Massey Ferguson tractors are widely respected in the agricultural industry for their durability and performance. However, like any machine, they can experience mechanical issues, particularly with the clutch system. Clutch problems can lead to decreased efficiency and productivity, making it vital for operators to quickly identify and resolve these issues. The clutch is essential for engaging and disengaging the power from the engine to the transmission, allowing the driver to control the speed and power of the tractor. When problems arise, they can greatly affect the tractor's performance and the operator's ability to perform necessary tasks.

Key Takeaways

- Common symptoms of clutch problems include difficulty in shifting gears, unusual noises, and a soft or unresponsive clutch pedal.

- Possible causes range from worn components to hydraulic issues.

- Regular maintenance and inspections can prevent many clutch problems.

- Professional help should be sought when the problem is beyond basic DIY repairs.

| Symptoms | Possible Causes |

|---|---|

| Difficulty in shifting gears | Worn clutch plates |

| Soft or unresponsive clutch pedal | Low hydraulic fluid levels |

| Unusual noises when disengaging | Damaged release bearing |

| Excessive clutch slippage | Misadjusted clutch linkage |

Problem Description

The clutch system in Mas خم264, 275, and 299 models is integral for smooth functionality and operates under high tension. Problems can occur due to wear and tear, incorrect adjustments, or hydraulic failures. Issues may escalate if not addressed promptly, leading to more severe damage or costly repairs.

- Worn Clutch Plates: Over time, clutch plates can wear out due to normal usage. This reduces the effectiveness of the clutch, leading to slippage.

- Hydraulic Issues: Many Massey Ferguson tractors employ hydraulic systems for clutch operation. Low fluid levels or leaks can impede the clutch's ability to engage properly.

- Mechanical Failures: Various mechanical components, such as the release bearing or clutch fork, can fail and cause operational issues.

Common Symptoms

Recognizing the symptoms of clutch problems is crucial. Here are some common signs that your Massey Ferguson tractor may be experiencing clutch issues:

- Difficulty in Shifting Gears:

- Grinding noises while shifting

- Inability to engage certain gears

- Soft or Unresponsive Clutch Pedal:

- Clutch pedal feels loose or spongy

- Lack of resistance when pressing the pedal

- Unusual Noises When Disengaging:

- Grinding or scraping sounds

- Loud screeching or clanking noises

- Excessive Clutch Slippage:

- Engine revs but the tractor does not gain speed

- Jerky motion during acceleration

Possible Causes

Understanding the possible causes of these symptoms can help in diagnosing the problem effectively. Some common causes include:

- Worn Clutch Plates:

- Resulting from prolonged usage without adequate maintenance.

- Low Hydraulic Fluid Levels:

- Hydraulic issues arise from fluid leaks or lack of fluid.

- Misadjusted Clutch Linkage:

- If the clutch pedal is not adjusted correctly, it can affect engagement and disengagement.

- Damaged Release Bearing:

- Worn or broken bearings can cause noise and affect clutch operation.

Diagnosis Steps

When faced with clutch problems, diagnosing the issue accurately is essential. Follow these steps to identify the root cause:

-

Visual Inspection:

- Check for any visible leaks or fluid levels in the hydraulic reservoir.

- Inspect the clutch pedal linkage and adjust if necessary.

-

Fluid Check:

- Ensure that hydraulic fluid levels are adequate.

- Look for discolored or contaminated fluid, which may require a flush and refill.

-

Clutch Pedal Test:

- Press the clutch pedal to check for resistance. A soft pedal indicates potential hydraulic issues.

-

Listen for Noises:

- Start the tractor and listen for any unusual sounds when engaging and disengaging the clutch.

-

Consult Error Codes:

- Use diagnostic equipment to read any error codes, if applicable.

Troubleshooting and Repair Procedures

Once the issue is diagnosed, appropriate troubleshooting and repair procedures can be determined:

For Worn Clutch Plates:

- DIY Solution:

- If you're mechanically inclined, you can replace the clutch plates yourself. Make sure to:

- Disconnect the battery.

- Remove the transmission cover.

- Replace the old plates with new ones and reassemble the components.

- If you're mechanically inclined, you can replace the clutch plates yourself. Make sure to:

- Professional Repair:

- Hire a certified mechanic to perform the replacement. This is advisable for those unfamiliar with heavy machinery repairs.

For Low Hydraulic Fluid:

- DIY Solution:

- Check and fill the hydraulic fluid reservoir. Utilize the manufacturer-recommended fluid type.

- Professional Repair:

- If leaks are present, consult a technician to locate and repair the source of the leak.

