Understanding the warning lights on a Case skid steer is essential for safe and efficient operation. These warning lights serve as indicators of potential issues within the hydraulic system, engine performance, and overall machine health. Recognizing what each light signifies can help operators take timely actions to prevent further damage and ensure the longevity of their equipment.

The hydraulic oil warning light is particularly crucial, as it often indicates low hydraulic fluid levels or problems within the hydraulic system. Ignoring these warnings can lead to severe mechanical failures, increased repair costs, and even safety hazards. This article will delve into the various warning lights associated with Case skid steers, their meanings, troubleshooting steps, and best practices for maintenance.

| Warning Light | Meaning |

|---|---|

| Hydraulic System Light | Indicates low hydraulic fluid levels or system faults. |

| Engine Warning Light | Signals engine malfunctions or overheating issues. |

| Oil Pressure Light | Alerts low oil pressure that could damage engine components. |

Types of Warning Lights

The warning lights on Case skid steers can be categorized into several types, each serving a specific purpose. Understanding these categories is vital for operators to respond appropriately.

- Hydraulic System Lights: These lights illuminate when there is a significant drop in hydraulic fluid levels or when a fault occurs in the hydraulic system. It is crucial to address these warnings immediately to avoid severe damage to the hydraulic components.

- Engine Warning Lights: These lights indicate problems related to the engine, such as overheating, low coolant levels, or emission control issues. Operators should pay close attention to these signals as they can affect overall machine performance.

- Oil Pressure Lights: This light warns operators of low oil pressure, which can lead to excessive wear on engine parts or complete engine failure. Immediate action is necessary when this light activates.

Recognizing these categories helps operators prioritize their responses and maintain their equipment effectively.

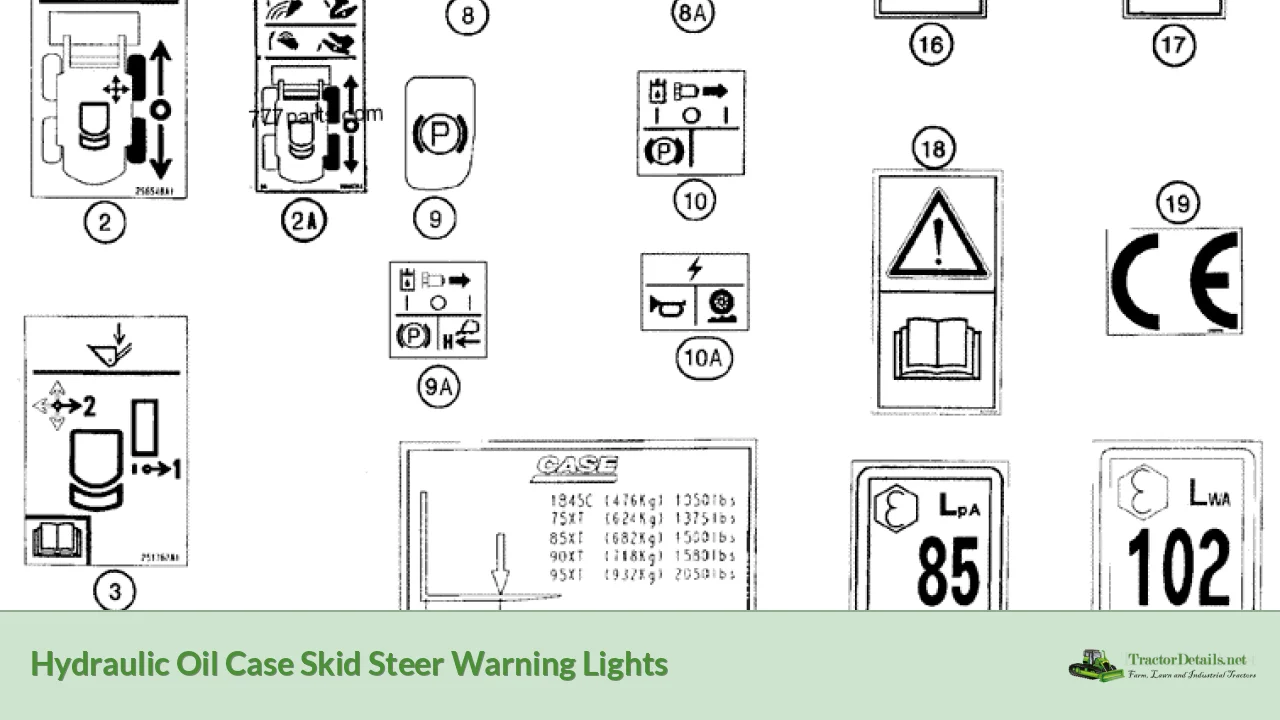

Common Case Skid Steer Warning Lights and Their Meanings

Several standard warning lights are common across various models of Case skid steers. Familiarity with these indicators can enhance an operator's ability to manage potential issues effectively.

