The John Deere 7800 equipped with Power Quad Transmission is a robust machine appreciated for its reliability and efficiency on the farm. However, just like any complex machinery, it can encounter issues that may affect its performance, and the Power Quad Transmission is no exception. Addressing these problems early on is crucial to prevent extensive damage and ensure smooth operations. In this article, we will discuss the common problems associated with the John Deere 7800 Power Quad Transmission, their symptoms, causes, troubleshooting steps, repair options, and preventative measures.

Key Takeaways

- Power Quad Transmission problems can lead to decreased performance and unexpected failures in John Deere 7800 vehicles.

- Common symptoms include erratic shifting, slipping gears, and unusual noise.

- A systematic approach to diagnosis and troubleshooting can resolve many issues.

- Regular maintenance and awareness of symptoms can help prevent major failures.

| Symptoms | Possible Causes |

|---|---|

| Erratic or hard shifting | Worn synchronizers, low hydraulic fluid |

| Gear slipping | Contaminated fluid, worn clutches |

| Unusual noises | Gear wear, faulty bearings |

| Warning lights or codes | Electrical issue, sensor failure |

Problem Description

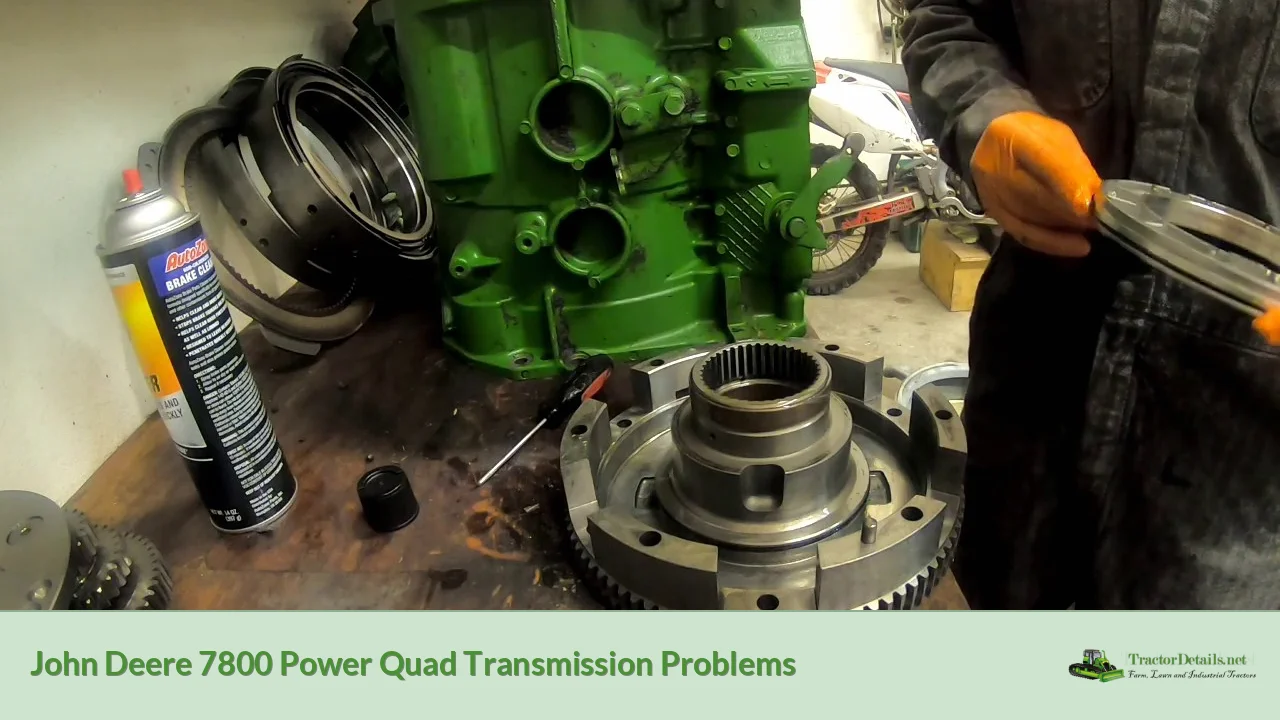

The John Deere 7800 Power Quad Transmission is designed to offer seamless shifting, but various issues can arise due to either mechanical failures or maintenance lapses. Typical problems include difficulty in transitioning between gears, unexpected gear slippage, or abnormal noises during operation. Additionally, the system's hydraulic components can potentially malfunction, leading to inefficient operation. Identifying these problems early can save time and money, prolonging the lifespan of the machinery.

Common Symptoms

When dealing with Power Quad Transmission issues, operators may notice the following symptoms:

- Erratic or hard shifting: This may manifest as difficulty engaging the transmission into gear or rough transitions.

