The effective operation of New Holland machinery, ranging from compact tractors to robust agricultural equipment, depends heavily on understanding and responding to warning light symbols. These symbols serve as quick diagnostic indicators, alerting operators to potential issues that may affect performance or safety. Familiarizing oneself with these symbols not only enhances operational efficiency but also reduces the risk of equipment damage and costly repairs. In this comprehensive guide, we will explore the significance of New Holland warning light symbols, their diagnostic implications, troubleshooting strategies, and preventive measures.

Key Takeaways

- Understanding warning light symbols is crucial for safe operation of New Holland equipment.

- Immediate attention to warning lights can prevent severe equipment damage.

- Regular maintenance and checks can minimize the risk of encountering warning symbols.

| Symptoms | Possible Causes |

|---|---|

| Engine doesn’t start | Faulty battery, fuel issues |

| Warning light flashing | Low oil pressure, high temperature |

| Drop in power | Clogged filters, fuel supply issues |

| Unresponsive controls | Electrical issues, software errors |

Problem Description

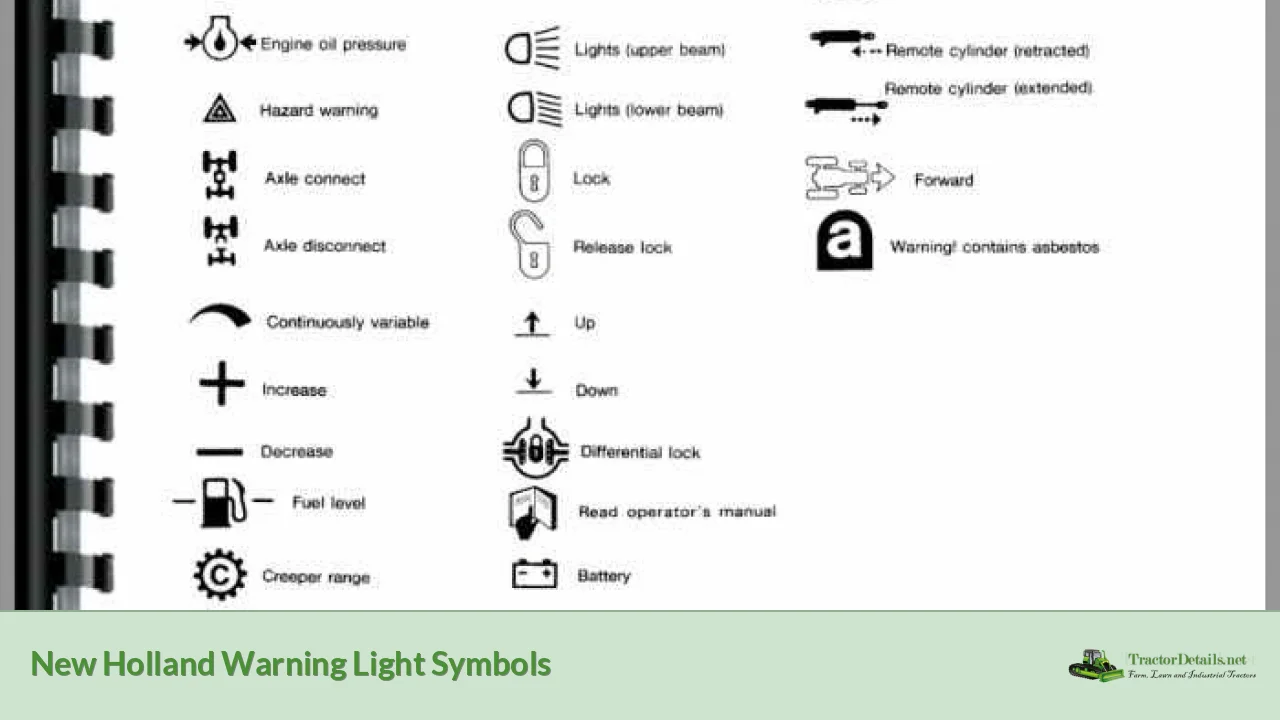

New Holland machinery utilizes a range of warning light symbols, each designed to alert operators about specific issues. These warning lights can indicate anything from simple operational cues to serious mechanical concerns. Common models, such as the New Holland T4, T5, and T6 series, employ distinctive symbols to communicate status effectively. Failing to acknowledge these alerts can lead to hardware malfunctions, increased repair costs, and even jeopardize operator safety.

