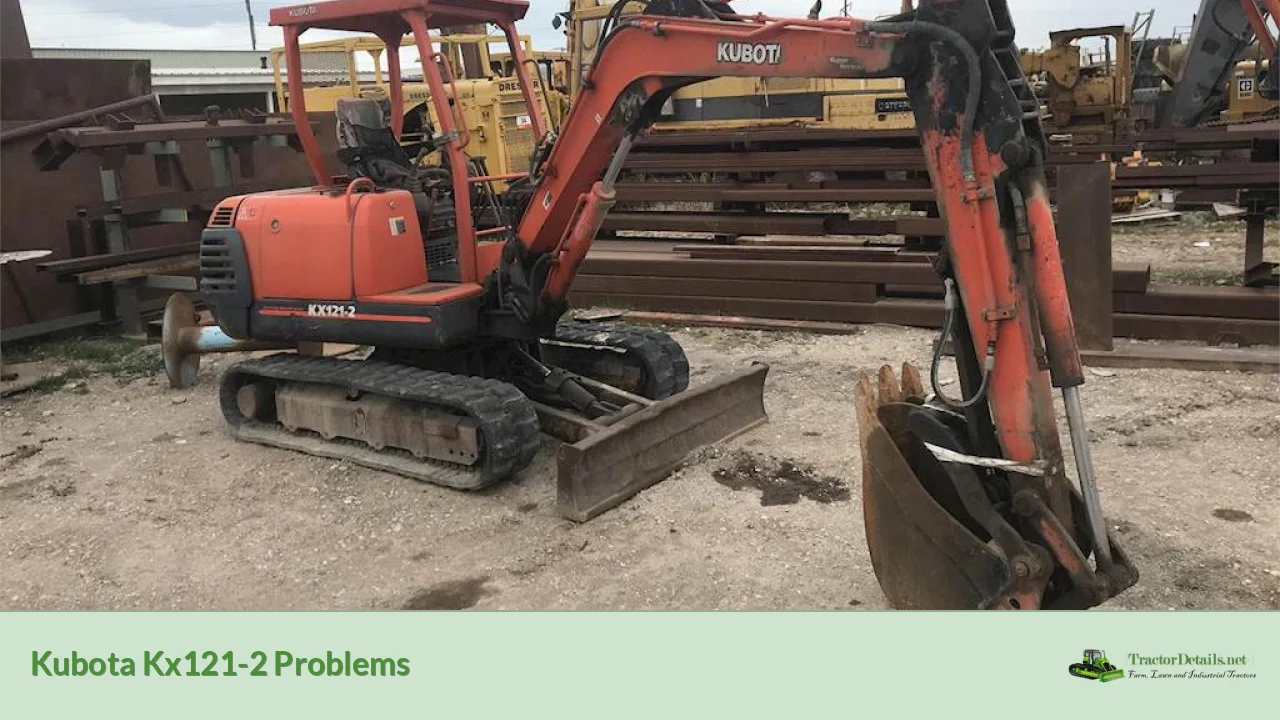

Kubota KX121-2 is renowned for its reliability and performance in the compact excavator market. However, like any heavy machinery, it can encounter various problems over time. Understanding these potential issues, their symptoms, and solutions can significantly extend the lifespan of the machine and enhance productivity.

Key Takeaways

- The Kubota KX121-2 may experience common issues such as hydraulic system failures, electrical problems, and engine troubles.

- Early diagnosis and troubleshooting can prevent more severe damage and costly repairs.

- Regular maintenance and adherence to operating guidelines are essential for longevity.

- Seek professional assistance if you're unable to identify or address the issue effectively.

| Symptoms | Possible Causes |

|---|---|

| Hydraulic fluid leaks | Damaged hoses or seals |

| Engine stalling | Clogged fuel filter |

| Warning lights on the dashboard | Electrical system malfunction |

| Inadequate power during operation | Worn hydraulic pump |

Problem Description

The Kubota KX121-2 is a versatile and durable machine, widely used for various excavation tasks. Despite its robust design, problems can arise, often leading to downtime and increased operational costs. Common problems include issues with the hydraulic system, engine performance, and electrical systems. Knowing these potential problems allows operators to address them quickly and maintain optimal functionality.

Common Symptoms

Several symptoms can indicate underlying problems with the Kubota KX121-2. Recognizing these signs early can help mitigate serious damage.

- Hydraulic Fluid Leaks: Visible pools of hydraulic fluid around the machine can indicate an issue with hoses or seals.

- Engine Stalling: If the engine frequently stalls during operation, it may point to fuel delivery problems.

- Warning Lights Activated: Warning lights on the dashboard can indicate various issues, including overheating or electrical faults.

- Inadequate Power: A noticeable drop in performance or power might suggest wear in the hydraulic pump or other components.