- Gear slipping: The tractor may unexpectedly change gears or lose power during operation.

- Unusual noises: Grinding or whining sounds while shifting may indicate mechanical issues or worn components.

- Warning lights or error codes: Such as the fault code 2651, which indicates a gear-related issue.

Possible Causes

Numerous factors can contribute to Power Quad Transmission problems in the John Deere 7800. Here are some common causes:

- Low or contaminated hydraulic fluid: Insufficient hydraulic fluid can lead to inadequate pressure for shifting.

- Worn synchronizers: These components are essential for smooth gear transitions and can wear out over time.

- Damaged clutch packs: Worn or damaged clutches can cause slipping and erratic behavior.

- Faulty sensors or electrical issues: The Power Quad Transmission relies on a series of sensors that can fail, sending incorrect signals to the transmission control unit.

Diagnosis Steps

Diagnosing the problem is critical before jumping to repairs. Follow these steps for an effective diagnosis:

-

Check the hydraulic fluid level:

- Inspect for any leaks.

- Consider performing a fluid analysis to check for contamination.

-

Retrieve error codes:

- Use a diagnostic scanner compatible with John Deere equipment.

- Look for any active or historical fault codes that can guide further investigation.

-

Inspect the transmission:

- Physically check the transmission for any visible damage or wear.

- Examine the condition of the wiring and sensors.

-

Test the shifting mechanism:

- Engage gears manually if possible.

- Listen for unusual noises or feedback from the shift lever.

-

Evaluate the clutch operation:

- Check engagement firmness and responsiveness.

- Note if the clutch is slipping during working conditions.

Troubleshooting and Repair Procedures

Once the diagnosis is complete, the following troubleshooting and repair procedures can be undertaken:

Basic Repairs

-

Fluid Change:

- If low or contaminated hydraulic fluid is identified, perform a fluid change using the manufacturer-recommended fluid.

-

Replace Worn Parts:

- Synchronizers and clutch packs that show signs of wear should be replaced. Consult the service manual for detailed instructions.

Advanced Repairs

-

Repair or Replace Sensors:

- If diagnostics indicate faulty sensors, replace them according to specifications provided in service guides.

-

Check Electrical Connections:

- Inspect harnesses and connectors for corrosion or damage. Repair or replace as necessary.

-

Transmission Overhaul:

- In cases of severe mechanical failure, a complete transmission overhaul may be necessary. This is a labor-intensive task that may require professional assistance.

Estimated Repair Costs

Repair costs can vary widely based on the severity of the issue and whether you opt for DIY repairs or professional assistance. Here’s a rough estimate:

- Fluid Change: $100 - $250 (including new fluid and filters)

- Clutch Packs Replacement: $600 - $1,200

- Synchronizer Replacement: $500 - $800

- Sensor Replacement: $200 - $400 each

- Full Transmission Overhaul: $3,000 - $5,000

Note: Prices can vary based on regional labor costs and parts availability. Always consult with a local dealer or repair shop for a precise estimate.

Prevention Tips

To prevent Power Quad Transmission problems, consider the following preventative measures:

- Regular Maintenance: Follow a strict maintenance schedule, including regular fluid changes and inspections.

- Monitor Fluid Conditions: Check the hydraulic fluid regularly for contamination or abnormal wear.

- Address Symptoms Promptly: Pay attention to any signs of transmission issues and address them as soon as possible to prevent further damage.

- Use Quality Parts: When replacing components, always use genuine John Deere parts to ensure compatibility and reliability.

When to Seek Professional Help

While many small repairs can be carried out by diligent DIY enthusiasts, there are times when seeking professional help is advisable:

- Complex Problems: If the issue involves a complete transmission overhaul or intricate electrical diagnostics, entrust the job to a trained technician.

- Lack of Tools/Experience: If you feel unequipped to handle certain repairs, particularly those requiring specialized tools, consulting professionals can save you time and potentially avoid costly mistakes.

- Persistent Issues: If you have addressed apparent issues but problems persist, a thorough inspection from a professional may be necessary to uncover underlying faults.

Conclusion

In summary, the John Deere 7800 Power Quad Transmission is a complex and durable system that, like any machinery, can face challenges. Recognizing symptoms early and taking the right diagnostic and troubleshooting steps can mitigate more serious problems. By adhering to a regular maintenance schedule and being aware of potential issues, owners can maximize the lifespan and efficiency of their equipment. For those who are less experienced, timely consultations with certified professionals are recommended to ensure optimal performance and reliable operation of this valuable farming machinery. Always remember, a well-maintained transmission translates into a more productive workday on the field.It seems like you would like to continue a conversation or a topic, but I need more context to help you effectively. Could you please provide more details or clarify what you would like to continue discussing?