John Deere R4038 Sprayer is a powerful and efficient machine designed for precision agriculture. However, like any complex machinery, it can encounter various issues over time. Understanding the common problems associated with the R4038 sprayer is crucial for maintaining operational efficiency and avoiding costly downtime. In this article, we'll dive into the frequent issues faced by owners, their symptoms, possible causes, and recommended troubleshooting steps.

| Symptoms | Possible Causes |

|---|---|

| Engine fails to start | Battery issues, fuel problems |

| Uneven spray patterns | Clogged nozzles, controller misconfigurations |

| Warning lights or codes | Electrical issues, sensor malfunctions |

| Leaking fluid | Damaged hoses, defective seals |

| Poor maneuverability | Tire pressure issues, hydraulic problems |

Key Takeaways

- The John Deere R4038 Sprayer is susceptible to various operational problems, ranging from engine malfunction to issues with the spraying mechanism.

- Regular maintenance and timely diagnosis can help prevent these issues.

- Many problems can be addressed through DIY methods, while some may require professional assistance.

Problem Description

The John Deere R4038 Sprayer, primarily utilized for applying fertilizers and pesticides, boasts advanced technology for efficient operation. However, several problems can arise, including:

- Mechanical Failures: Mechanical components can wear out or fail, leading to performance issues.

- Electrical Malfunctions: Sensors, wiring, and control systems may fail or produce error codes.

- Fluid Dynamics Issues: The sprayer's hydraulic system may leak or fail, affecting overall operation.

- Calibration Errors: Issues with the calibration can lead to ineffective spraying.

Owners should be aware that addressing problems early can prevent more serious issues and financial loss.

Common Symptoms

When a John Deere R4038 Sprayer begins to have problems, certain symptoms manifest that indicate the underlying issues. These include:

- Engine Starts but Stalls: Often a sign of fuel delivery issues or electrical system problems.

- Warning Lights Illuminate: Various warning lights, such as the hydraulic or engine light, may occur on the dashboard.

- Inconsistent Spray Patterns: This can affect the efficiency of herbicide and fertilizer application.

- Hydraulic Leaks: Noticeable fluid under the sprayer, often indicating failed hoses or seals.

- Unresponsive Controls: Difficulty in maneuvering or operating the sprayer as expected.

Understanding these symptoms is crucial for identifying the problem and initiating repairs.

Possible Causes

Each symptom has distinct potential causes. Let’s explore them in more detail:

-

Engine Starts but Stalls:

- Clogged fuel filters: Can restrict fuel flow.

- Weak battery: Insufficient power may lead to stalling.

- Faulty ignition system: Such as spark plugs or coils that fail under load.

-

Warning Lights Illuminate:

- Sensor or wiring issues: Faulty sensors can relay false information.

- Fluid level sensors: Low hydraulic fluid might trigger a warning.

-

Inconsistent Spray Patterns:

- Clogged nozzles: Debris buildup can block nozzle openings.

- Faulty control valves: Malfunctions can lead to uneven chemical application.

-

Hydraulic Leaks:

- Worn hoses: Age or stress can create leaks.

- Defective seals: Should be checked in the hydraulic system.

-

Unresponsive Controls:

- Controller failure: The electronic control unit may require recalibration or replacement.

- Hydraulic issues: Insufficient fluid can lead to incomplete movement of components.

Diagnosis Steps

To diagnose issues accurately with the John Deere R4038 Sprayer, follow these systematic steps:

-

Gather Information:

- Check the user manual for common errors and troubleshoot according to symptoms.

- Document any error codes displayed.

-

Examine Fluid Levels:

- Ensure that hydraulic fluid, engine oil, and fuel levels are sufficient and appropriate.

-

Inspect Connections and Wiring:

- Look for loose wires or corroded connectors, especially around sensors.

-

Run Diagnostic Tests:

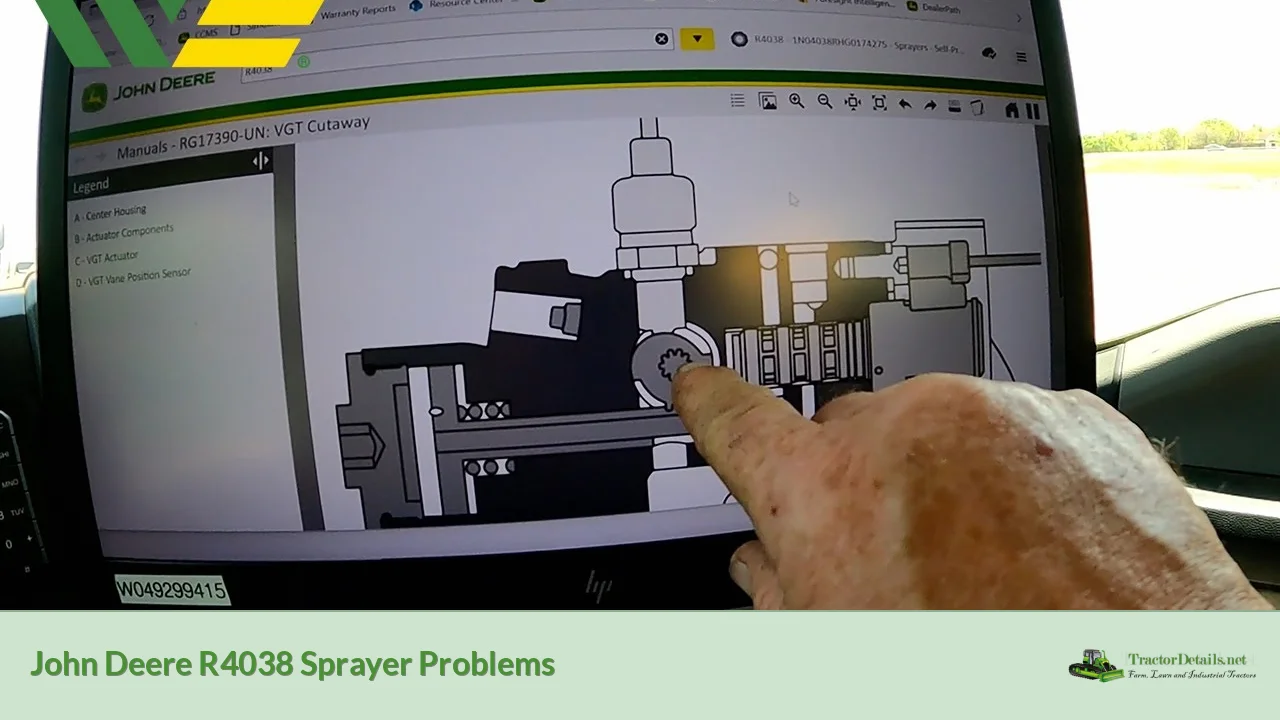

- Utilize diagnostic tools to read error codes from the control system. John Deere's Service Advisor software may provide insights.

-

Perform Visual Inspections:

- Check the condition of hoses, nozzles, and belts for any signs of wear or damage.

Troubleshooting and Repair Procedures

Depending on the problems diagnosed, here are specific troubleshooting and repair actions you can take:

Engine Issues

- Stalling Engine:

- Check Fuel Filters: Clean or replace clogged fuel filters.

- Examine Battery: Test the battery and replace if necessary.

Electrical Malfunctions

- Warning Lights:

- Error Code Retrieval: Pull diagnostic codes to identify issues.

- Sensor Replacement: Replace faulty sensors as indicated.

Fluid Dynamics Problems

- Hydraulic Leaks:

- Hose Inspection: If leaking, replace worn hoses and seals.

- Fluid Replacement: Ensure proper hydraulic fluid type and level are maintained.

Calibration Errors

- Inconsistent Spray Patterns:

- Nozzle Maintenance: Regularly clean or replace clogged nozzles.

- Recalibration: Follow the manufacturer’s guidelines for calibrating spray controllers.

General Maintenance Tips

- Replace worn belts, check tire pressure, and ensure regular fluid changes.

Each of these tasks can be executed by an experienced owner, but when in doubt, consulting a professional may save time and avoid further issues.

Estimated Repair Costs

Understanding potential costs associated with repairs can help you budget for necessary maintenance:

- Fluid Changes: $100 - $200 (depending on service location)

- Sensor Replacement: $150 - $500 (varies by sensor type)

- Nozzle Cleaning/Replacement: $20 - $100 per nozzle

- Hydraulic Hose Replacement: $50 - $150 per hose

- Electrical Repairs: $100 - $1,000 based on issue complexity

Consulting with local John Deere dealers or certified mechanics can provide more accurate estimates suited to your needs.

Prevention Tips

Preventative measures can help extend the life of the John Deere R4038 Sprayer and reduce the chances of problems:

-

Regular Maintenance Checks:

- Follow the maintenance schedule outlined in the owner's manual.

-

Visual Inspections:

- Frequently inspect hoses, wires, and nozzles for wear or damage.

-

Calibrate Often:

- Periodically recalibrating spray equipment ensures precise application.

-

Store Properly:

- Always keep the sprayer in a dry, sheltered environment to protect it from weather damage.

-

Educate Operators:

- Ensure all operators are trained on proper use to minimize operator-induced errors.

When to Seek Professional Help

While many R4038 issues can be diagnosed and repaired by experienced owners, some situations are best left to professionals:

- Persistent Warning Codes: If error codes persist despite troubleshooting.

- Complex Electrical Issues: Problems with the control system should be handled by certified technicians.

- Severe Fluid Leaks: If hoses or systems are failing rapidly.

- Calibrating Advanced Systems: Professional help may be preferable for ensuring precise calibration.

Conclusion

The John Deere R4038 Sprayer is a valuable asset for modern agriculture practitioners. Understanding the common problems, symptoms, possible causes, and appropriate responses is essential for maintaining this equipment. Whether you're addressing minor issues through DIY methods or enlisting the help of professionals for more serious problems, proactive maintenance and thorough troubleshooting are key in ensuring your sprayer remains operational.

Regular inspections, adherence to maintenance schedules, and prompt responses to any signs of trouble can save you both time and money. By actively managing the health of your John Deere R4038 Sprayer, you can maximize its efficiency and longevity, allowing you to focus on achieving the best results in your agricultural endeavors.It seems like you might want to continue a specific topic or text. Could you please provide more context or clarify what you'd like to continue discussing? This could be a story, a subject matter, or any other topic you're interested in.