Are you experiencing problems with your New Holland PTO? If so, you're not alone. Many New Holland owners have encountered New Holland Pto Problems and have been left perplexed and frustrated by the lack of solutions. Fortunately, with the help of experienced mechanics and some research, you can identify and solve these problems, allowing you to return to work quickly.

⚡️Other article: New Holland Br780 Round Baler Problems

Identifying and Resolving New Holland PTO Problems

Are you having trouble with your New Holland PTO? It can be frustrating to experience, but you can fix it quickly with the proper knowledge and resources. This article explores the most common New Holland PTO problems and discusses how to identify and resolve them quickly and effectively. We'll provide detailed instructions and tips for troubleshooting and suggest experienced mechanics who can help with any repairs. Plus, we'll discuss potential implications and consequences related to the issue, so you can make sure you understand the bigger picture.

| Issue | Troubleshooting | Solution |

|---|---|---|

| PTO not engaging | Check for loose connections and inspect the PTO belt for wear and tear. | Tighten connections and replace the PTO belt if needed. |

| PTO shaft slipping | Check for worn or broken components, and inspect the splines for damage. | Replace worn or broken components and repair or replace the splines as needed. |

| PTO not spinning | Check wiring and fuses, and inspect the PTO clutch for signs of overheating. | Repair or replace faulty wiring and fuses, and replace the PTO clutch if needed. |

Common PTO Problems

Many New Holland owners have encountered PTO problems such as difficulty shifting gears, slow response time, and the PTO not engaging. These issues can be quickly identified and resolved with the help of experienced mechanics and a bit of research. Below are some of the most common PTO problems and their potential solutions.

Difficulty Shifting Gears

One of the most common problems with the New Holland PTO is difficulty shifting gears. This can be caused by worn or damaged parts, or a lack of lubrication. You should inspect the PTO parts and replace any damaged or worn parts to resolve this. Additionally, you should make sure the PTO is adequately lubricated.

Slow Response Time

Another common PTO problem is slow response time. Various issues, including air in the hydraulic system, low hydraulic fluid levels, or a faulty hydraulic pump, can cause this. To fix this, you should check the hydraulic system for air bubbles, top up the hydraulic fluid, and inspect the hydraulic pump for signs of damage.

🎯Suggested article: New Holland Powerstar 75 Problems

PTO Not Engaging

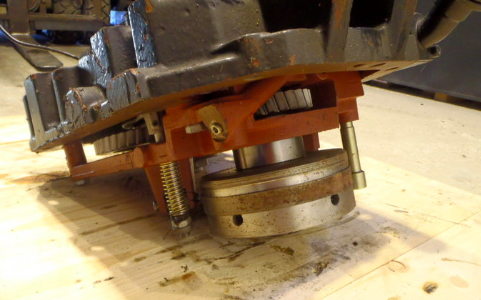

If the PTO is not engaging, the most likely cause is a faulty PTO clutch. To diagnose this, you should inspect the clutch for signs of damage or wear, and replace it if necessary. Additionally, you should check the wiring and connections to ensure they are properly seated and functioning correctly.

Key Takeaways for New Holland PTO Problems

- Common PTO problems include difficulty shifting gears, slow response time, and the PTO not engaging.

- To diagnose and address these issues, check for worn or damaged parts, inspect the wiring and connections, and replace the PTO clutch if necessary.

- Ensure the PTO is adequately lubricated and the hydraulic system has no air bubbles and the proper fluid level.

- Consult experienced mechanics to ensure the problem is accurately identified and resolved.

- Understand the potential implications and consequences related to the issue.

Wrapping Up New Holland PTO Problems

New Holland PTO problems can be daunting, but with the help of experienced mechanics and a bit of research, they can be quickly identified and resolved. You can better diagnose and address these issues by understanding the most common issues, such as difficulty shifting gears, slow response time, and the PTO not engaging. To ensure the problem is accurately identified and resolved, it is essential to check for worn or damaged parts, inspect the wiring and connections, and replace the PTO clutch if necessary.

Additionally, ensure the PTO is adequately lubricated, the hydraulic system has no air bubbles, and the proper fluid level is. Finally, it is essential to consider the potential implications and consequences of any PTO issues and to consult experienced mechanics when needed. New Holland PTO problems can be effectively managed with the proper knowledge and support.

👀Look at this: New Holland T5 120 Problems