The New Holland H8040 series is a powerful and versatile machine renowned for its efficiency and reliability in various agricultural tasks. However, like any complex piece of machinery, the H8040 is not without its problems. Owners have reported a range of issues that can hinder performance, lead to costly repairs, and require careful attention to maintain optimal operation. Understanding these problems, their symptoms, and their underlying causes is crucial for effective maintenance and repair.

Key Takeaways

- The New Holland H8040 can experience multiple issues, notably related to hydraulic systems, engine performance, and electronic components.

- Common symptoms include unusual noises, decreased performance, and frequent error codes.

- Proper diagnosis and timely repair can prevent further complications and costly downtime.

- Regular maintenance plays a vital role in preventing known issues.

| Symptoms | Possible Causes |

|---|---|

| Decreased engine power | Clogged fuel filter, air intake issues |

| Unusual noises during operation | Worn bearings, failing hydraulic pumps |

| Frequent error codes | Faulty sensors, electrical wiring issues |

Problem Description

Owners of New Holland H8040 often experience problems ranging from minor inconveniences to significant operational failures. Among the most frequently reported issues are:

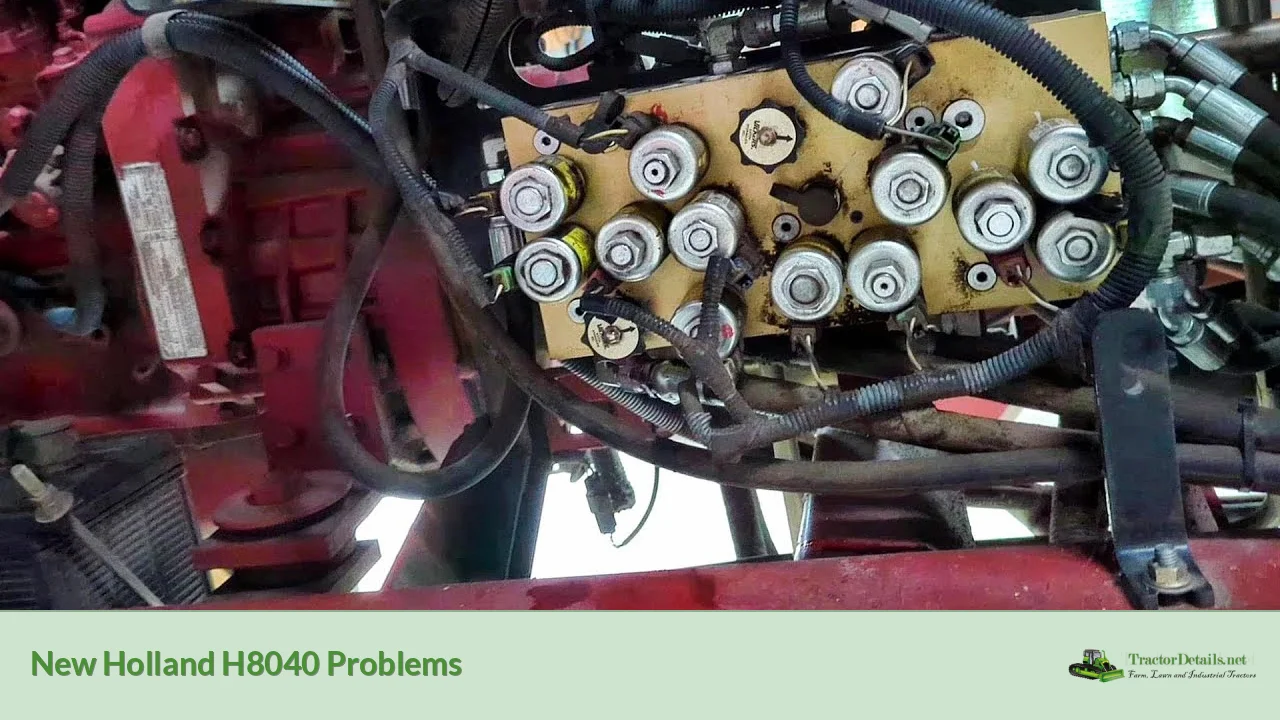

- Hydraulic system failures: This includes both lifting and steering systems.

- Engine troubles: Symptoms can vary from reduced power to stalling.

- Electrical issues: Including malfunctioning sensors and wiring problems.

Additionally, the machine's complexity means that diagnosing issues can be a challenge, often requiring specialized knowledge of hydraulic systems, engine mechanics, and electrical components.

