Kenworth trucks are renowned for their durability and reliability, making them a popular choice among trucking professionals. However, like any vehicle, they can experience issues, particularly with warning lights that indicate a problem within the system. Understanding these warning lights is vital for maintaining safety and efficiency on the road. Ignoring a warning light can lead to severe mechanical failures and costly repairs.

Key Takeaways

- Kenworth trucks utilize a variety of warning lights to alert drivers to potential issues.

- Common symptoms include dashboard alerts, engine performance changes, and unusual noises.

- Possible causes of warning lights can range from simple issues like low fluid levels to more serious engine faults.

- Prompt diagnosis and troubleshooting are crucial to prevent further damage and ensure safety.

- Regular maintenance can help in preventing warning light activation and extending the life of the truck.

| Symptoms | Possible Causes |

|---|---|

| Dash warning lights on | Low fluid levels, faulty sensors |

| Engine stalling | Fuel delivery issues, electrical faults |

| Reduced engine performance | Blocked air filters, ignition problems |

Problem Description

Kenworth trucks are equipped with an array of warning lights as part of their onboard diagnostic systems. These lights serve to alert drivers to issues ranging from simple maintenance needs—such as low oil or coolant levels—to more serious problems like brake malfunctions or engine failures. Each light has a specific meaning, and understanding these meanings is crucial for driver safety and truck performance.

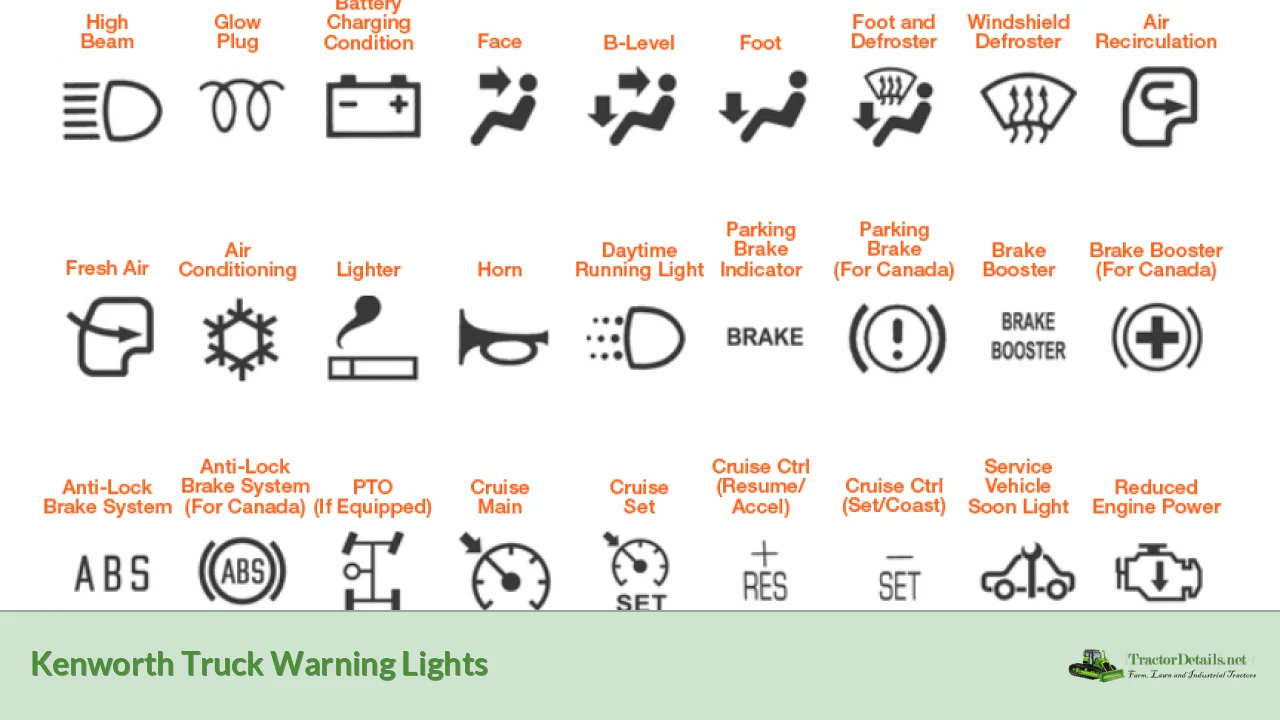

Common warning lights on Kenworth trucks include:

- Check Engine Light: Indicates a problem with the engine or emissions system.

- Oil Pressure Warning Light: Signals low oil pressure.

- Brake Warning Light: Alerts the driver to a braking system issue.

- Battery Warning Light: Indicates possible battery or charging system failure.

- ABS Warning Light: Shows an issue within the Anti-lock Braking System.

Common Symptoms

When warning lights illuminate on your Kenworth truck’s dashboard, several symptoms may accompany this alarming visual cue. Recognizing these symptoms is essential for timely intervention.

- Dashboard alerts: Various lights may flash or remain on, indicating potential issues.

