Massey Ferguson models are renowned for their reliability and resilience, but like any machinery, they can experience lift pump problems that hinder performance. A lift pump is critical for the efficient operation of hydraulic systems, ensuring fuel and hydraulic fluid are delivered where needed. When issues arise, they can lead to decreased performance and potential damage if not addressed promptly. Understanding the common symptoms and causes of lift pump problems in Massey Ferguson equipment allows operators to take quick action to rectify the situation.

Key Takeaways

- Lift pump issues in Massey Ferguson can significantly affect performance.

- Common symptoms include hard starts, engine stalling, and decreased hydraulic function.

- Regular maintenance and prompt diagnosis are essential for preventing lift pump problems.

- DIY troubleshooting can save on repair costs, but professional help should be sought for complex issues.

| Symptoms | Possible Causes |

|---|---|

| Hard starting | Clogged filters |

| Engine stalling | Air leaks in the fuel system |

| Decreased hydraulic power | Faulty lift pump |

| Unresponsive hydraulic controls | Blocked fuel lines |

| Excessive engine noise | Worn out lift pump components |

Problem Description

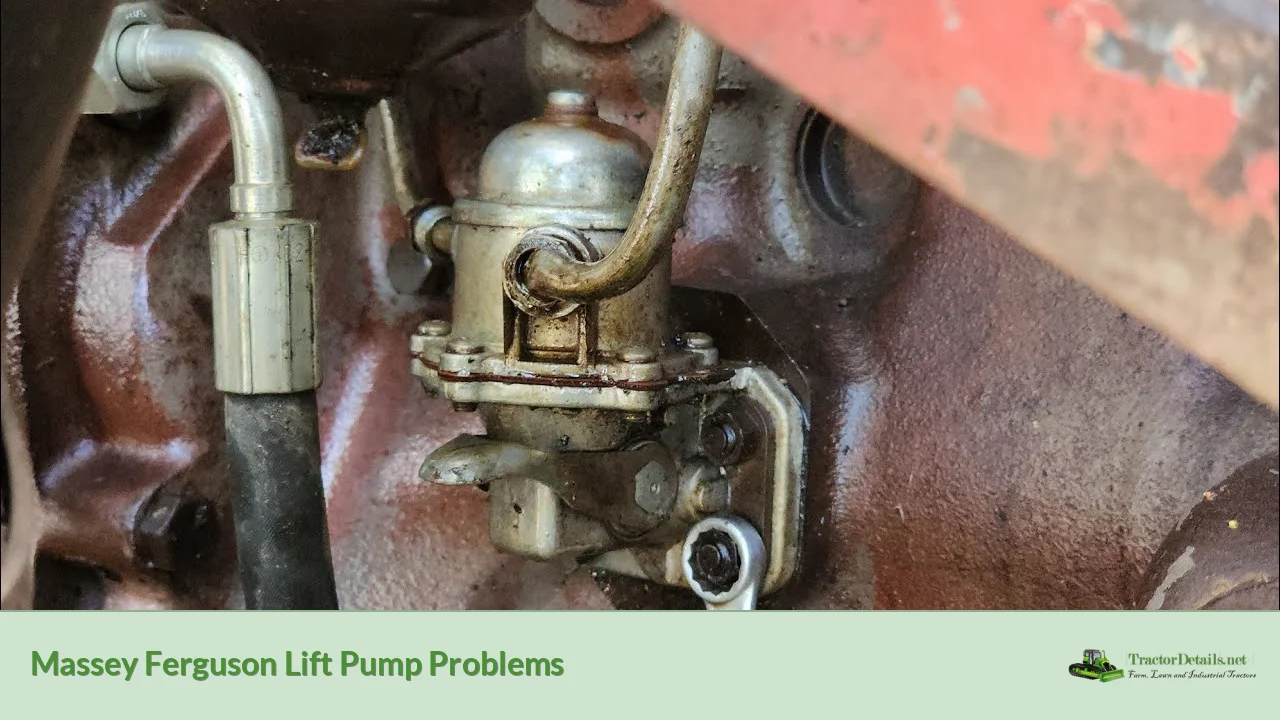

The lift pump in Massey Ferguson tractors and equipment functions as a key component in transferring fuel from the tank to the engine’s injection system or hydraulic fluid to crucial operating mechanisms. When the lift pump fails or operates inefficiently, the entire system can be compromised, leading to significant operational issues. Typical problems include reduced fuel flow, insufficient hydraulic pressure, and eventual engine failure if left unaddressed.

Common Symptoms

Identifying symptoms of lift pump problems early can save time and prevent costly repairs. Common signs include:

- Hard Starting: Difficulty starting the engine, particularly after extended idling or in cold weather.

- Engine Stalling: The engine stalling intermittently while operating, often due to fuel starvation.

