Kenworth trucks, renowned for their reliability and durability, can still encounter electrical problems which can significantly affect their performance. Whether you're a professional driver or an owner-operator, understanding these issues is crucial for maintaining your vehicle's efficiency and safety. This article provides an in-depth exploration of Kenworth electrical problems, covering symptoms, causes, diagnosis, troubleshooting, repair procedures, and more.

Key Takeaways

- Kenworth electrical issues can manifest through various symptoms including warning lights, frequent battery drains, and malfunctioning electronic components.

- Common causes include wiring damage, battery failures, and faulty fuses.

- Diagnosing electrical problems often requires specialized tools and knowledge of Kenworth's electrical systems.

- Regular maintenance and inspections can prevent many electrical issues from arising.

- Seeking professional help is recommended for complex problems or when diagnostic tools are needed.

| Symptoms | Possible Causes |

|---|---|

| Warning lights illuminated | Faulty sensors or wiring issues |

| Malfunctioning lights | Blown fuses or relay problems |

| Battery drain | Aging batteries or parasitic draw |

| Issues with ECU communication | Corroded connectors or damaged wiring |

Problem Description

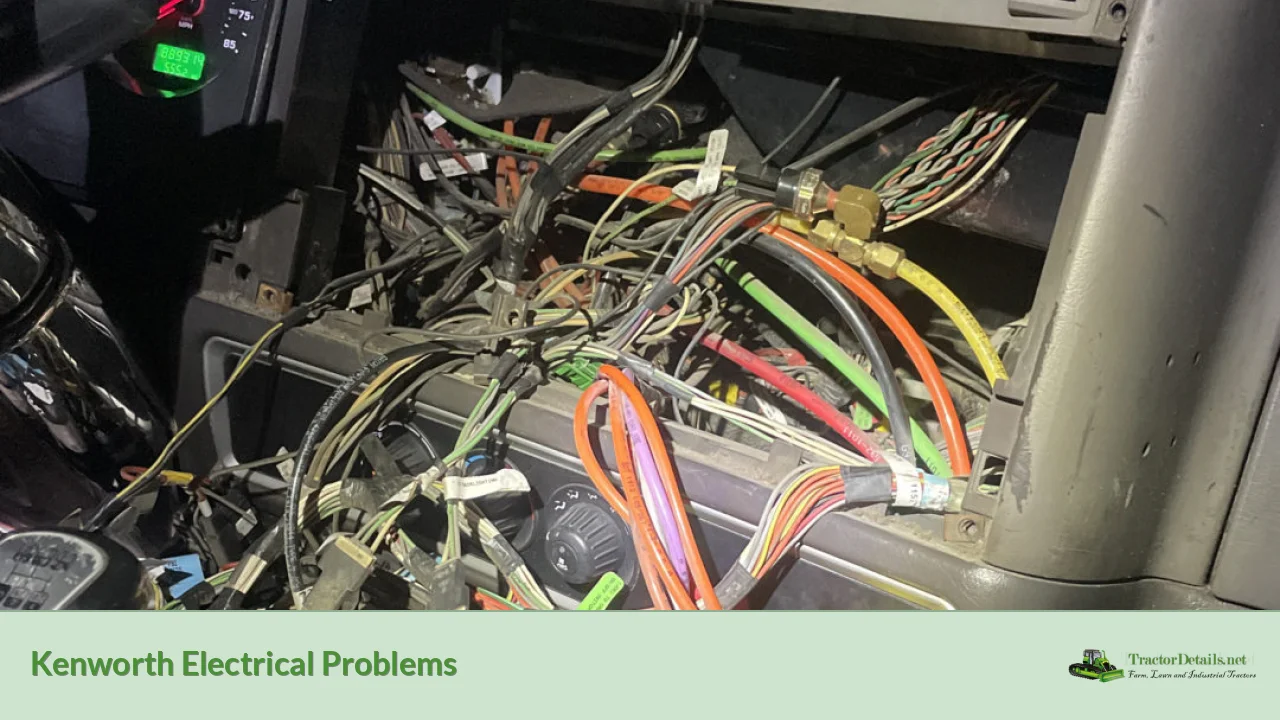

Kenworth trucks, like all vehicles, incorporate a complex electrical system that controls everything from engine management to cabin comforts. Problems in this system can be frustrating and challenging to diagnose. Electrical issues can range from simple problems like a blown fuse, to more complex failures involving the engine control unit (ECU).

Some specific models such as the Kenworth T680, W990, and T800 often exhibit particular electrical problems common to their design. Understanding these problems is crucial for timely resolution and avoiding extensive downtime.

Common Symptoms

Owners of Kenworth trucks may notice various symptoms when electrical problems arise. Identifying these symptoms early can help avoid serious issues down the line. Common symptoms include:

- Warning lights on the dashboard, such as the Check Engine or Battery light

- Malfunctioning gauges indicating incorrect readings for oil pressure, temperature, etc.

