John Deere is a renowned name in the agricultural and machinery sectors, known for its high-quality equipment and engines. Understanding where John Deere engine parts are manufactured is essential for customers looking to maintain or repair their machinery. The company operates numerous manufacturing facilities worldwide, producing a wide range of engine components and parts tailored to various applications.

The production of John Deere engine parts is not limited to a single location; rather, it spans multiple countries, ensuring that the company meets global demand efficiently. This article will delve into the specific locations where John Deere engine parts are made, the types of parts produced, and the manufacturing processes involved.

| Location | Type of Parts Produced |

|---|---|

| Waterloo, Iowa, USA | Engines and agricultural tractors |

| Saran, France | Engines (95-250hp) |

| Greeneville, Tennessee, USA | Lawn and garden tractor components |

| Mannheim, Germany | Agricultural tractors and components |

| Dewas, India | Agricultural tractors and engines |

| Saltillo, Mexico | Engines and construction equipment parts |

| Harbin, China | Agricultural tractors and engines |

Overview of John Deere Manufacturing Facilities

John Deere maintains a vast network of manufacturing facilities across the globe. These facilities are strategically located to optimize production efficiency and meet regional demands. Each location specializes in different aspects of production, which allows John Deere to provide a comprehensive range of products.

The Waterloo facility in Iowa is one of the largest manufacturing sites for John Deere. It plays a critical role in producing engines and agricultural tractors. The facility is equipped with advanced technologies that ensure high-quality output while adhering to strict environmental standards.

In Saran, France, John Deere focuses on producing engines ranging from 95 to 250 horsepower. This facility is known for its precision engineering and rigorous testing processes that ensure reliability and performance.

The Greeneville plant in Tennessee specializes in components for lawn and garden tractors. This facility emphasizes quality control and efficient production methods to meet high consumer expectations.

In Mannheim, Germany, John Deere manufactures both tractors and various components essential for their operation. This facility is notable for its advanced assembly lines that produce a significant number of tractors daily.

Additionally, factories in Dewas, India, Saltillo, Mexico, and Harbin, China contribute to the global supply chain by producing various agricultural engines and parts tailored to local markets.