Common Symptoms

Recognizing the symptoms that accompany warning light activation is essential for swift diagnosis. Some typical symptoms include:

- Flashing warning lights indicating immediate attention is required

- Engine performance issues such as stalling or reduced power

- Unresponsive controls or erratic behavior

- Unusual noises coming from the engine or machinery

- Erratic temperature readings on the engine gauge

Possible Causes

The following are probable causes behind the activation of New Holland warning light symbols:

- Electrical faults: Including battery failures, loose connections, or blown fuses.

- Fluid Levels: Low oil, coolant, or fuel can trigger warning lights.

- Mechanical issues: Engine wear, belt failures, or transmission problems.

- Sensor malfunction: Defective sensors may send false signals.

- Software glitches: In some modern machines, outdated software can cause electronic miscommunication.

Diagnosis Steps

Diagnosing the issue behind a warning light involves systematic checking. Follow these steps:

- Identify the warning light: Refer to the operator’s manual to understand the specific symbol.

- Check fluid levels: Ensure oil, coolant, and fuel are at required levels.

- Inspect electrical connections: Look for corroded terminals or loose wiring.

- Run self-diagnostics: Some models, particularly those with electronic controls, have built-in diagnostic capabilities.

- Check for stored error codes: Use diagnostic tools to retrieve any logged fault codes.

- Perform a visual inspection: Look for any visible damage or leaks.

Troubleshooting and Repair Procedures

Once diagnostic steps are completed, proceed with troubleshooting based on the findings. Here’s a general outline to address common issues:

-

Electrical Issues:

- Ensure battery connections are tight and corrosion-free.

- Replace blown fuses; consult the manual for specifications.

-

Fluid Level Warnings:

- Top off low fluids, especially oil and coolant. Use correct specifications from the manufacturer's guidelines.

-

Mechanical Problems:

- Inspect belts and pulleys; replace any worn components.

- Change clogged filters and check fuel supply lines for leaks.

-

Sensor Malfunctions:

- Use a multimeter to check sensor resistance.

- Replace faulty sensors, as indicated by diagnosis.

-

Software Glitches:

- Update software or perform resets according to manufacturer guidelines.

For complex repairs, such as engine overhauls or transmission servicing, it is advisable to consult a professional.

Estimated Repair Costs

Repair costs can vary significantly based on the issue's complexity, whether you opt for DIY or professional help. Below are some estimated costs:

- Simple electrical repairs (connections, fuses): $50 - $150

- Fluid changes (oil, coolant): $100 - $300

- Sensors replacement: $50 - $250 per sensor

- Mechanical repairs (belts, filters): $150 - $500

- Professional service for complex issues: $500 - $1500+

Always obtain multiple quotes from certified dealers or local repair shops to ensure competitive pricing.

Prevention Tips

Preventive maintenance is essential to minimize the occurrence of warning lights. Here are strategies to maintain your New Holland equipment effectively:

- Regular inspections: Schedule routine checks of all fluid levels and electrical systems.

- Follow a maintenance schedule: Adhere to manufacturer's recommendations for service intervals.

- Keep the operator's manual handy: Familiarize yourself with all symbols and instructions.

- Conduct pre-operation checks: Always inspect the machine before use to catch issues early.

- Educate operators: Ensure everyone who uses the equipment understands the importance of responding to warning lights.

When to Seek Professional Help

While many issues can be diagnosed and repaired by an owner, certain situations warrant professional intervention:

- Unidentified issues: If a warning light persists despite troubleshooting efforts.

- Complex repairs: When expertise or special tools are required.

- Engine or transmission issues: For safety and functioning repairs on critical systems.

- Electrical issues: When diagnostics point to potential electrical failures.

Ignoring warning lights can result in further damage and higher repair costs, so timely attention from a professional is crucial.

Conclusion

In conclusion, awareness of New Holland warning light symbols is a vital aspect of safely operating your machinery. Understanding the symptoms associated with these lights, diagnosing possible causes, and executing timely troubleshooting can save you from costly repairs and downtime. Always prioritize preventive maintenance and seek professional assistance when necessary.

By following these guidelines, operators can enhance the longevity and efficiency of their New Holland equipment, ensuring it remains in optimal working condition.Of course! What would you like to continue with? Please provide more details or context, and I'll be happy to help!