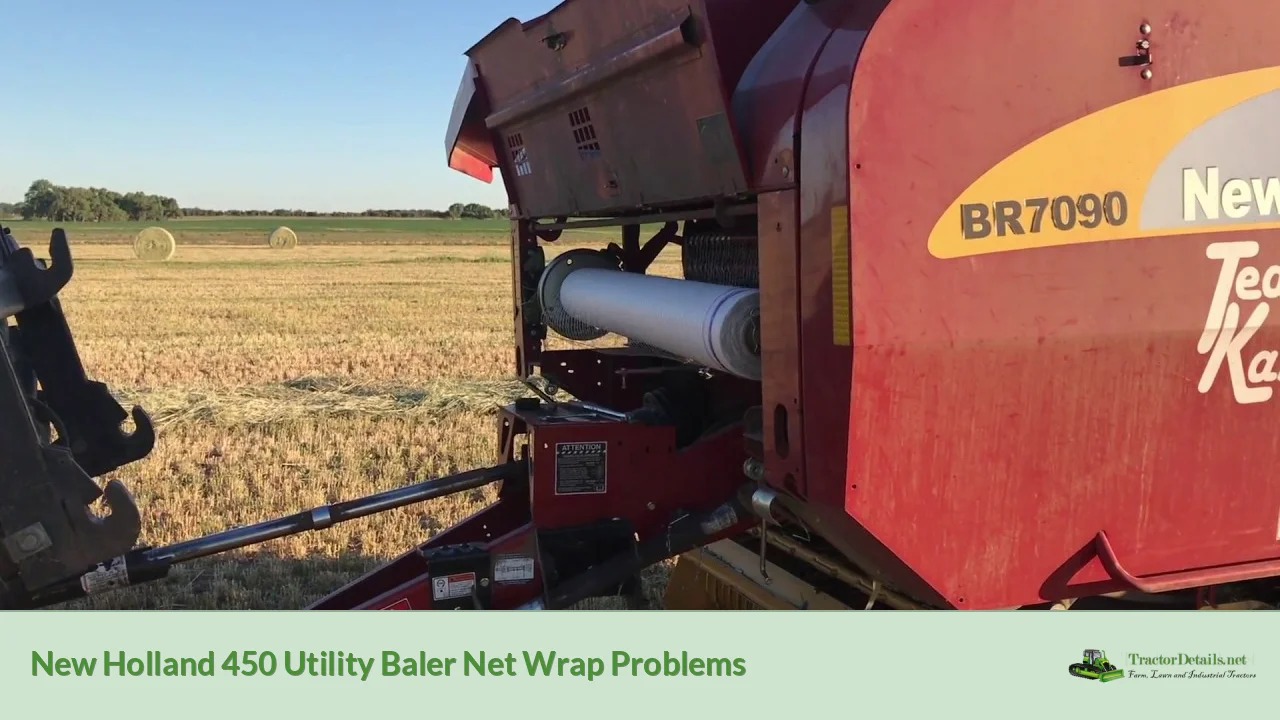

Overview of the New Holland 450 Utility Baler Net Wrap Problems

The New Holland 450 Utility Baler is a trusted machine in the agricultural sector, known for its reliability and efficiency in baling various materials. However, like any piece of machinery, it can encounter issues, particularly with the net wrap system. Problems with the net wrap can lead to inefficient baling, increased downtime, and costly repairs. Understanding these issues is crucial for maintaining optimal performance and extending the lifespan of the baler.

| Symptoms | Possible Causes |

|---|---|

| Inconsistent wrapping | Worn net wrap components |

| Net wrap breaking | Incorrect tension settings |

| Poor bale shape | Misalignment of components |

| Error codes displayed | Sensor failure or blockage |

| Frequent misfeeds | Dirty or damaged rollers |

Key Takeaways

- Net wrap issues can significantly impact baling efficiency and quality.

- Regular maintenance and inspections can help prevent many problems.

- Identifying symptoms early can save time and costs associated with repairs.

- Both DIY solutions and professional repairs are available for net wrap problems.

Problem Description

The New Holland 450 Utility Baler uses a net wrap system designed to secure the contents of bales tightly. However, several issues can arise, affecting its overall functionality:

- Net Wrap Breakage: This occurs when the net wrap does not hold, leading to incomplete baling.

- Increased Tension Requirements: Sometimes, the net wrap will require higher tension settings, which can indicate underlying problems.

- Misalignment: Components within the net wrap system can become misaligned, causing uneven wrapping.

- Shortage of Net Material: Running out of net material can lead to improper baling techniques.

