Kenworth HVAC problems are a significant concern for many truck owners and operators. An efficient HVAC system is crucial for ensuring driver comfort and maintaining optimal operating conditions within the cab of a Kenworth truck. Not only can HVAC issues complicate the driving experience, but they can also indicate underlying mechanical problems. By understanding the symptoms and causes of these issues, Kenworth owners can take proactive measures to maintain their vehicles and minimize repair costs.

Key Takeaways

- Understanding Kenworth HVAC issues is vital for driver comfort and vehicle performance.

- Common symptoms include unusual sounds, insufficient cooling or heating, and strange odors.

- Possible causes range from clogged filters to refrigerant leaks and faulty components.

- Troubleshooting requires systematic diagnosis and proper tools.

- Timely intervention can prevent severe HVAC failures, saving on repair costs.

| Symptoms | Possible Causes |

|---|---|

| Insufficient heating | Clogged heater core |

| Unusual noises | Failing blower motor or fan |

| Refrigerant leak | Damaged hoses or fittings |

| Odors in the cabin | Moldy evaporator or cabin air filter |

| Excessive condensation | Faulty A/C compressor or expansion valve |

Problem Description

Kenworth trucks, known for their durability and comfort, utilize complex HVAC systems that manage heating, ventilation, and air conditioning. Issues with the HVAC system can lead to significant discomfort for drivers, particularly during extreme weather conditions. Common problems can result from wear and tear, lack of maintenance, or component failures.

These HVAC systems typically include:

- Heater Core: Transfers heat from the engine coolant to the air blown into the cabin.

- A/C Compressor: Pressurizes and circulates refrigerant throughout the system.

- Blower Motor: Controls the flow of air into the cabin.

- Evaporator Core: Cools the air by absorbing heat from the cabin air.

Understanding how each component functions can help in identifying and rectifying issues when they arise.

Common Symptoms

Identifying HVAC problems early can lead to easier and more affordable solutions. Common symptoms of HVAC issues in Kenworth trucks include:

- No Heat or Cold Air: The system fails to provide sufficient heating or cooling.

- Unusual Noises: Sounds like grinding, squealing, or rattling can indicate failing components.

- Unpleasant Odors: Musty or burnt smells can point to mold growth or electrical issues.

- Fogging Windows: Excess humidity and inadequate air circulation can cause condensation.

- Temperature Fluctuation: Rapid changes between hot and cold air suggests a malfunction.

Possible Causes

There are various reasons why Kenworth HVAC systems may fail to operate correctly. Understanding these potential causes can help pinpoint the problem:

- Clogged Cabin Air Filter: A dirty filter restricts airflow and reduces efficiency.

- Failed Blower Motor: This can prevent air from moving through the system.

- Refrigerant Leak: Deteriorating hoses or fittings can lead to lost refrigerant, affecting cooling.

- Faulty Thermostat: Impacts temperature regulation, leading to either overheating or underheating.

- Defective A/C Compressor: May interrupt refrigerant flow, resulting in insufficient cooling.

Diagnosis Steps

Diagnosing HVAC issues in Kenworth trucks should be approached systematically for effective results:

- Visual Inspection: Check for any visible damage to components, such as air filters, hoses, or the compressor.

- Listen for Noises: Turn on the HVAC system and listen for any unusual sounds that might indicate a failing component.

- Check Error Codes: Utilize an OBD-II scanner to retrieve any relevant error codes associated with HVAC malfunctions (if applicable).

- Test for Airflow: Evaluate air coming from the vents. Insufficient airflow may point to a clogged filter or failing blower motor.

- Assess Temperature: Monitor whether the air being blown is cold or hot and remains consistent throughout operation.

- Inspect Refrigerant Levels: Use a gauge to check refrigerant levels; low levels usually indicate a leak.

Troubleshooting and Repair Procedures

Addressing Kenworth HVAC problems can often be performed through troubleshooting steps. Here’s a structured approach for both DIY repairs and when to consider professional assistance:

DIY Solutions

-

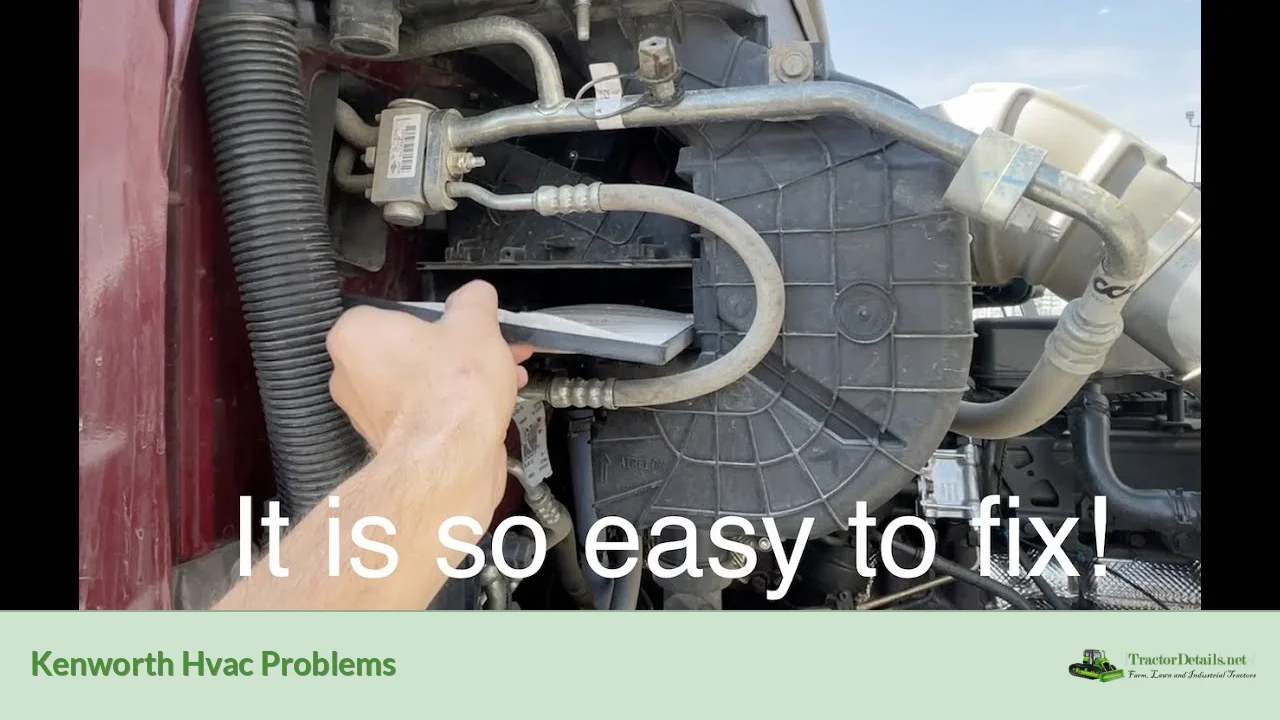

Replace Cabin Air Filter:

- Locate the cabin filter (usually accessible under the dashboard or behind the glove compartment).

- Remove the old filter, clean the housing, and insert a new filter before securing the access cover.

-

Clear Clogged Heater Core:

- Flush the heater core using compressed air or water to remove debris.

- Ensure coolant flows freely; replace if necessary.

-

Fix Blower Motor Issues:

- Identify and access the blower motor (typically found behind the glove box).

- Unplug the motor and test it using a multimeter.

- Replace if there are signs of damage or failure.

-

Recharge Refrigerant:

- Purchase a refrigerant recharge kit.

- Connect the gauge to the low-pressure valve and follow the directions on the kit.

Professional Repair Options

-

A/C Compressor Replacement:

- If the compressor is found defective through testing, a trained mechanic should replace it for best results.

-

Complete HVAC System Overhaul:

- In cases where multiple components have failed, professional service may offer a complete system check and replacement.

Estimated Repair Costs

Understanding potential repair costs can help Kenworth owners budget appropriately. Below are average costs associated with typical HVAC repairs:

- Cabin Air Filter Replacement: $20 - $50 (DIY) | $75 - $150 (Professional)

- Blower Motor Repair or Replacement: $100 - $300 (DIY) | $200 - $600 (Professional)

- Refrigerant Recharge: $30 - $150 DIY | $100 - $250 professional

- Compressor Replacement: $300 - $800 (DIY) | $500 - $1,200 (Professional)

- Full System Diagnostics: $75 - $150

(Note: Prices may vary based on location and labor costs.)

Prevention Tips

Preventing HVAC issues before they arise is crucial for long-term truck maintenance. Here are some proactive measures:

- Regular Maintenance: Schedule routine HVAC system checks, including filter replacements and refrigerant levels.

- Keep Vents Clear: Ensure that vents and intake areas are free from debris and obstructions.

- Monitor Cabin Air Quality: Use high-quality air filters that ensure cleaner airflow and reduce the risk of mold.

- Seasonal Checks: Before extreme weather conditions, inspect heating and cooling systems to ensure they are functioning properly.

When to Seek Professional Help

While many HVAC issues can be diagnosed and repaired independently, certain conditions warrant professional assistance. These include:

- Persistent Odors: If unusual smells continue after cleaning the components.

- Electrical Issues: Problems with the electrical system that impact component operation.

- Major Refrigerant Leaks: If a professional A/C service is needed to avoid environmental regulations or safety hazards.

- System Failures: When temperature controls do not respond despite troubleshooting efforts.

Conclusion

In summary, understanding the common HVAC problems associated with Kenworth trucks is essential for fleet maintenance and driver comfort. By recognizing symptoms, identifying possible causes, and conducting thorough diagnostic procedures, truck owners can address issues promptly. Implementing preventative measures and seeking professional assistance when necessary can help maintain an efficient and effective HVAC system. Regular maintenance not only improves the driving experience for operators but also helps save money on costly repairs in the long run. For Kenworth owners, being proactive is the best strategy to ensure a smoothly operating HVAC system.It seems like your message got cut off. Could you please provide more details or let me know what you would like to continue with? I'm here to help!