- Changes in engine performance: These may include stalling, reduced power, or misfiring.

- Unusual noises: Sounds such as knocking or grinding may indicate mechanical issues.

- Fluid leaks: Puddles of oil, coolant, or other fluids can signal a leak.

- Unresponsive controls: Difficulty with steering, braking, or accelerating can also occur.

Possible Causes

Several factors can trigger warning lights on Kenworth trucks. While some are straightforward, others may require detailed diagnosis.

- Low fluid levels: Insufficient oil, coolant, or brake fluid can trigger multiple warning lights.

- Faulty sensors: Sensors that monitor fluid levels or engine performance may malfunction, causing false alerts or missed issues.

- Electrical faults: Issues with wiring, connectors, or the truck’s computer system can lead to erratic warning light behavior.

- Engine problems: Internal engine issues such as overheating, lack of fuel, or miscalibration can trigger the check engine light.

- Transmission issues: Problems with the transmission can affect vehicle performance and cause warning alerts.

Diagnosis Steps

Proper diagnosis is critical for identifying the root cause of warning lights. Kenworth trucks typically follow a systematic diagnostic procedure.

- Check the Owner's Manual: Start by consulting the truck's owner's manual for specifics related to the warning lights.

- Scan for Trouble Codes: Using an OBD-II scanner, retrieve any diagnostic trouble codes (DTCs) associated with the warning lights. Common codes include:

- P0420: Catalyst System Efficiency Below Threshold

- P0300: Random/Multiple Cylinder Misfire Detected

- Visual Intake Inspection: Check for any visible fluid leaks or electrical issues under the hood.

- Test Fluid Levels: Ensure that oil, coolant, and brake fluid levels are adequate.

- Inspect Electrical Connections: Verify that sensor wires and connectors are intact and secure.

- Examine Working Components: Inspect related components, such as pumps and filters, for functionality.

Troubleshooting and Repair Procedures

Once you’ve diagnosed the issue, the next step involves troubleshooting and repairing the problem while also being mindful of safety protocols.

- For low fluid levels:

- Top up fluids: Check and refill oil, coolant, and brake fluid as necessary.

- If a sensor is faulty:

- Replace the faulty sensor: Consult the Kenworth service manual for location and replacement procedure.

- For electrical faults:

- Inspect wiring and connections: Repair any damaged wires or loose connections. Utilize a multimeter to check for continuity.

- If engine performance is an issue:

- Inspect and replace worn components: Check the air filter, spark plugs, and fuel injectors; replace if necessary.

- For transmission problems:

- Seek professional help: Given the complexity, it’s advisable to consult a transmission specialist if issues persist.

Estimated Repair Costs

Repair costs can vary widely depending on the nature of the repair and the model of the Kenworth truck. Here’s a general breakdown:

- Fluid top-ups: $10 to $50, depending on fluid types.

- Sensor replacement: $50 to $300, including parts and labor.

- Electrical repairs: $100 to $500, depending on the extent of wiring issues.

- Engine repairs: $200 to $2,000+, depending on the issue severity and parts required.

- Transmission overhaul: $1,000 to $5,000+, based on the model and type of repairs needed.

It’s essential to get multiple quotes from reputable shops and use OEM parts for repairs whenever possible, ensuring quality and reliability.

Prevention Tips

To minimize the risk of warning lights appearing in the future, implement the following preventive measures:

- Regular Maintenance: Schedule routine checks for oil, coolant, and brake fluid levels.

- Electrical System Inspection: Periodically inspect wiring and connections for wear and tear.

- Software Updates: Ensure that the truck’s onboard software is up-to-date to avoid diagnostic discrepancies.

- Monitoring and Diagnostics: Use onboard monitoring tools to keep an eye on performance metrics.

- Professional Check-ups: Consult a professional at least once a year for a comprehensive inspection.

When to Seek Professional Help

While some minor problems may be addressed through DIY methods, certain situations necessitate professional intervention:

- Persistent warning lights: If warning lights remain illuminated after initial troubleshooting.

- Complex repairs: Issues related to the transmission, major engine components, or electrical systems should be left to experienced mechanics.

- Lack of tools: If you don’t have the required tools or diagnostic equipment, consult a professional.

- Safety concerns: If the warning light pertains to critical systems like brakes or steering, immediate professional attention is necessary.

Conclusion

Understanding and addressing warning lights on Kenworth trucks is vital for ensuring the longevity and safety of your vehicle. Prompt recognition of warning lights, combined with a systematic approach to diagnosis and repair, can prevent costly failures and improve overall vehicle performance.

- Always keep an eye on your truck’s dashboard and be aware of any symptoms or changes in performance.

- Regular and proactive maintenance is key to preventing issues that can lead to warning light activation.

- When in doubt, don’t hesitate to seek professional help, especially for persistent or serious issues.

By following these guidelines, Kenworth truck owners can maintain their vehicles effectively and enjoy a safer driving experience.It looks like your message was cut off. Could you please provide more context or clarify what you would like to continue about? Whether it's a story, a topic, or something else, I'm here to help!