Identifying problems with a Massey Ferguson 35 4 Cylinder Diesel can be daunting for operators, especially when it comes to starting difficulties. This article will dive deep into the potential causes, symptoms, and solutions to these issues. By understanding the complexity of starting problems, tractor owners can take appropriate steps to ensure reliable performance and minimize downtime.

Key Takeaways

- Massey Ferguson 35 is a robust tractor but can experience starting issues that require troubleshooting.

- Common symptoms include slow cranking, no start, and engine sputter.

- Potential causes range from battery issues to fuel system problems and electrical faults.

- Both DIY and professional solutions exist to remedy these starting issues.

- Routine maintenance can prevent many common problems.

| Symptoms | Possible Causes |

|---|---|

| No cranking sound | Faulty battery, starter motor issues |

| Slow or labored cranking | Weak battery, poor connections |

| Engine cranks but won't start | Fuel delivery issues, air leaks |

| Engine sputters during start | Fuel contamination, air in the fuel system |

Problem Description

Massey Ferguson 35 tractors are known for their durability and efficiency. However, like any piece of machinery, they can develop issues over time. Starting problems can manifest in various ways, leading to frustration for users.

Inadequate starting can be attributed to multiple systems within the tractor, including the fuel delivery system, electrical components, and even mechanical failures. Understanding these systems is paramount for troubleshooting and securing a quick resolution.

Common Symptoms

When dealing with starting issues in the Massey Ferguson 35, users may notice several telling signs. Recognizing these can expedite the diagnosis process.

- No Cranking: When you turn the key but hear no sound, it may indicate a complete disconnect in the starting system.

- Slow Cranking: A sluggish response when turning the key can hint at battery or electrical issues.

- Spotty Start: The engine may crank for a few moments but then die, suggesting fuel delivery problems.

- Sputtering upon Start: This often points to fuel contamination or air getting mixed with the fuel.

Possible Causes

Some potential issues can often affect starting performance:

- Battery Problems: Weak or dead batteries can result in insufficient power.

- Starter Motor Issues: A malfunctioning starter motor can prevent the engine from cranking effectively.

