When it comes to sewing machines, Kenmore is a well-established name, known for durability and reliability. However, even the most trusted models can develop issues, particularly with the bobbin case. Problems with the bobbin case can manifest in various ways, affecting the quality of your sewing and causing frustration for users. This article delves into Kenmore sewing machine bobbin case problems, offering insights into the symptoms, causes, diagnosis, troubleshooting steps, and more.

Key Takeaways

- Common issues with Kenmore sewing machines often originate from the bobbin case.

- Understanding symptoms can aid in quick diagnosis and resolution.

- Prevention and proper maintenance are essential to avoid bobbin-related problems.

- Know when to seek professional assistance if DIY solutions don't work.

| Symptoms | Possible Causes |

|---|---|

| Unthreaded bobbin | Incorrect bobbin insertion |

| Thread bunching | Bobbin case misalignment or damage |

| Skipped stitches | Cotton thread caught in bobbin case |

| Unusual noises | Worn-out bobbin or case |

| Thread breaking frequently | Incorrect tension or bobbin size |

Problem Description

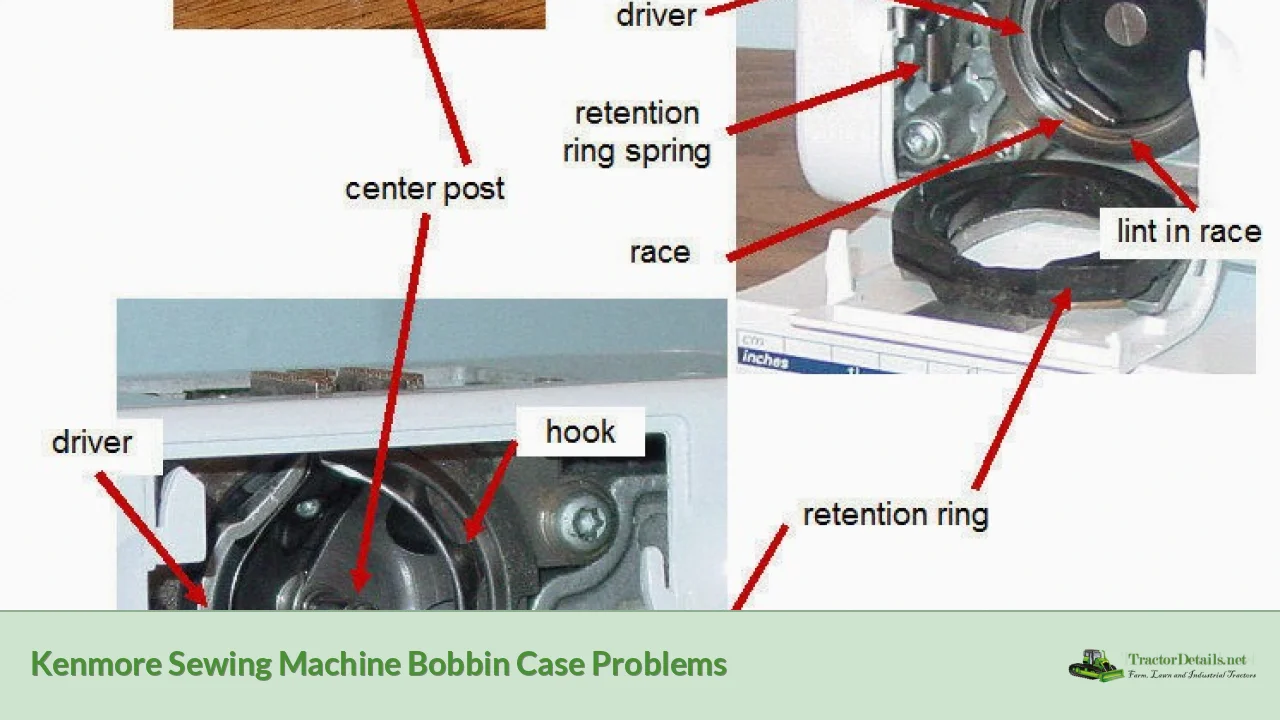

Issues with the bobbin case are not only frustrating but can also significantly impede your sewing projects. The bobbin case holds the bobbin securely and allows for the thread to be fed appropriately as you sew. Problems can arise from various factors, including improper installation, mechanical wear and tear, or misalignment, resulting in compromised sewing performance.

Frequent problems include:

- Misaligned bobbin case

- Damaged bobbin or thread

- Improper tension settings

- Debris accumulation in the bobbin area

Common Symptoms

Identifying the symptoms of bobbin case problems is crucial for prompt action. Some common symptoms you might experience include:

- Unthreaded bobbin: If the bobbin consistently unthreads, it may not be seated properly.

