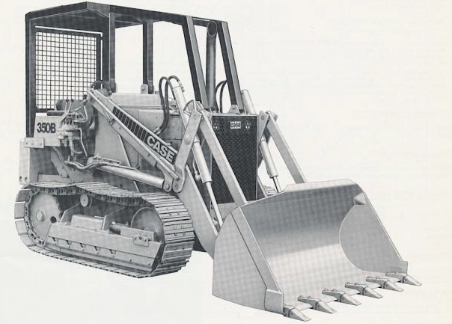

Case 350 dozer problems can be complex to diagnose and repair, but they can be quickly identified and resolved with the right knowledge and expertise. This comprehensive guide provides a detailed overview of the common problems associated with a Case 350 dozer. It offers helpful advice for diagnosing and fixing them to keep your equipment running efficiently.

🎯Suggested article: Case 450 Dozer Problems

Diagnosing and Fixing Common Case 350 Dozer Problems

This comprehensive guide provides an overview of the Case 350 Dozer and the common problems you may encounter with it. We explain how to diagnose and fix these issues, helping you keep your equipment running smoothly. We cover the most frequent problems, such as engine stalling, track slipping, and hydraulic system malfunctions, and offer advice on troubleshooting. We also discuss preventive maintenance recommendations and other valuable tips to help you avoid costly repairs. Finally, we provide a table with a detailed list of common dozer problems and their likely causes and solutions.

Power Train Issues

Case 350 dozer problems related to the powertrain can include various issues, such as a broken engine, transmission, or differential. Faulty parts or components and incorrect operating procedures can sometimes cause these issues. Diagnosing and repairing these problems requires a careful assessment of the system and a thorough understanding of the underlying causes.

Track System Issues

Case 350 dozers may also experience track system issues, such as broken or worn tracks, track linkages, or idlers. These problems can be caused by various factors, including improper maintenance, inadequate lubrication, or excessively rough terrain. To diagnose and repair these issues, it is important to inspect the components for signs of wear and tear and make sure the system is properly lubricated and maintained.

⚡️Another article: Case Cx37c Problems

Undercarriage Issues

Undercarriage issues are common in Case 350 dozers and can include problems with the rollers, sprockets, and pins. Various factors, including improper maintenance, incorrect operating procedures, or excessive wear and tear, can cause these issues. To diagnose and repair these problems, it is essential to inspect the components for signs of damage or wear and tear and make sure the system is properly lubricated and maintained.

Electrical System Issues

Case 350 dozer problems related to the electrical system can include faulty wiring, bad connections, or a broken alternator. Various factors, such as incorrect operating procedures or improper maintenance, can cause these issues. To diagnose and repair these problems, it is essential to inspect the system for signs of corrosion or wear and tear and make sure all components are correctly connected and functioning. The Case 350 dozer's alternator should also be checked for signs of damage or wear and tear.

The Case 350 dozer is a robust and reliable machine, but it can still experience various issues due to improper maintenance or incorrect operating procedures. To ensure that your sleeper runs efficiently, it is vital to know the common problems associated with the powertrain, track system, undercarriage, and electrical system. With the proper knowledge and expertise, these issues can be quickly identified and resolved, allowing the Case 350 dozer to operate at peak performance.

Critical Takeaways for Diagnosing and Fixing Common Case 350 Dozer Problems

- Frequent problems with the Case 350 dozer include engine stalling, track slipping, and hydraulic system malfunctions.

- Faulty parts or components and incorrect operating procedures can cause powertrain issues.

- Track system issues can be caused by improper maintenance, inadequate lubrication, or excessively rough terrain.

- Improper maintenance, incorrect operating procedures, or excessive wear and tear can cause undercarriage issues.

- Electrical system issues can be caused by incorrect operating procedures or improper maintenance.

- To ensure peak performance, it is essential to be aware of the common problems associated with the powertrain, track system, undercarriage, and electrical system.

- With the right knowledge and expertise, these issues can be quickly identified and resolved.

The concluding paragraph of this content should emphasize the importance of knowing the common problems associated with the Case 350 dozer and having the proper knowledge and expertise to diagnose and fix these issues. It should also encourage readers to be proactive and take the necessary steps to maintain their dozer at peak performance.

💥See also: Case Tv450 Problems

Achieving Optimal Performance with the Case 350 Dozer

A thorough understanding of the common problems associated with the Case 350 dozer is essential for achieving optimal performance. With the proper knowledge and expertise, these issues can be quickly identified and resolved, allowing the machine to operate efficiently. As such, it is vital to be proactive and take the necessary steps to ensure the dozer is appropriately maintained and operated, avoiding potential problems and ensuring it runs smoothly.