Types of Engine Parts Manufactured

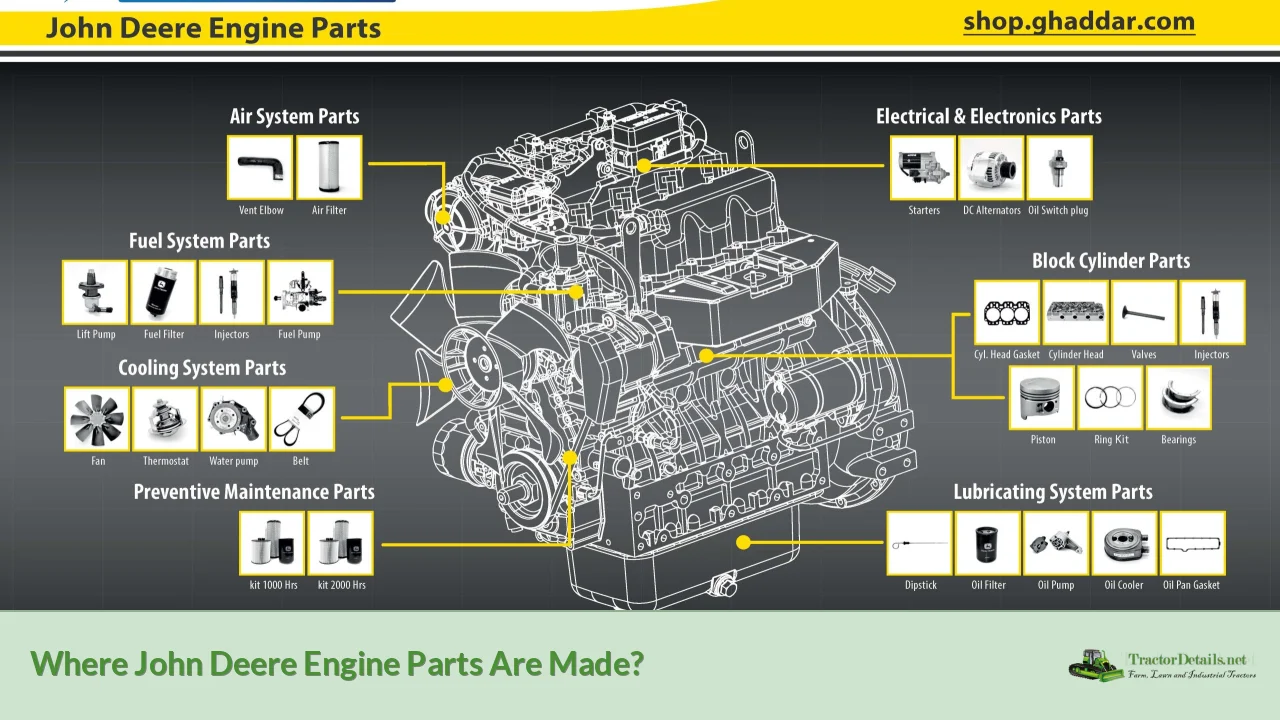

John Deere produces an extensive range of engine parts across its facilities. These include:

- Complete Engines: Fully assembled engines designed for specific models.

- Engine Components: Individual parts such as pistons, crankshafts, and cylinder heads.

- Drivetrain Parts: Components that facilitate power transmission within machinery.

- Remanufactured Parts: Used parts that have been restored to meet original specifications.

Each type of part undergoes rigorous testing to ensure it meets John Deere's high standards for quality and performance. The remanufacturing process is particularly noteworthy as it allows customers to obtain genuine John Deere parts at a reduced cost while maintaining quality.

Manufacturing Processes at John Deere

John Deere employs advanced manufacturing processes to produce its engine parts. These processes include:

- Precision Machining: Utilizing CNC machines to create components with exact tolerances.

- Assembly Lines: Streamlined assembly lines that enhance production efficiency.

- Quality Control: Comprehensive quality checks at each stage of production ensure that every part meets stringent specifications.

- Additive Manufacturing: Recently introduced technologies like 3D printing are being used for specific components to reduce costs and improve efficiency.

The integration of these processes allows John Deere to maintain its reputation for producing reliable and durable machinery.

Global Supply Chain Management

John Deere's global supply chain management plays a crucial role in ensuring timely delivery of engine parts. The company has established centralized warehouses in the United States and Europe, along with numerous depots worldwide. This network enables quick access to genuine parts for customers regardless of their location.

The company's commitment to customer service is evident through its ability to provide overnight delivery options in many areas. This responsiveness is vital for customers who rely on their equipment for critical operations.

Innovations in Engine Parts Manufacturing

John Deere continuously seeks innovative solutions to enhance its manufacturing capabilities. One significant development is the use of metal additive manufacturing, which allows for the production of complex engine components with reduced material waste. For instance, the company has successfully produced stainless steel valves using this technology, resulting in a more efficient production process.

This innovative approach not only lowers costs but also improves the performance characteristics of certain parts by allowing for intricate designs that were previously impossible with traditional manufacturing methods.

Environmental Considerations

As part of its commitment to sustainability, John Deere has implemented various environmental initiatives within its manufacturing processes. These include:

- Reducing emissions from production facilities.

- Implementing recycling programs for materials used in manufacturing.

- Utilizing energy-efficient technologies in plants.

These efforts reflect John Deere's dedication to minimizing its environmental footprint while still delivering high-quality products.

FAQs About Where John Deere Engine Parts Are Made

FAQs About Where John Deere Engine Parts Are Made

- Where are most John Deere engine parts manufactured?

Most engine parts are manufactured in facilities located in the USA, France, India, Mexico, and China. - What types of engine components does John Deere produce?

John Deere produces complete engines, individual components like pistons and crankshafts, drivetrain parts, and remanufactured parts. - How does John Deere ensure the quality of its engine parts?

John Deere employs rigorous testing procedures at each stage of production to ensure all parts meet strict quality standards. - What innovations has John Deere introduced in engine part manufacturing?

John Deere has adopted metal additive manufacturing techniques to produce complex components more efficiently. - How quickly can I receive replacement engine parts from John Deere?

Many locations offer overnight delivery options for genuine replacement parts.

In conclusion, understanding where John Deere engine parts are made provides valuable insight into the company's operations and commitment to quality. With a robust global manufacturing network and innovative practices, John Deere continues to be a leader in the agricultural machinery industry. Whether you need complete engines or specific components, knowing the origins can help you make informed decisions about your equipment maintenance needs.