- Frequent battery drains, leading to starting issues

- Flickering or malfunctioning headlights

- Electrical components failing to operate (e.g., heating, air conditioning, or powered windows)

- Dimming dashboard lights

Possible Causes

Electrical issues in Kenworth trucks can stem from various sources. Understanding these potential causes will aid in diagnosis and repair efforts. Common causes include:

- Wiring damage: Brittle, corroded, or frayed wires can lead to short circuits or open circuits, interrupting power flow.

- Battery problems: A failing battery, or one that is nearing the end of its life, can lead to performance issues.

- Faulty fuses and relays: A blown fuse can cut power to critical systems, while a defective relay can prevent electrical signals from reaching their intended destination.

- Corroded connectors: Connections can corrode over time, leading to poor conductivity and intermittent faults.

- Malfunctioning ECU: The engine control unit may develop issues that cause multiple electrical components to fail.

Diagnosis Steps

Diagnosing electrical problems in a Kenworth truck requires a methodical approach. Follow these steps to identify the issue:

- Visual Inspection: Start by checking fuse boxes, looking for blown fuses, corroded terminals, and damaged wiring.

- Use a Multimeter:

- Check the battery voltage; it should be around 12.6 volts when fully charged.

- Test voltage at various points in the electrical system to find discrepancies.

- Scan for Error Codes: Use a diagnostic scanner compatible with Kenworth trucks to read trouble codes that can pinpoint specific issues with sensors or the ECU.

- Check Grounds: Make sure that all ground connections are secure and free of corrosion, as poor grounds can lead to a myriad of electrical problems.

- Component Testing: Isolate and test individual components such as relays, switches, and the ECU to see if they are functioning correctly.

Troubleshooting and Repair Procedures

Once the diagnosis is complete and the problem identified, the next step involves troubleshooting and repairing the affected system:

Battery and Charging System

- Battery replacement: If the battery is older than 3-5 years or shows low voltage during testing, consider replacing it.

- Charging system check: Use a multimeter to check the alternator's output; it should be between 13.8 to 14.5 volts when the engine is running.

Wiring and Connections

- Repair damaged wires: If any wires are frayed or damaged, splice in new wire or replace the harness if necessary.

- Clean connectors: Use a wire brush to clean corroded terminals and connections. Apply dielectric grease to prevent future corrosion.

Fuses and Relays

- Replace blown fuses: Use the owner's manual to locate the appropriate fuse and replace it with one of the correct amperage.

- Test and replace relays: If a relay is suspected, swap it out with a known good relay to determine if it resolves the issue.

ECU and Sensors

- Reflashing the ECU: If the ECU is malfunctioning, it may need to be reprogrammed or updated.

- Sensor verification: Test all relevant sensors to ensure they are functioning correctly and replace any that are faulty.

Estimated Repair Costs

Repair costs for electrical issues in Kenworth trucks can vary significantly based on the problem's complexity. Here’s a breakdown:

- Battery replacement: $150 - $300, depending on the battery type and the model of the truck.

- Wiring repairs: $100 - $400, depending on the extent of the damage and hours of labor required.

- Fuses and relays: $20 - $150 for parts and labor for replacement.

- ECU reprogramming: $100 - $500, depending on the dealer or service shop and whether specialized tools are required.

Prevention Tips

To minimize the risk of electrical problems, consider these proactive maintenance tips:

- Regular inspections: Conduct routine checks on the electrical system, focusing on connections, batteries, and fuses.

- Keep connectors clean: Regularly clean the battery terminals and electrical connectors to prevent corrosion.

- Monitor components: Keep an eye on components such as the alternator and starter motor, replacing them before they fail if they show signs of wear.

- Use high-quality parts: During replacements or upgrades, opt for OEM parts designed specifically for Kenworth trucks to ensure compatibility and reliability.

When to Seek Professional Help

While some electrical issues can be addressed with DIY efforts, certain situations call for professional expertise:

- Complex problems: If multiple systems are affected, it’s wise to enlist a trained technician.

- Lack of diagnostic tools: Professional mechanics have specialized equipment that can access more detailed diagnostics than are available to the average owner.

- Recurring problems: If you've repaired the same issue multiple times with limited success, a professional’s insight is invaluable.

Conclusion

In summary, electrical problems in Kenworth trucks can arise from various symptoms and underlying causes, ranging from simple wiring issues to complex ECU failures. Understanding the key symptoms and diagnostic steps is essential for every Kenworth owner. Regular maintenance and timely repairs can not only prevent major breakdowns but also extend the life of your vehicle. If the problems are too complex or persistent, don't hesitate to seek professional help, as they have the tools and expertise needed to get you back on the road safely.

By staying proactive and informed about the electrical systems in your Kenworth truck, you can drive with confidence, reducing downtime and ensuring optimal performance.Of course! What would you like to continue discussing or exploring? Please provide more details so I can assist you effectively.