Excavators are essential heavy machinery often used in construction and earthmoving projects. One brand that stands out in this category is John Deere, known for its reliability and efficiency. However, like all machinery, John Deere excavators can experience issues, particularly related to warning lights. These warning lights can indicate various problems, and understanding their significance is crucial for maintaining the machine's health and preventing costly repairs.

Key Takeaways

- John Deere excavator warning lights are indicators of potential issues that require attention.

- Common symptoms may include visible warning lights, irregular machine performance, and varied sound alerts.

- Possible causes can range from low fluid levels to sensor malfunctions.

- Regular diagnostic steps can help identify the root cause of the warning lights.

- Troubleshooting and repairs may involve simple checks or complex technical interventions.

- Preventive maintenance is key to avoiding warning light issues in the future.

Problem Description

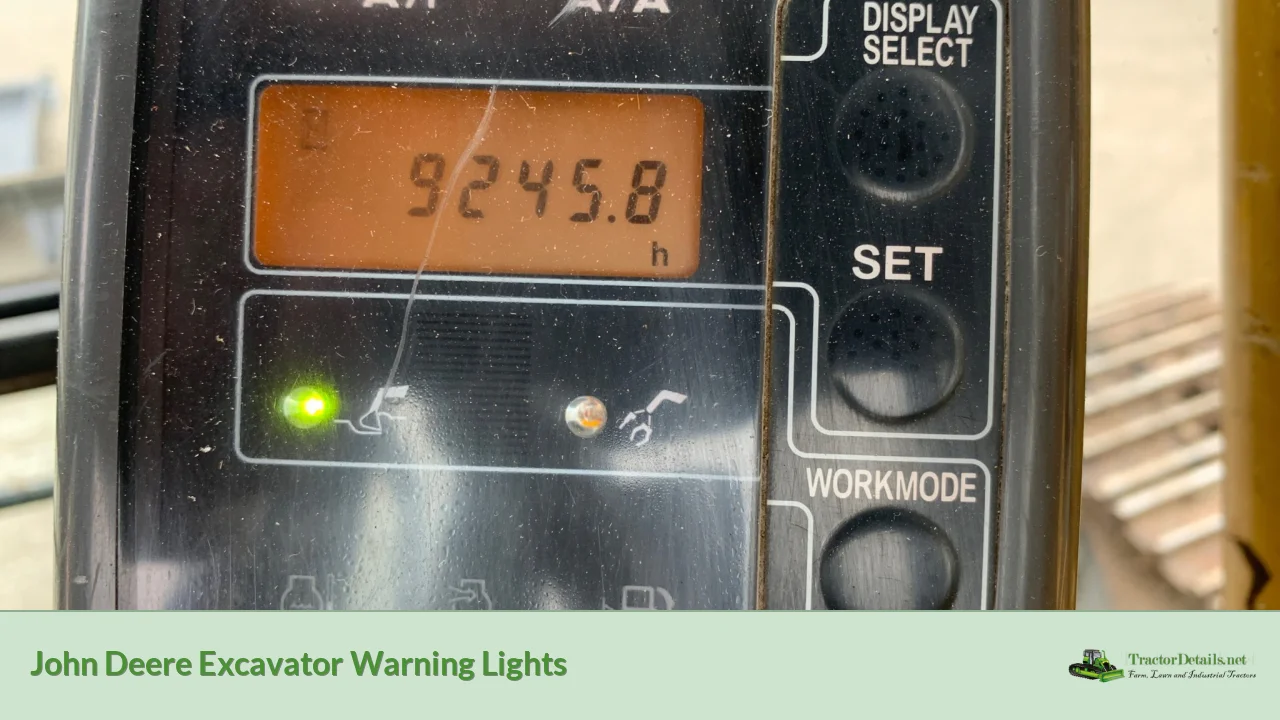

When operating a John Deere excavator, various warning lights may illuminate on the dashboard. These lights serve as safety measures to alert the operator of specific faults, thus preventing further damage to the machinery. Understanding the meaning behind each warning light is crucial for maintaining efficient operations.

Typical warning lights can include:

- Engine Oil Pressure

- Coolant Temperature

- Hydraulic Pressure

- Battery Charge

- Transmission Fluid Temperature

Operating machinery with illuminated warning lights can lead to significant breakdowns or complete machine failure, so immediate attention is needed.

Common Symptoms

When a John Deere excavator has warning lights illuminated, the operator may notice several symptoms, including:

| Symptoms | Possible Causes |

|---|---|

| Warning lights illuminated | Low fluid levels |

| Engine overheating | Faulty temperature sensors |

| Erratic machine behavior | Hydraulic system issues |

| Unusual noises | Mechanical failures |

| Decreased operational power | Low battery charge or failure |

Other observable symptoms may include:

- Sluggish movement of the boom or arm.

