaks can lead to engine failure.

- A faulty thermostat may prevent the coolant from circulating effectively.

Diagnosis Steps

Diagnosing a problem in Caterpillar machinery involves a structured approach, particularly emphasizing the serial number for accuracy in identifying components.

- Identify the Serial Number:

- Locate the serial number tag, usually on the body or frame of the machine, to determine model and year.

- Consult Technical Manuals:

- Use the identified serial number to access relevant technical documentation.

- Check for Error Codes:

- Utilize diagnostic tools to read any stored errors in the machine’s electronics.

- Visual Inspection:

- Look for obvious leaks, cracks, or worn hoses and electrical components.

- Conduct Performance Tests:

- Evaluate how the equipment performs under load conditions to replicate the problem.

Troubleshooting and Repair Procedures

Based on diagnosed issues, the following troubleshooting and repair procedures are recommended.

Lack of Power

- Check Fuel System:

- Replace clogged filters.

- Inspect the fuel pump for adequate pressure.

- Examine Air Filters:

- Clean or replace air filters to ensure proper airflow.

Unusual Sounds

- Inspect Engine Components:

- Perform a thorough check of bearings and moving parts.

- Tighten loose components to prevent further damage.

Warning Lights

- Diagnostic Tools:

- Use OBD-II or CAT-specific diagnostic tools to check error codes.

- Sensor Inspection:

- Replace faulty sensors or rectifying wiring issues.

Difficulty Starting

- Battery Check:

- Test the battery voltage; replace if necessary.

- Starter Assessment:

- Inspect the starter motor and the solenoid for functionality.

Overheating

- Check Coolant Levels:

- Refill or replace coolant and inspect for leaks.

- Thermostat Replacement:

- Test the thermostat for proper operation and replace if faulty.

These repair and troubleshooting procedures often require specific knowledge and expertise particularly related to Caterpillar machinery.

Estimated Repair Costs

The costs associated with repairs can vary dramatically based on the specific issue and whether it is handled by an independent technician or a Caterpillar dealer.

- Basic Maintenance (oil change, filters replacement): $200 - $500

- Minor Repairs (fuel system flush): $300 - $800

- Major Repairs (engine rebuild): $2,000 - $10,000

- Diagnostic Fees (if professional assistance is needed): $100 - $150 per hour

Always get multiple quotes and ensure that the repair shop specializes in Caterpillar machinery.

Prevention Tips

To avoid common issues and enhance the lifespan of Caterpillar machinery, consider the following preventive measures:

- Regular Maintenance: Stick to a strict service schedule recommended by Caterpillar.

- Use Quality Parts: Utilize OEM (Original Equipment Manufacturer) parts for replacements.

- Conduct Daily Checks: Assess the machinery for any leaks or irregularities before operation.

- Keep Machinery Clean: Ensure that the exterior is free of dirt and debris, particularly around the engine and air-intake areas.

- Train Operators: Ensure that all machine operators are adequately trained in proper usage and safety procedures.

When to Seek Professional Help

Certain situations warrant professional assistance, especially when:

- Complex Electrical Issues Arise: If electrical diagnosis exceeds basic troubleshooting.

- Major Engine Malfunctions Occur: When noises or performance issues indicate potential catastrophic failure.

- Lack of Tools or Experience: If you do not have the appropriate diagnostic tools, it’s best to consult a professional.

- Persistent Problems: If repairs made do not resolve the issues, a professional second opinion can be critical.

Conclusion

Understanding Caterpillar year by serial number is integral for effective troubleshooting and maintenance of heavy machinery. By recognizing symptoms, diagnosing potential causes, and applying correct repair procedures, operators can significantly reduce downtime and repair costs.

Regular maintenance and use of proper parts are fundamental for preserving the performance and longevity of your equipment. While DIY solutions can often resolve minor issues, seeking professional help for complex problems ensures your machinery remains in peak condition.

Use this guide to help navigate the challenges associated with Caterpillar machinery and keep your equipment performing at its best. Remember, informed operators are successful operators!It seems like your message might be incomplete. Could you please provide more context or specify what you would like to continue discussing? I'm here to help!