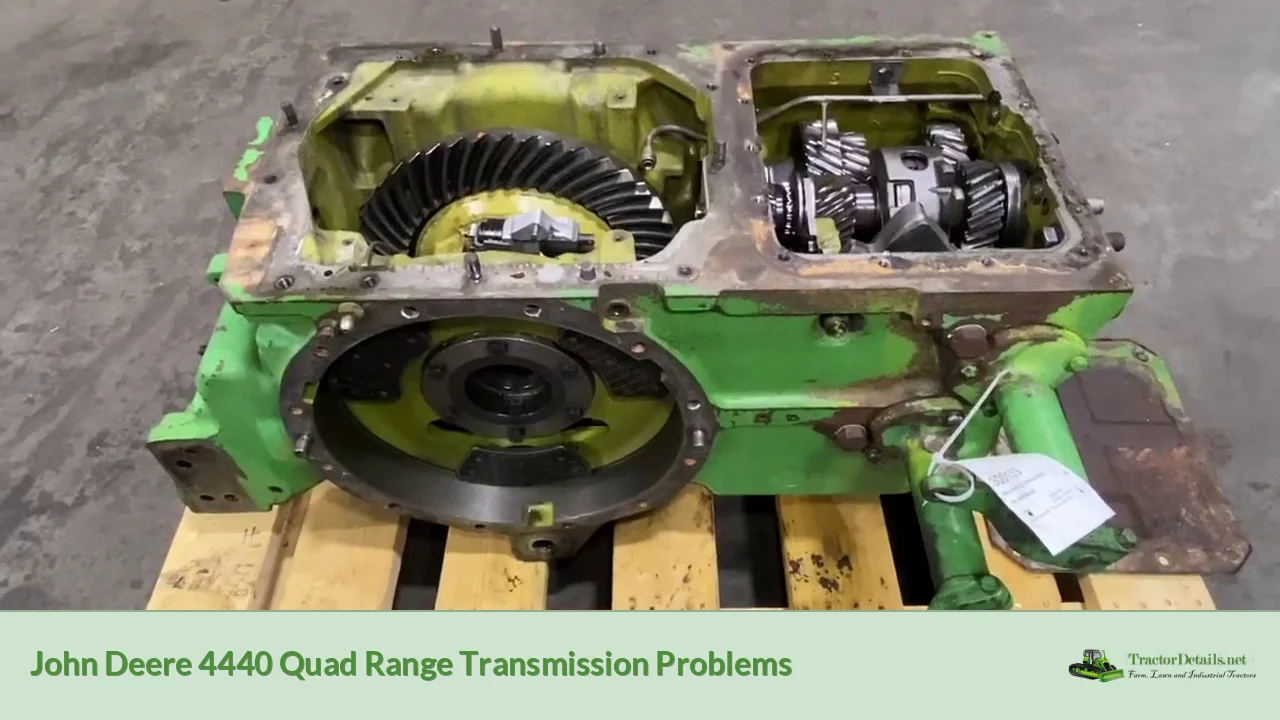

John Deere's 4440 tractor is equipped with a robust Quad Range transmission that provides high versatility and efficiency for various farming tasks. However, as with any heavy machinery, users may encounter specific transmission-related issues over time. Identifying, diagnosing, and resolving these problems promptly is essential for maintaining optimal performance and longevity. This comprehensive guide will delve into the common problems associated with the John Deere 4440 Quad Range transmission, highlighting symptoms, causes, diagnosis steps, and repair procedures.

Key Takeaways

- The John Deere 4440's Quad Range transmission is known for reliability, but it is not immune to problems.

- Common symptoms include unusual noises, difficulty shifting gears, and erratic performance.

- Regular maintenance and awareness of potential issues can prevent major breakdowns.

- Understanding the specific problems and having a troubleshooting plan can save time and money.

| Symptoms | Possible Causes |

|---|---|

| Difficulty in shifting | Low transmission fluid level |

| Overheating | Clogged filters |

| Unusual noises (grinding) | Worn gears or failures in hydraulic system |

| Erratic performance | Faulty electronic components |

Problem Description

The John Deere 4440 Quad Range transmission system is a highly regarded transmission due to its four-speed ranges (Low, Medium, High, and Reverse) that cater to varied operational needs. However, it may suffer from several issues ranging from minor to severe. Problems can manifest in different ways, leading to performance issues that impede agricultural tasks. Typical complaints include unusual grinding noises during operation, challenges in shifting between gears, and overheating during extended use.

Common Symptoms

Being aware of the symptoms associated with transmission issues can help you take timely action. Owners should monitor for the following signs:

- Difficulty shifting gears: You may notice resistance when attempting to change gears, which could indicate low fluid levels or wear in the shift linkage.