- Vibrations or rattling noises during operation.

- Abnormal fuel consumption rates.

- Frequent machine shutdowns.

Possible Causes

The underlying causes for warning lights on a John Deere excavator can vary widely. Here are some of the most common possibilities:

- Fluid Levels: Low oil, coolant, or hydraulic fluid levels can trigger warning lights.

- Sensor Failures: Malfunctioning sensors can send incorrect readings to the control unit.

- Electrical Issues: Problems with wiring, connections, or battery can impact sensor reliability.

- Mechanical Failures: Components within the hydraulic system or engine malfunctioning can cause warning signals.

- Overheating: High engine temperatures due to poor coolant circulation or blockage can trigger alerts.

Regular maintenance and awareness of the machine's current state can help minimize these issues.

Diagnosis Steps

To diagnose the cause of the illuminated warning lights, follow these steps:

- Check the Owner’s Manual: Each warning light has a specific meaning detailed in the manual.

- Visual Inspection: Conduct a visual inspection of the fluid levels, cables, and connections.

- Use Diagnostic Tools: Use a multimeter or John Deere’s Service Advisor to read error codes and diagnostics.

- Monitor Performance: Pay attention to any changes in machine operation, unusual noises, or vibrations.

- Record Error Codes: Write down any error codes and refer to John Deere’s documentation for explanations.

Troubleshooting and Repair Procedures

Here are some troubleshooting and repair procedures that can help address warning lights on a John Deere excavator:

Fluid Level Checks

- Oil Levels: Ensure that engine oil and hydraulic fluid are at appropriate levels. Top off if low.

- Coolant Levels: Verify that coolant is filled to the recommended levels to prevent overheating.

Electrical System

- Inspect Wiring and Connections: Look for frayed wires, loose connections, or corrosion that may affect sensor readings.

- Test Battery: Check the battery charge and its terminals for cleanliness and secure connections.

Sensor Testing

- Sensor Replacement: If a sensor is found to be defective during diagnostics, replace it with a genuine John Deere part.

- Calibration: After replacing sensors, ensure that they are properly calibrated.

Mechanical Inspection

- Hydraulic System Examination: Look for leaks or other signs of failure in the hydraulic system.

- Comprehensive Repairs: If mechanical issues are suspected, mechanical repairs or replacements may be necessary.

After performing your repairs, reset any diagnostic codes using the service tool or follow the procedure outlined in the owner’s manual.

Estimated Repair Costs

The costs to address John Deere excavator warning lights problems can vary significantly based on the issue's nature:

- Fluid Change: $150 to $300, depending on the fluid type and service.

- Sensor Replacement: $50 to $600, based on the specific sensor and labor costs.

- Electrical Repairs: $75 to $200, depending on the complexity of the electrical issue.

- Mechanical Repairs: Can range from $500 to several thousand dollars depending on the extent of the repairs needed.

Performing regular maintenance can save money in the long run by avoiding major repair costs.

Prevention Tips

To prevent warning light issues in your John Deere excavator, consider the following tips:

- Regular Maintenance: Follow the scheduled maintenance outlined in the owner’s manual.

- Fluid Checks: Frequently check and top off all essential fluids, especially before each use.

- Clean Connections: Keep electrical connections clean and free from corrosion.

- Monitor Performance: Regularly observe the machine's performance for any signs of trouble.

- Use Genuine Parts: When replacing parts, always select genuine John Deere components to maintain reliability.

When to Seek Professional Help

While some issues might be resolved through basic troubleshooting, it is crucial to seek professional assistance when:

- Warning lights persist after completing maintenance and diagnostics.

- Unusual symptoms arise, such as severe vibration or loss of power.

- Complex repairs are needed that exceed DIY capabilities, such as engine or hydraulic repairs.

Consulting a qualified John Deere technician can help avoid further complications.

Conclusion

In summary, John Deere excavator warning lights serve a vital purpose in maintaining the health and efficiency of the machine. Owners and operators must pay attention to these warning indicators to prevent significant breakdowns and ensure productivity on the job site. By understanding the symptoms, possible causes, diagnosis steps, and repair processes, you can maintain your John Deere excavator efficiently.

Key takeaways:

- Always monitor your equipment and stay ahead of maintenance schedules.

- Understand the implications of warning lights and don’t ignore them.

- Regular checks and maintenance can significantly prolong the life of your excavator.

By staying informed and proactive, you can ensure a smoother, safer operation of your John Deere excavator without the disruptions caused by warning lights.It seems like you want to continue a specific topic or conversation. Could you please provide more context or specify what you'd like to continue discussing?