Possible Causes

Identifying the root causes of these symptoms can guide effective troubleshooting. Here’s a breakdown of potential causes:

-

Hydraulic Fluid Leaks:

- Damaged hoses or fittings

- Worn seals or gaskets

- Overfilled hydraulic fluid tank

-

Engine Stalling:

- Clogged fuel filter or fuel lines

- Dirty air filter restricting airflow

- Low engine oil levels

- Electrical issues affecting fuel injection

-

Warning Lights Activated:

- Faulty sensors or wiring in the electrical system

- Overheating due to low coolant levels or coolant leaks

- Electrical overloads

-

Inadequate Power:

- Worn hydraulic pump or components

- Improperly adjusted hydraulic settings

- Clogged hydraulic filters

Diagnosis Steps

To effectively diagnose issues with the Kubota KX121-2, follow these structured steps:

-

Check Fluid Levels:

- Inspect hydraulic fluid and engine oil levels. Ensure they meet manufacturer specifications.

-

Inspect Hoses and Connections:

- Look for visible signs of wear or leaks in the hydraulic hoses and connections. Replace if necessary.

-

Examine the Dashboard:

- Take note of any warning lights. Utilize the machine’s operator manual to interpret the lights' meanings.

-

Test Engine Performance:

- Monitor engine behavior during operation. Note any irregular stalling or power loss.

-

Check Filters:

- Inspect and, if necessary, replace the fuel and air filters to ensure they are not causing flow restrictions.

-

Run Diagnostic Tests:

- Many Kubota models come with onboard diagnostic capabilities. Use these to retrieve error codes for further insight.

Troubleshooting and Repair Procedures

Once diagnosis is complete, the following troubleshooting and repair procedures can be undertaken:

Hydraulic System Issues

-

Identify and Replace Leaking Hoses:

- Inspect each hose for wear and replace any that appear damaged.

-

Seal Replacement:

- For minor leaks, consider replacing seals and gaskets at affected joints.

Engine Management Problems

-

Fuel System Maintenance:

- Clean or replace clogged fuel filters and ensure fuel lines are clear.

- Check the fuel tank for contamination.

-

Air Filter Cleaning:

- Clean or replace the air filter to ensure optimal airflow.

Electrical System Repairs

-

Wiring Inspection:

- Visually inspect electrical wiring for damage, corrosion, or disconnections.

-

Sensor Replacement:

- If a warning light remains on after making mechanical repairs, test and replace faulty sensors.

General Maintenance

-

Regular Maintenance Checks:

- Establish a routine for checking fluid levels, filters, and overall machine performance.

-

Update Operator Training:

- Ensure that operators are knowledgeable about machine operations and common issues to prevent misuse.

Estimated Repair Costs

Understanding the potential repair costs can help operators budget accordingly:

- Hydraulic System Repairs:

- Hose replacement: $100 - $300

- Seal replacements: $50 - $150

- Engine Repairs:

- Fuel filter replacement: $30 - $100

- Air filter replacement: $20 - $60

- Electrical Repairs:

- Sensor replacement: $50 - $200

- Wiring repairs: $100 - $400 depending on complexity

Labor costs vary widely, so obtaining estimates from certified Kubota mechanics is advisable for a more accurate picture.

Prevention Tips

Preventative maintenance can save time and expenses in the long run. Here are some tips:

-

Follow Maintenance Schedule:

- Adhere to the manufacturer-recommended maintenance schedule outlined in the operator’s manual.

-

Regular Inspections:

- Conduct frequent visual and operational inspections to catch small issues before they escalate.

-

Use Quality Components:

- When replacing parts, use OEM (Original Equipment Manufacturer) components to ensure compatibility and quality.

-

Educate Operators:

- Provide training to operators about the proper use and maintenance of the KX121-2 to prevent operator-induced problems.

When to Seek Professional Help

While many issues can be tackled by the owner or operator, some situations warrant professional attention:

-

Complex Electrical Issues:

- If available diagnostic tools report complex error codes not easily interpreted by the owner.

-

Severe Hydraulic Failures:

- When there is significant hydraulic failure, leading to complete loss of function.

-

Engine Overhaul:

- If repairs require engine disassembly or are extensive.

-

Liability Concerns:

- When operating in safety-sensitive environments or when compliance with regulations is in question.

Conclusion

The Kubota KX121-2 is a dependable excavator, but like any machine, it can face problems if not properly maintained. Recognizing symptoms early and executing a methodical approach to diagnosis and resolution are keys to minimizing downtime and repair costs.

Taking proactive steps for maintenance, utilizing quality parts, and ensuring operators are trained, will significantly enhance the longevity and performance of your KX121-2. Don't hesitate to engage a professional mechanic for complex issues, as their expertise can be invaluable in safeguarding your investment. By staying informed and vigilant, you can ensure that your Kubota KX121-2 remains a reliable asset for years to come.Of course! What would you like to continue discussing or exploring? Please provide more details or context, and I'll be happy to assist!