- Clunking or grinding noises: Sounds that suggest mechanical failure, such as grinding or clunking, are indicative of worn gears or bearings that must be addressed quickly.

- Erratic or slipping performance: If the tractor hesitates or slips out of gear unexpectedly, it might mean internal components are wearing out or failing.

- Overheating: Excessive heat can be a sign of inadequate lubrication or hydraulic issues, leading to potential damage if not resolved.

- Fluid leaks: Any visible leaks under the tractor should be addressed immediately, as they may indicate seal failures or hose issues.

Possible Causes

Understanding the root causes of these symptoms is essential for effective troubleshooting. Some common factors contributing to transmission problems include:

- Low transmission fluid levels: This may arise from leaks or inadequate maintenance, resulting in insufficient lubrication.

- Clogged filters: Over time, filters can become blocked, restricting fluid flow and causing overheating and erratic behavior.

- Worn or damaged components: Gear wear, hydraulic pump failures, or problems with linkages can directly impact gear shifting and overall performance.

- Faulty electronic components: Systems relying on sensors or wiring for operation may experience failures that affect communication or functionality.

Diagnosis Steps

To address transmission problems effectively, follow these diagnostic steps:

- Check fluid levels: Ensure that the transmission fluid is at the proper level. Refer to the operator's manual for specifications on how to check fluid levels correctly.

- Inspect for leaks: Look under the tractor and around the transmission for visible fluid leaks, as these can indicate sealing issues.

- Examine filters: Remove and check the condition of the transmission filters for blockages; replace if necessary.

- Listen for noises: Get a feel for where clunking or grinding noises are coming from when the tractor is in operation to isolate problem areas.

- Test electronic components: If equipped, check wiring and sensors for faults. Use a multimeter to ensure there are no issues with electrical connections.

Troubleshooting and Repair Procedures

If diagnosis identifies an issue, follow these procedures to troubleshoot and repair the transmission:

-

Fluid and filter replacement:

- Drain the old transmission fluid and replace it with the manufacturer's recommended fluid.

- Change the filters to ensure proper fluid flow.

-

Adjustments:

- Ensure the shift linkage is properly adjusted. Misalignment can cause difficulty in changing gears.

-

Addressing leaks:

- For any identified leaks, replace the faulty seals, gaskets, or hoses. Be sure to clean surrounding areas to prevent contamination from old fluid.

-

Component replacement:

- For severe wear or damage, you might need to replace gears, bearings, or hydraulic pumps. This may require disassembling the transmission, so following the service manual for your specific model is crucial.

-

Testing after repairs:

- After completing repairs, run the tractor to test for any remaining issues. Pay attention to shifting performance and listen for unusual noises.

Estimated Repair Costs

Costs for repairing transmission issues can vary widely based on the specific problem and labor rates. Here's a rough breakdown:

- Fluid change and filter replacement: $150 to $400

- Professional diagnosis: $50 to $150 (typically an hourly rate)

- Shift linkage adjustment: $50 to $200

- Gear or component replacement: $500 to $2,500 (depending on parts needed)

- Complete transmission overhaul: Can range from $2,000 to over $5,000, depending on the extent of the damage and local labor rates.

Prevention Tips

To avoid transmission problems, maintain your John Deere 4440 with the following best practices:

- Regular maintenance: Follow the manufacturer's maintenance schedule for fluid changes and filter replacements.

- Monitor fluid levels: Regularly check transmission fluid levels to ensure they stay topped off.

- Keep it clean: Maintain cleanliness around the transmission to prevent dirt and debris from entering the system.

- Avoid overload: Ensure you're operating within the tractor's rated capacity to reduce stress on the transmission.

When to Seek Professional Help

While many issues can be addressed by experienced DIY enthusiasts, there are situations where professional assistance is necessary:

- Complex repairs: If extensive disassembly or specialized tools are required, a qualified mechanic will ensure proper techniques are employed.

- Repeated issues: If the same problems recur even after your repairs, it may indicate deeper issues requiring a professional diagnosis.

- Electrical problems: Issues related to electronic components can be intricate and often need specialized diagnostic tools.

Conclusion

In summary, the John Deere 4440 Quad Range transmission is a reliable system that may encounter various issues over time. Key symptoms to watch for include difficulty in shifting, unusual noises, erratic performance, and overheating. By following outlined diagnostic steps and troubleshooting methods, owners can effectively address many common problems. Regular maintenance plays a crucial role in preventing future issues.

When faced with complex issues, do not hesitate to contact a professional to ensure your tractor runs smoothly and efficiently for years to come. Taking proactive measures will not only enhance your machine’s performance but also save you time and money in the long run.Of course! How can I assist you further? If you have a specific topic, question, or context in mind, please let me know!