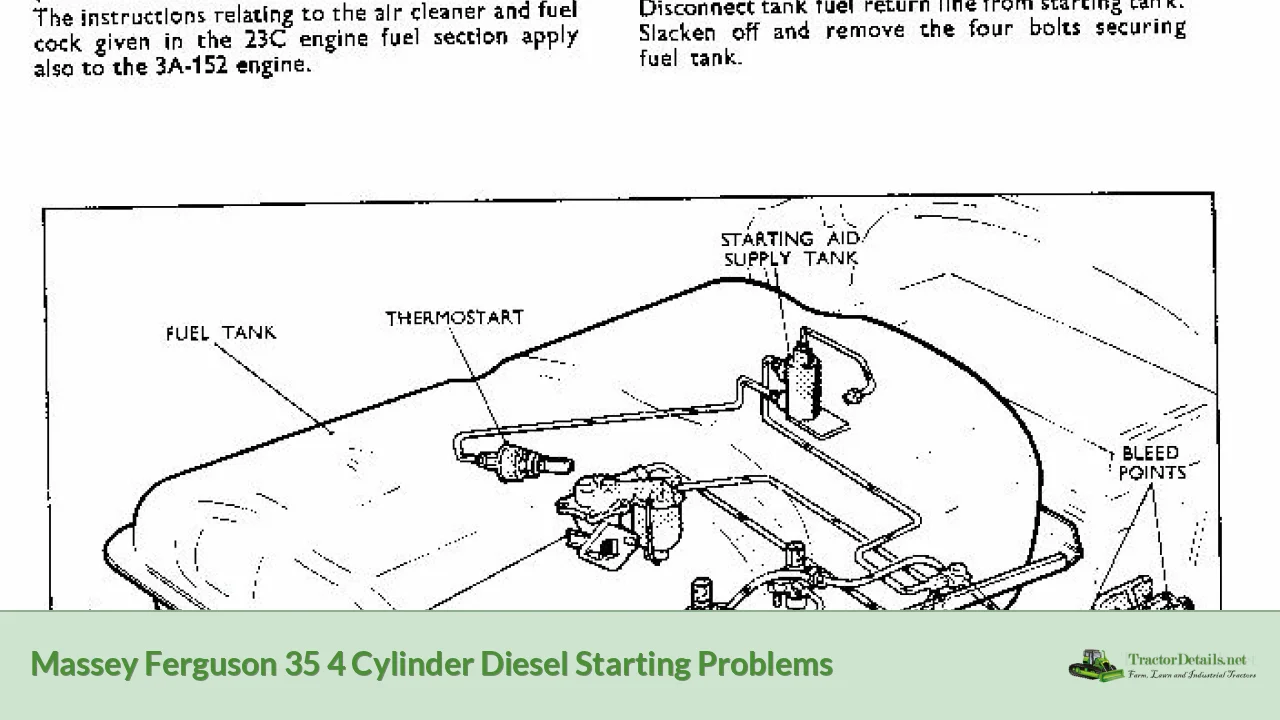

- Fuel Delivery Problems: Clogged filters, air leaks, or a faulty injector pump can disrupt fuel flow.

- Electrical Issues: Poor connections or damaged wiring can interrupt the starting circuit.

- Mechanical Failure: Internal engine problems may be harder to identify but can lead to starting issues.

Diagnosis Steps

Before delving into repairs, proper diagnosis is crucial. Here’s how to approach it:

-

Check the Battery:

- Measure the voltage with a multimeter; it should be above 12.4 volts.

- Inspect battery terminals for corrosion and ensure they're tightly connected.

-

Inspect the Fuel System:

- Check the fuel level to ensure there's enough fuel in the tank.

- Examine the fuel filter for contamination.

- Inspect the fuel lines for leaks and air.

-

Starter and Connections:

- Listen for any unusual noises when attempting to start; this may indicate starter issues.

- Check the wiring for frays or damage, particularly around the ignition switch.

-

Electrical System Check:

- Use a multimeter to test fuses and ensure all electrical connections are intact.

Troubleshooting and Repair Procedures

Once you’ve pinpointed potential issues, consider the following steps for resolving the problems:

-

For Battery Problems:

- Clean the terminals and connections.

- Jump-start the tractor if the battery is weak.

- Replace the battery if it fails to hold a charge.

-

If the Starter is Defective:

- Inspect the starter connections for debris or damage.

- Test the starter motor with a multimeter and replace it if necessary.

-

Addressing Fuel Delivery Issues:

- Replace the fuel filter if clogged.

- Clear any air in the fuel system by bleeding it.

- Ensure the fuel pump is operational and replace it if it fails.

-

Resolving Electrical Issues:

- Repair or replace damaged wiring.

- Secure connections around the battery, starter, and ignition system.

Estimated Repair Costs

Repair costs can vary significantly depending on what's wrong with your tractor:

- Battery replacement: $100 to $200

- Starter motor replacement: $200 to $400

- Fuel system repairs: $150 to $800 depending on severity

- Electrical repairs: $100 to $300 depending on complexity

DIY repairs can save money, but serious issues should be addressed by professionals, especially if you lack experience.

Prevention Tips

To prevent starting problems down the line, regular maintenance is essential:

- Routine Battery Checks: Clean the terminals every few months and check voltage levels.

- Fuel System Maintenance: Replace filters regularly and ensure clean fuel is always used.

- Electrical System Inspections: Regularly inspect wiring and connections for any signs of wear-and-tear.

- Regular Run Times: Ensure the tractor is run periodically to keep the battery charged and components lubricated.

When to Seek Professional Help

While many starting problems can be addressed through DIY troubleshooting, some situations warrant professional intervention:

- If you cannot isolate the problem after thorough checks.

- When you lack the tools or technical expertise.

- For internal mechanical failures that require advanced diagnostics.

- If electrical issues are persistent, potentially jeopardizing safety.

A qualified mechanic familiar with Massey Ferguson tractors can provide invaluable assistance.

Conclusion

Massey Ferguson 35 4 Cylinder Diesel starting problems can be traced back to a variety of issues related to the battery, starer motor, fuel system, and electrical components.

Regular maintenance and inspections can significantly reduce the likelihood of encountering these issues. When diagnosed correctly, many problems can be solved with DIY methods, while serious issues may require professional help.

Understanding the key symptoms and possible causes, along with a structured approach to diagnosis and repair, will empower owners to address starting problems effectively. By maintaining awareness and staying proactive with care, you can keep your Massey Ferguson 35 running smoothly and efficiently, ready for any task it faces.Of course! However, I'll need more context to continue. Could you please provide more details or specify what you want to continue with? It could be a story, an explanation, or anything else you have in mind!