- Decreased Hydraulic Power: Slow or unresponsive hydraulic actuators, impacting attachment operations.

- Unresponsive Hydraulic Controls: The inability to operate hydraulic attachments effectively.

- Excessive Engine Noise: A noticeable increase in engine noise that may indicate excess strain on the engine.

Possible Causes

Understanding the potential causes of lift pump issues is essential for troubleshooting. Here are some common factors:

- Clogged Filters: Dirt and debris can clog fuel filters, reducing flow to the lift pump.

- Air Leaks: Any leaks in the fuel line can introduce air, causing cavitation and inefficient operation.

- Faulty Lift Pump: Mechanical failures or wear in the lift pump itself can drastically reduce its effectiveness.

- Blocked Fuel Lines: Restrictions in the fuel lines can impede the flow from the tank to the pump.

- Electrical Issues: Problems with the electrical connections or supply to the lift pump can prevent it from operating.

Diagnosis Steps

To accurately diagnose lift pump issues, follow these steps:

-

Inspect Fuel Lines:

- Check for visible cracks, leaks, or damage along the fuel lines.

- Ensure all connections are secure.

-

Examine Fuel Filter:

- Inspect and replace clogged or dirty fuel filters.

- Make sure to check for the right fuel filter for your specific Massey Ferguson model.

-

Test Lift Pump Functionality:

- Verify lift pump functionality by checking output pressure using a gauge.

- Compare with specification values provided in the operator’s manual.

-

Check for Air Leaks:

- Conduct a visual inspection for air leaks in hoses and connections.

- You can use a smoke test or soap solution to identify leaks.

-

Check Electrical Supply:

- Evaluate the power supply to the lift pump. Use a multimeter to ensure adequate voltage is being supplied.

Troubleshooting and Repair Procedures

If diagnosis indicates that the lift pump is the issue, here are troubleshooting and repair procedures:

-

Replace Clogged Filters:

- Ensure proper part number matches your Massey Ferguson model.

- Install new filters according to the manufacturer’s specifications.

-

Repair or Replace Air Leaks:

- Replace any damaged hoses or tight connections as needed.

- Use high-quality sealants for connections that show signs of wear.

-

Lift Pump Replacement:

- If the lift pump is faulty, locate the pump (usually found near the fuel tank).

- Disconnect the battery and drain the fuel system before replacement.

- Remove the faulty pump and install a new one, ensuring all connections are secure.

-

Electrical Repairs:

- Secure or replace damaged wires and connectors to ensure proper electrical supply.

- Test the circuit for continuity after repairs.

Estimated Repair Costs

Repair costs can vary widely depending on the nature of the problem and whether you choose to repair it yourself or enlist professional services. Typical costs include:

- DIY Repairs: Basic repairs such as filter replacements or checking connections may cost between $30-100 for parts.

- Lift Pump Replacement: If the lift pump needs replacement, the part may cost between $150-500.

- Professional Labor: Hiring a technician may add $75-150 per hour, depending on the complexity of the repair.

It’s wise to obtain an estimate before proceeding, particularly for extensive repairs.

Prevention Tips

To avoid lift pump problems, consider implementing the following maintenance tips:

- Regular Maintenance: Schedule regular inspections and maintenance services as per the Massey Ferguson owner manual.

- Fuel Quality Control: Use quality fuel to prevent contamination and wear on the lift pump and other components.

- Direct Usage: Keep equipment in good condition and store it in a climate-controlled environment if possible.

- Avoid Running on Empty: Keep fuel levels adequate, as running low can draw contaminants into the fuel lines and pump.

When to Seek Professional Help

While many lift pump issues can be diagnosed and addressed by the owner, some symptoms may indicate deeper mechanical issues that require professional expertise. If you encounter any of the following scenarios, consider seeking professional assistance:

- Persistent hard starting after troubleshooting.

- Recurring engine stalling despite pump replacement.

- Severe hydraulic malfunctions indicating potential internal system failure.

- Lack of confidence in performing intricate mechanical repairs.

Conclusion

Lift pump problems in Massey Ferguson equipment can lead to significant operational issues, but with proper knowledge and maintenance, many problems can be prevented or easily rectified. Recognizing symptoms early and understanding possible causes are keys to effective troubleshooting. From simple filter replacements to complete pump modifications, being proactive about maintenance can save you time and money in the long run. Remember, if ever in doubt about your machin’s health or repair methods, seek professional assistance to ensure thorough and safe repairs. Proper care of your Massey Ferguson lift pump is essential to maintain its performance and reliability.It seems like your message was incomplete or you're requesting to continue a conversation or topic. Could you please provide more details or specify what you'd like me to continue with? This could be a previous discussion, a story, information on a specific topic, or something else entirely. Let me know how I can assist you!