- Thread bunching: Thread may bunch up, indicating misalignment or a snag in the bobbin mechanisms.

- Skipped stitches: This is often due to tangles in the bobbin case or tension issues.

- Unusual noises: Grinding or clunking sounds can indicate that the bobbin case is worn out.

- Frequent thread breaking: This could stem from incorrect bobbin size, tension issues, or wear on the bobbin itself.

Understanding these symptoms helps you quickly determine the problem’s nature.

Possible Causes

A variety of factors can contribute to issues with the bobbin case in Kenmore sewing machines. Here are some possible causes to consider:

- Incorrect bobbin insertion: Not placing the bobbin in the casing properly can lead to operational issues.

- Damage to the bobbin case: Cracks or wear can affect functionality.

- Tension problems: An incorrect tension setting can cause thread to break or bunch.

- Debris accumulation: Dust and lint can inhibit movement, causing jams.

- Misalignment: The bobbin case may need adjustment or realignment.

Diagnosis Steps

To diagnose bobbin case issues, follow these systematic steps:

- Power Off the Machine: Always ensure that the machine is unplugged when performing any maintenance or inspection.

- Remove the Bobbin Case: Carefully remove the bobbin casing and inspect for any evident damage or debris.

- Check Bobbin Installation: Ensure the bobbin is inserted correctly with the thread feeding in the correct direction: usually counter-clockwise.

- Examine the Tension Settings: Refer to your machine’s manual for correct tension settings based on thread type and fabric.

- Inspect for Debris: Clean the bobbin area thoroughly, removing any lint, dust, or thread remnants.

- Check the Alignment: Ensure that the bobbin case is seated correctly and does not wiggle when in place.

Troubleshooting and Repair Procedures

Once you've diagnosed the problem, you can proceed with the appropriate troubleshooting steps.

-

For unthreaded bobbins:

- Confirm that the bobbin is in the right orientation.

- Reseat the bobbin if necessary and check that it’s wound evenly.

-

For thread bunching:

- Rethread the entire machine, ensuring there are no twists or tangles.

- Clean the bobbin area thoroughly to remove any obstructions.

-

For skipped stitches:

- Check needle condition. A bent or dull needle can exacerbate this issue.

- Adjust the tension based on the fabric and thread type; it may need tightening or loosening.

-

For unusual noises:

- Apply sewing machine oil to the moving parts of the bobbin case, as lack of lubrication might be causing friction.

- Inspect the bobbin for wear; replace if necessary.

-

For frequent thread breaking:

- Ensure that you’re using the proper bobbin size for your Kenmore model.

- Adjust the thread tension according to the fabric’s weight.

Estimated Repair Costs

If you are unable to resolve the bobbin case issue through DIY methods, you may need professional help. Some estimated costs associated with bobbin case repairs are:

- Basic cleaning and maintenance: $50 - $100

- Bobbin case replacement: $100 - $150 (depending on the model)

- Full machine servicing: $150 - $300, which may include various repairs needed beyond the bobbin case.

Prevention Tips

To prevent bobbin case issues, consider the following tips:

- Regular maintenance: Periodically clean the bobbin area to prevent lint build-up.

- Use the correct bobbin type: Always use the recommended bobbin size as indicated in your Kenmore manual.

- Check tension settings regularly: Inconsistent tension can lead to various problems, so ensure settings are appropriate for your thread and fabric type.

- Store your machine properly: When not in use, cover your sewing machine to prevent dust accumulation.

When to Seek Professional Help

While many bobbin case issues can be resolved at home, there are certain situations where it's best to consult a professional:

- Persistent problems: If the issues persist after all troubleshooting efforts.

- Visible damage: If you notice any cracked or broken parts that might affect performance.

- Motor problems: Unusual noises could indicate deeper issues that require expert diagnosis.

- Electrical faults: If your machine is not turning on, or there are error codes appearing, professional help is necessary.

Conclusion

In summary, issues with the bobbin case of your Kenmore sewing machine can lead to significant frustration during projects. By identifying common symptoms, understanding possible causes, and following diagnostic and troubleshooting steps, you can effectively manage many of these problems yourself. Regular maintenance and care for your machine will help prevent bobbin-related issues and enhance your sewing experience. If difficulties persist despite your efforts, don't hesitate to seek professional assistance to ensure your sewing machine operates smoothly.

For Kenmore sewing machine owners, keeping these pointers in mind can mean the difference between a smooth, enjoyable sewing experience and one filled with interruptions and challenges.It seems like you might want to continue a conversation or a topic. Could you please provide more details or specify what you would like to continue discussing?