- Hydraulic Warning Light: Typically represented by a gear or oil drop icon, this light indicates problems with hydraulic fluid levels or system faults. If illuminated, operators should check fluid levels and inspect for leaks.

- Engine Light: Often depicted as an engine block icon, this light signals that the engine may be experiencing issues such as high temperature or malfunctioning components. A blinking light usually indicates a severe problem requiring immediate attention.

- Oil Pressure Light: Shown as an oil can or gauge icon, this light warns of dangerously low oil pressure. Ignoring this warning could lead to significant engine damage.

Understanding what each light represents allows operators to take swift action, reducing the risk of costly repairs and downtime.

Potential Issues Indicated by Case Skid Steer Warning Lights

Each warning light corresponds to specific potential issues within the skid steer. Identifying these problems early can prevent more serious complications down the line.

- Hydraulic System Issues: An illuminated hydraulic warning light may indicate low fluid levels, leaks in the system, or excessive pressure buildup. Operators should check fluid levels immediately and inspect hoses and connections for leaks.

- Engine Problems: The engine warning light may point toward overheating due to low coolant levels or other mechanical failures such as misfires. Regularly checking coolant levels and monitoring engine performance can help mitigate these risks.

- Oil Pressure Concerns: When the oil pressure light is on, it suggests that oil pressure is critically low. Operators must check oil levels promptly; prolonged low pressure can severely damage internal engine components.

Awareness of these potential issues allows operators to maintain their equipment proactively and avoid unexpected breakdowns.

Troubleshooting Case Skid Steer Warning Lights

Effective troubleshooting is essential for managing warning lights on Case skid steers. A systematic approach can help identify the source of the issue and determine appropriate corrective actions.

When faced with an illuminated engine warning light, operators should:

- Listen for unusual noises from the engine.

- Check performance metrics such as speed and power.

- Consult the operator’s manual for guidance on specific error codes or warnings.

For a hydraulic system warning light, immediate steps include:

- Inspecting hydraulic fluid levels.

- Checking for visible leaks around hoses and fittings.

- Ensuring that all connections are secure and free from damage.

In case of an oil pressure warning, operators should:

- Verify that oil levels are adequate.

- Inspect for leaks in the oil system.

- Consider scheduling professional maintenance if issues persist after checks.

By following these troubleshooting steps, operators can address warning lights effectively and maintain operational efficiency.

Addressing Potential Warning Light Problems

Timely intervention is critical when dealing with warning lights on skid steers. Here are some practical suggestions for addressing common issues:

When the engine warning light activates:

- Conduct a thorough inspection of all engine fluids including coolant and oil.

- Look out for any loose connections or damaged components that could affect performance.

For a hydraulic system warning light:

- Immediately check hydraulic fluid levels; if they are low, refill with the appropriate type of fluid.

- Examine hoses for any signs of wear or leaks that could compromise system integrity.

If faced with an oil pressure warning, it’s crucial to:

- Stop operations immediately to prevent further damage.

- Check oil levels and add oil if necessary; if pressure remains low after refilling, consult a professional mechanic.

By being proactive about these warnings, operators can significantly extend the life of their equipment while ensuring safety during operations.

What Experts Say

Industry professionals emphasize that understanding and responding appropriately to skid steer warning lights is vital for preventing machine failure. Many mechanics note that one of the most common issues arises from the oil pressure light; when illuminated, it often indicates critically low oil levels that could cause irreversible damage if not addressed immediately.

Experts recommend regular inspections of both coolant levels and engine temperatures as preventative measures against triggering the engine warning light. Additionally, they highlight that hydraulic system faults frequently correlate with alerts from hydraulic system lights.

Consulting comprehensive manuals provided by Case can assist in interpreting various lights accurately; however, persistent warnings should always prompt professional diagnostics to ensure safety and reliability in operations.

FAQs About Hydraulic Oil Case Skid Steer Warning Lights

- What does it mean when my hydraulic oil light comes on?

This indicates low hydraulic fluid levels or a fault in the hydraulic system. - How do I troubleshoot my skid steer if a warning light is illuminated?

Check fluid levels immediately and inspect for any visible leaks or mechanical issues. - What should I do if my engine warning light turns on?

Inspect all fluids and listen for unusual noises; consult your operator’s manual if problems persist. - Is it safe to ignore a flashing oil pressure light?

No, you should stop operations immediately as ignoring this can lead to severe engine damage. - How often should I check my skid steer’s fluids?

Regular checks before operation are recommended to ensure optimal performance and safety.

By understanding these aspects of hydraulic oil case skid steer warning lights, operators can enhance their operational safety while ensuring their machinery remains in optimal condition.