These issues, if not addressed promptly, can lead to decreased efficiency and increased operational costs.

Common Symptoms

Recognizing the symptoms of net wrap problems is essential for ensuring the New Holland 450 operates effectively. Some common signs include:

- Inconsistent wrapping: Bales may have loose or uneven wraps, affecting their integrity.

- Net wrap breaking: Frequent breakage of net wrap material can be observed.

- Poor bale shape: Bales may appear improperly formed or inconsistent in size.

- Error codes displayed: The baler may present error codes related to net wrap functionality.

- Frequent misfeeds: Issues with feeding the net wrap into the system can occur, causing delays.

Summary of Symptoms

- Inconsistent wrapping can lead to material loss.

- Breakage of the wrap can indicate tension issues.

- Poorly shaped bales may result from misalignment.

- Error codes require immediate attention to avoid further damage.

- Misfeeds can signal dirt or damage in roller systems.

Possible Causes

Identifying the root causes of net wrap problems is essential for effective resolution:

- Worn net wrap components: Over time, components like rollers or tensioners may wear down, leading to ineffective wrapping.

- Incorrect tension settings: Tension may need adjustments based on materials being baled or environmental conditions.

- Misalignment of components: A slight misalignment can lead to significant wrapping issues.

- Dirty or damaged rollers: Debris or wear on rollers can cause feed errors and wrapping inconsistencies.

Diagnosis Steps

To effectively diagnose net wrap problems in the New Holland 450 Utility Baler, follow these steps:

- Visual Inspection: Examine the net wrap system for obvious signs of wear or damage.

- Check Tension Settings: Refer to the operator's manual for the correct tension settings and adjust if necessary.

- Test Wrap Function: Run a test operation with the baler to observe the wrapping process.

- Inspect Rollers and Guides: Clean and inspect rollers for dirt and damage.

- Listen for Unusual Noises: Pay attention to any unusual sounds that may indicate mechanical issues.

Key Points to Consider during Diagnosis

- Always ensure safety precautions are taken when working on machinery.

- Keep the baler clean to prevent debris build-up that can cause problems.

Troubleshooting and Repair Procedures

Once the diagnosis is made, follow these troubleshooting and repair procedures:

Step-by-Step Troubleshooting

- Tension Adjustments:

- Adjust the tension settings to manufacturer specifications.

- Component Replacements:

- Replace worn or broken components as identified during inspection.

- Realignment:

- Check all alignment settings and adjust components that are misaligned.

- Cleaning Procedures:

- Clean all rollers and feed areas to ensure smooth operation.

Repair Options

- DIY Repairs:

- Many minor adjustments and replacements can be done by skilled operators with basic tools. Ensure a thorough understanding of the machine's specific parts via the operator’s manual.

- Professional Services:

- For complex issues or significant repairs, consult a professional service technician familiar with New Holland equipment.

Estimated Repair Costs

Repair costs can vary widely based on the nature of the issue:

- Basic Adjustments: $50 to $200 for minor settings changes and cleaning.

- Component Replacement:

- Rollers: $100 to $300

- Tensioners: $150 to $400

- Professional Repair Services: Labor costs may range from $75 to $150 per hour, depending on the complexity of the repairs required.

Regular maintenance can reduce overall repair costs by preventing major breakdowns.

Prevention Tips

To prevent net wrap issues in the New Holland 450 Utility Baler:

- Routine Maintenance: Schedule regular inspections and maintenance to catch problems early.

- Proper Storage: Store the baler and net wrap materials in a dry, protected environment to prevent moisture damage.

- Operator Training: Ensure operators are trained to recognize early signs of trouble and adjust settings accordingly.

- Quality Materials: Use high-quality net wrap materials that are compatible with the baler.

When to Seek Professional Help

- Complex Diagnostics: If troubleshooting steps do not resolve the issue, professional help may be necessary.

- Error Codes: Persistent error codes should be reviewed by a technician.

- Large Repairs: If significant parts require replacement or if there is uncertainty in performing repairs, seek assistance.

Conclusion

Understanding net wrap problems in the New Holland 450 Utility Baler is crucial for efficient operation. By being aware of symptoms, possible causes, and effective diagnosis and repair steps, owners can minimize downtime and maintain productivity. Regular maintenance and proactive measures can go a long way in preventing these issues.

For optimal performance, always follow the manufacturer’s guidelines and don’t hesitate to reach out for professional help when needed. With the right approach, keeping your baler running smoothly becomes manageable, ensuring that your agricultural operations remain productive and cost-effective.It looks like your message was cut off! Could you please provide more details or clarify what you'd like to continue discussing?