Common Symptoms

Identifying symptoms early can help in preventing the escalation of issues. Here are some notable signs of problems in New Holland H8040 machines:

- Decreased engine performance:

- Lack of power when under load

- Difficulty starting the engine

- Hydraulic system issues:

- Slow response of hydraulic controls

- Hissing or whining noises from hydraulic lines

- Electrical problems:

- Inconsistent readings from gauges

- Warning lights on the dashboard

- Unusual sounds:

- Grinding or clinking noises during operation

- Knocking sounds from the engine

Possible Causes

Several underlying causes could lead to the aforementioned symptoms. Identifying the specific cause is important for effective troubleshooting.

-

Engine Problems:

- Clogged fuel filter: Impedes fuel flow and affects performance.

- Air intake issues: Restrictions can lead to poor combustion.

-

Hydraulic System Failures:

- Worn or damaged hydraulic seals: Leads to fluid leaks and reduced system pressure.

- Low hydraulic fluid levels: May cause sluggish operation or failure of hydraulic components.

-

Electrical Issues:

- Faulty sensors: Errors in transmission signals can trigger warning lights.

- Corroded wiring connections: Leads to intermittent electrical faults.

Diagnosis Steps

Diagnosing the problems in a New Holland H8040 effectively requires a structured approach. Here are the recommended steps:

-

Visual Inspection:

- Check for visible leaks in hydraulic components.

- Inspect electrical connections for corrosion or damage.

-

Listening for Noises:

- Pay attention to any unusual sounds during operation.

- Identify whether sounds are consistent with specific actions (e.g., turning hydraulics on).

-

Error Code Retrieval:

- Use an OBD-II reader, if equipped, or consult the manual for specific error codes.

- Record error codes to assist in diagnosis.

-

Measurement of Fluid Levels:

- Check engine oil, hydraulic fluid, and coolant levels.

- Ensure that all fluids are at recommended levels as per the owner’s manual.

-

Test Operations:

- Conduct basic tests, such as operating the hydraulic lift and steering controls to observe behavior.

Troubleshooting and Repair Procedures

Once diagnosed, several troubleshooting methods can be employed based on the specific issues identified.

-

For Engine Performance Issues:

- Replace the fuel filter if clogged.

- Inspect and clean the air intake system.

-

For Hydraulic Failures:

- Replace worn seals within the hydraulic system.

- Top off or change hydraulic fluid when levels are low or fluid appears contaminated.

- Repair or replace damaged hydraulic hoses.

-

For Electrical Problems:

- Inspect and replace faulty sensors.

- Repair any corroded or loose wiring connections.

Note: Ensure all repairs comply with manufacturer guidelines to maintain warranty coverage and operational safety.

Estimated Repair Costs

Repair costs can vary significantly depending on the specific issue, parts needed, and whether you opt for professional assistance or a DIY fix.

-

DIY Repairs:

- Basic maintenance (e.g., fluid changes): $50 - $200, depending on materials needed.

- Sensor replacement: Parts range from $30 - $150.

-

Professional Repairs:

- Engine diagnostics: $100 - $300 based on service fees.

- Hydraulic system repairs: $500 - $2,000, depending on component failure severity.

Cost-Saving Tips:

- Perform routine maintenance to prevent larger issues and costs.

- Always compare prices on parts and labor across different service providers.

Prevention Tips

Preventive measures are crucial to extend the life of the New Holland H8040 and minimize unexpected breakdowns. Implement the following tips:

-

Regular Maintenance:

- Follow the manufacturer's recommended service schedule for oil changes, filter replacements, and hydraulic fluid checks.

-

Routine Inspections:

- Perform visual inspections every few weeks to catch issues early.

- Test all essential systems to ensure they are functioning correctly.

-

Proper Operation:

- Train operators on the correct use of the H8040 to prevent unnecessary stress on the machine.

- Avoid overloading the equipment beyond its rated capacity.

When to Seek Professional Help

While many minor repairs and maintenance tasks can be performed by owners, certain situations warrant professional intervention. Consider seeking professional help in the following scenarios:

- Persistent Error Codes: If error codes persist despite basic troubleshooting, a professional can perform a detailed system analysis.

- Complex Hydraulic Issues: Hydraulic system failures often require specialized tools and expertise that may go beyond DIY capabilities.

- Severe Engine Troubles: If the engine shows signs of significant performance issues or damage, a qualified technician should diagnose the problem to avoid further damage.

Conclusion

In summary, the New Holland H8040 is an efficient agricultural tool, yet it faces various potential issues that need careful monitoring. Understanding the common problems, their symptoms, and the timely steps for diagnosis and repair will enable owners to maintain their equipment effectively.

- Keeping an eye on regular maintenance can significantly reduce unexpected issues.

- When problems do arise, taking a systematic approach to diagnostics and repairs will save both time and costs.

- Finally, do not hesitate to seek professional help when faced with complicated repairs beyond your expertise.

By following these recommendations, H8040 owners can ensure their machinery remains operational and reliable for many seasons to come.It seems like your message got cut off. Could you please provide more context or clarify what you would like to continue discussing?