All trucks that are pulling trailers with air brakes must have a tractor protection system installed. This system consists of two components: the tractor protection valve and the trailer air supply valve. In order to ensure that this system is working properly, there are three test the tractor protection valve that should be performed.

The first test involves lowering the pressure in the system between 20 and 45 PSI (pounds per square inch). If done correctly, this process should cause the trailer air supply to shut off, thus cutting off all airflow to the trailer. The second test requires an inspection of the parking brakes on the trailer for proper application. Finally, after applying service brake from within the cab of truck, no additional air should be leaking out throught he tractor protection valve. Passing these three tests ensures proper functionality for both safety and efficiency purposes.

Overall, it is important for all trucks hauling trailers with air brakes equipped to have a functioning tractor protection system in place at all times in order to meet safety standards as well as maximize performance capabilities while on-the-road or job site. Read on for more detailed information.

What is The Tractor Protection Valve?

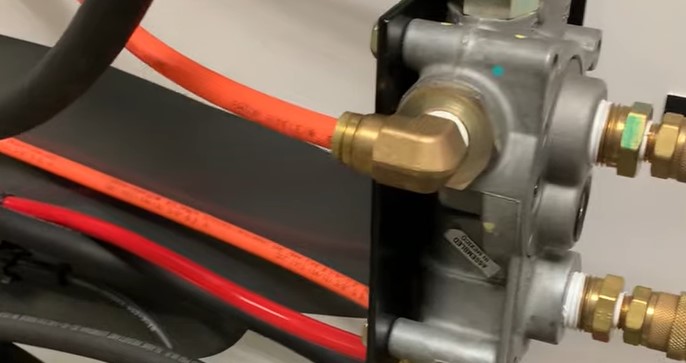

The tractor protection valve is an important component of a truck's trailer braking system. It is usually mounted on the cab or chassis of the tractor, and when the trailer-supply valve is open, air from the bottom of it charges up the supply line to 45 psi before allowing application air pressure to travel down to the trailer for brake applications.

When not hooked up to a trailer, however, no air will reach this valve as its service line port closes via spring pressure in order to protect any remaining application air pressure. In cases where there may be a breakaway from a trailer, the automatic closing feature of the supply line stops any further loss of air from both it and from within the truck itself.

Test The Tractor Protection Valve Steps

The tractor protection valve is an important safety feature on many towing vehicles. It prevents air loss problems in the trailer from causing a corresponding loss of air in the towing vehicle. To test that this system is working properly, certain steps must be taken, such as closing the trailer supply valve and disconnecting the service line. If any air escapes from this line while testing, it indicates that the protection valve is defective.

Carefully follow the steps below to test the tractor protection valve:

- Make sure all components are within normal operating pressure range.

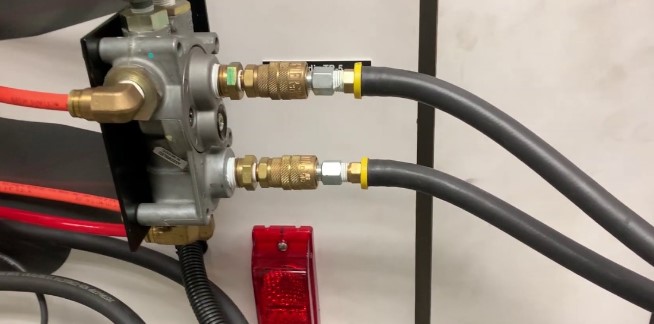

- Close the trailer supply valve; disconnect the trailer service-line coupler from either side.

- Press and hold down brake pedal (if there’s no anti-compounding valve).

- Observe whether any air exhausts from service-line coupler.

- A positive result means no air should escape during testing, indicating that everything is working properly and meeting legal requirements set out by Ontario Highway Traffic Act regulations.

It's essential for drivers to test the tractor protection valves regularly to make sure their vehicle meets safety standards and they won't be caught unawares on the road with a faulty one – potentially resulting in expensive fines or worse if something goes wrong while driving with an impaired system. Therefore it's best practice to thoroughly inspect your vehicle for signs of wear or damage before every journey so you can spot potential issues early and get them fixed promptly at a certified repair shop if necessary.

I have been using a tractor protection valve for quite some time now and I think it is necessary for everyone to perform regular tests on it. I have been able to identify problems with my valve before they become a real issue by testing it regularly. It is also important to inspect the parking brakes on the trailer for proper application, as this is a critical safety check. I have found that if you follow the steps carefully, it is not difficult to test the tractor protection valve. To make sure that you don't miss any steps, I would recommend watching a video tutorial or attending a workshop to learn more about testing the valve. It is also a good idea to ask questions to other drivers who have experience with the valve, as this can help you gain valuable insight.