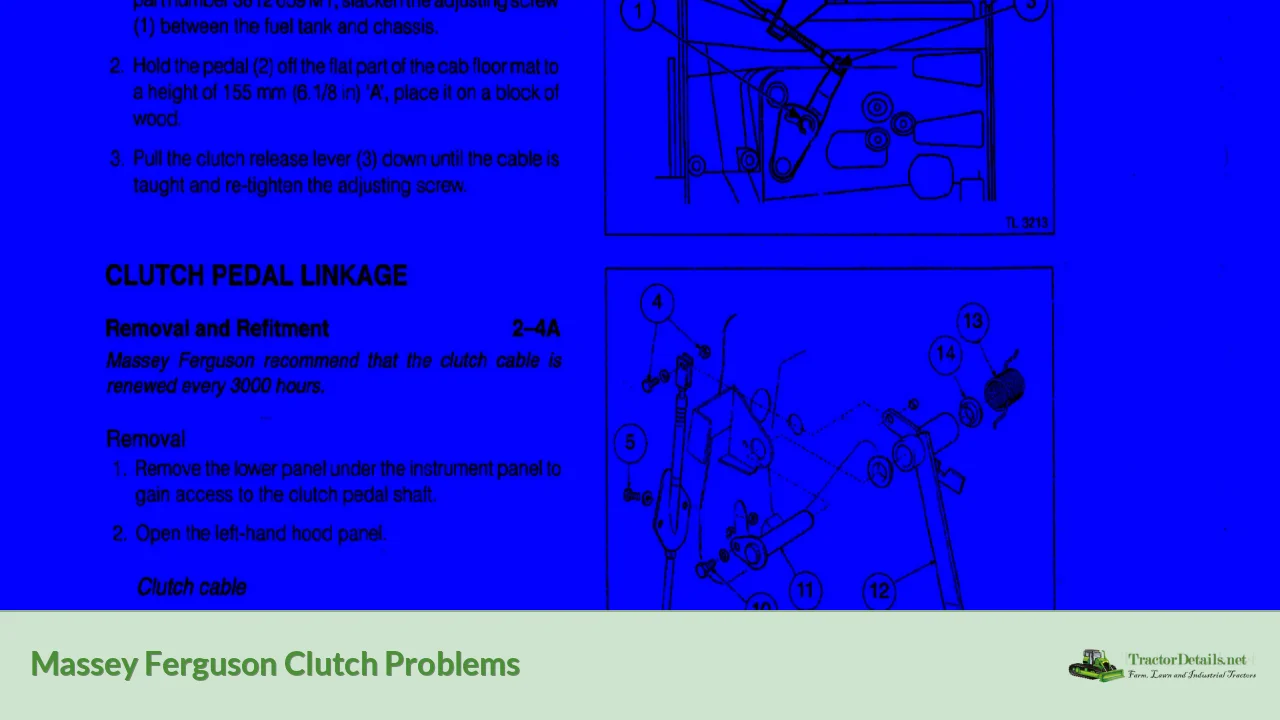

For Misadjusted Clutch Linkage:

- DIY Solution:

- Adjust the linkage according to the manufacturer's specifications.

- Professional Repair:

- A professional can ensure correct alignment and adjustments for optimal performance.

For Damaged Release Bearing:

- DIY Solution:

- Replace the release bearing if you have the tools and skills required.

- Professional Repair:

- If you are unsure, it is best to let a professional handle this to avoid further damage.

Estimated Repair Costs

The costs associated with clutch repairs can vary widely based on the severity of the problem, availability of parts, and labor costs in your location. Here’s a rough estimate of what you might expect:

-

DIY Repairs:

- Worn clutch plates: $200 - $500 (for parts only)

- Hydraulic fluid: $100 - $200 (for fluid only)

- Miscellaneous parts (bolts, seals): $50 - $150

-

Professional Repairs:

- Complete clutch replacement: $800 - $2,500 (depending on model and labor rates)

- Hydraulic system service: $300 - $800

Prevention Tips

Prevention is better than cure. Regular maintenance and checks can save you from expensive repairs later. Here are some preventive measures:

-

Regular Inspections:

- Schedule bi-annual inspections of the clutch and hydraulic systems.

-

Routine Fluid Changes:

- Change hydraulic fluid and filters according to the manufacturer's schedule to prevent contamination.

-

Proper Clutch Usage:

- Use the clutch properly during operation, avoiding excessive slipping while changing gears.

-

Monitor Performance:

- Pay attention to any changes in performance or unusual noises. Address issues immediately to prevent further damage.

When to Seek Professional Help

While many minor clutch issues can be addressed through DIY repairs, there are situations where professional help is warranted:

-

Inability to Diagnose the Problem:

- If you're unsure about the source of the problem, it's best to consult a professional.

-

Complex Repairs:

- Repairs that involve significant disassembly or specialized knowledge should be left to qualified technicians.

-

Time Constraints:

- If you need to get your tractor back in service quickly, a professional service may be the best option.

Conclusion

Clutch problems in Massey Ferguson tractors can hinder performance and operational efficiency, making swift identification and repair essential. By recognizing symptoms early, understanding possible causes, and following proper diagnostic and repair procedures, you can maintain the functionality of your tractor effectively. Remember to invest in regular maintenance and use your tractor correctly to minimize wear and tear on the clutch system.

In summary, if you notice any clutch-related issues, don't hesitate to take action. Whether you opt for DIY repairs or professional assistance, addressing these problems promptly can save you time and money in the long run.It seems you might want to pick up on a topic or conversation. Could you please provide a bit more context or clarify what you'd like to continue discussing?